Side-blowing fan

A side-blown fan and fan blade technology is applied to non-variable-capacity pumps, components of pumping devices for elastic fluids, pump devices, etc., and can solve problems such as pressure relief and inability to further increase wind pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

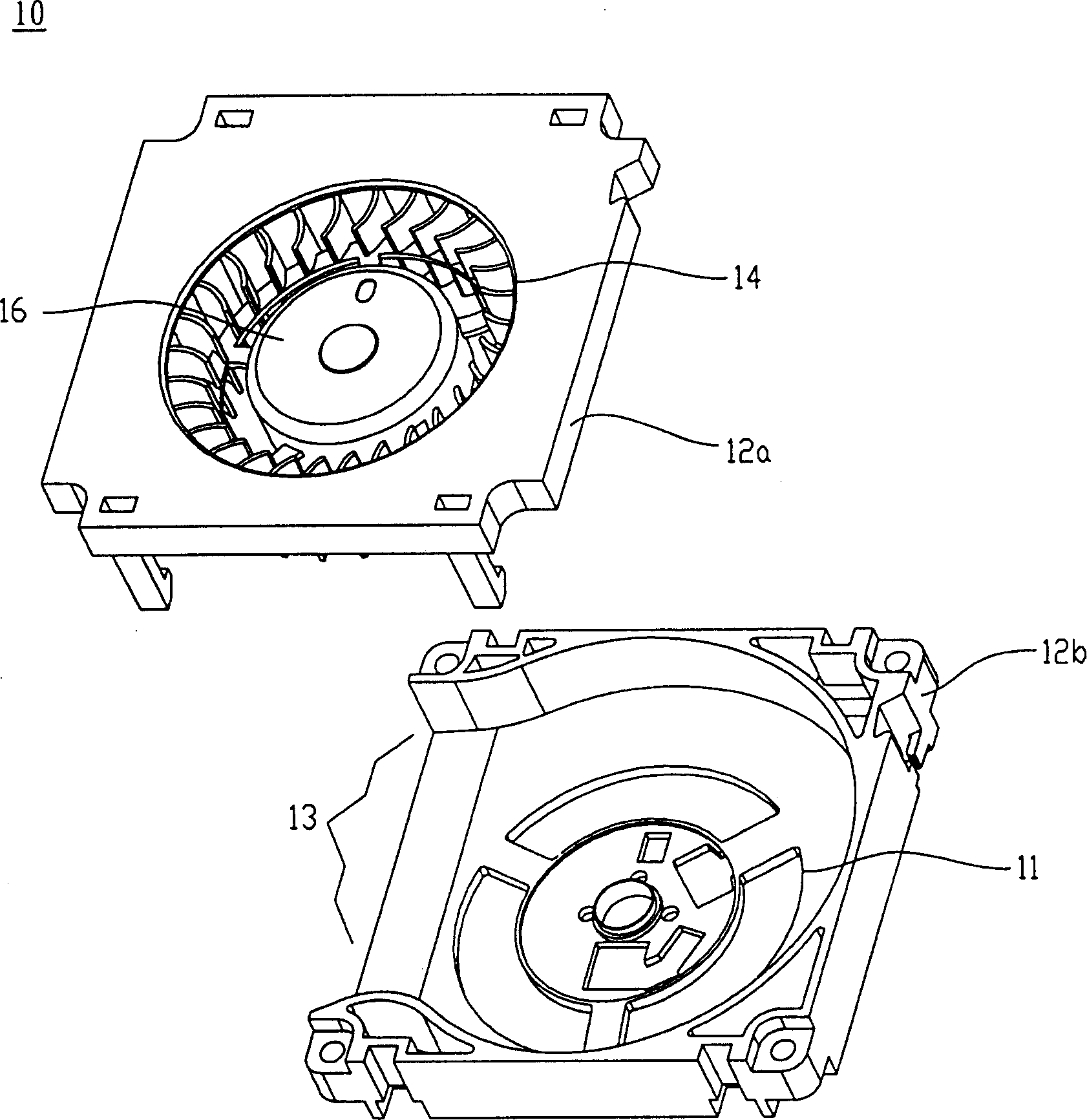

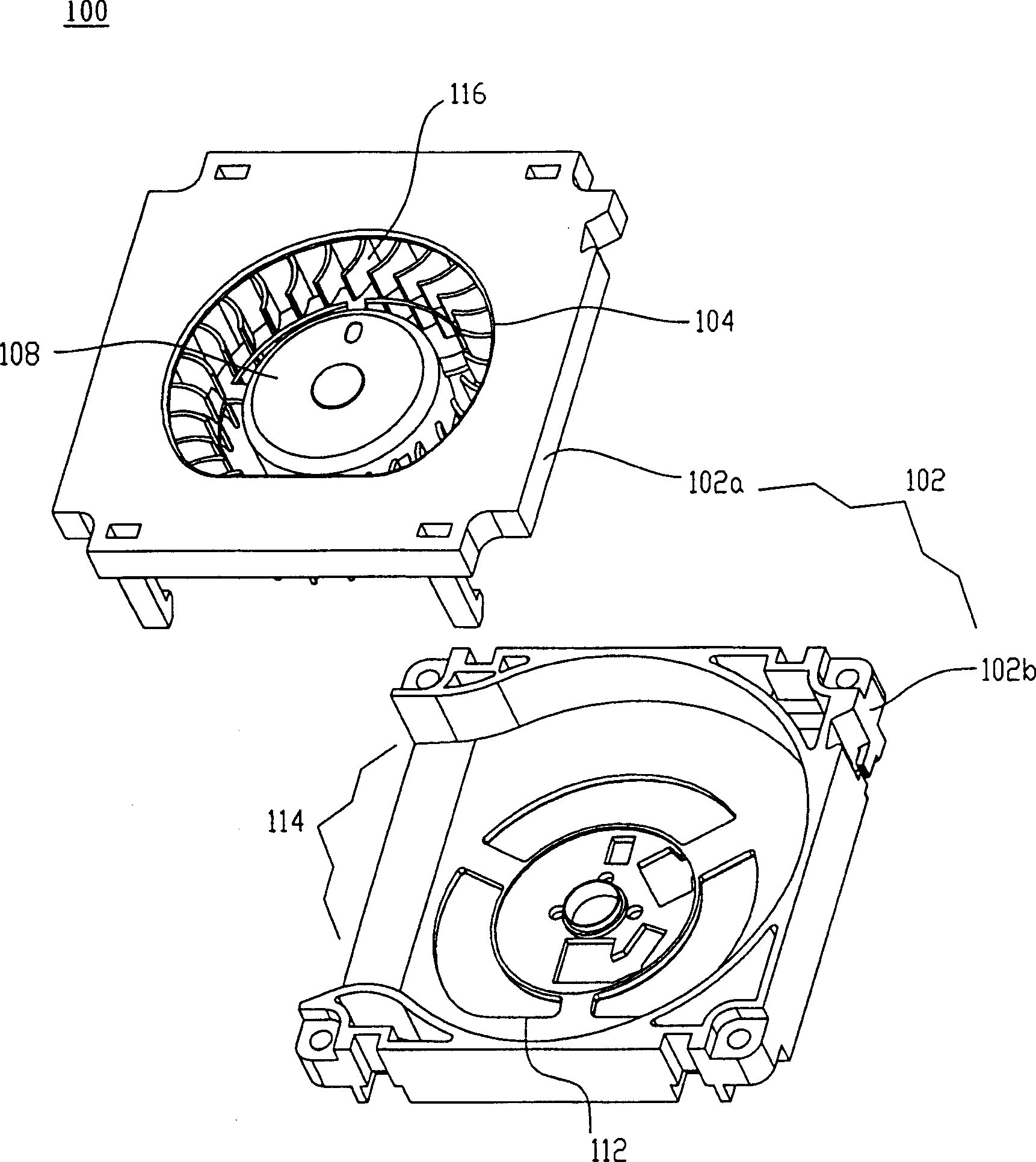

[0013] The present invention takes the form of a blower as an example to illustrate the side blowing fan of the present invention. Figure 2A Is a schematic diagram showing the side blowing fan 100 of the present invention, Figure 2B The figure is a perspective view of the present invention. Figure 4A , 4B Another embodiment of the present invention is shown.

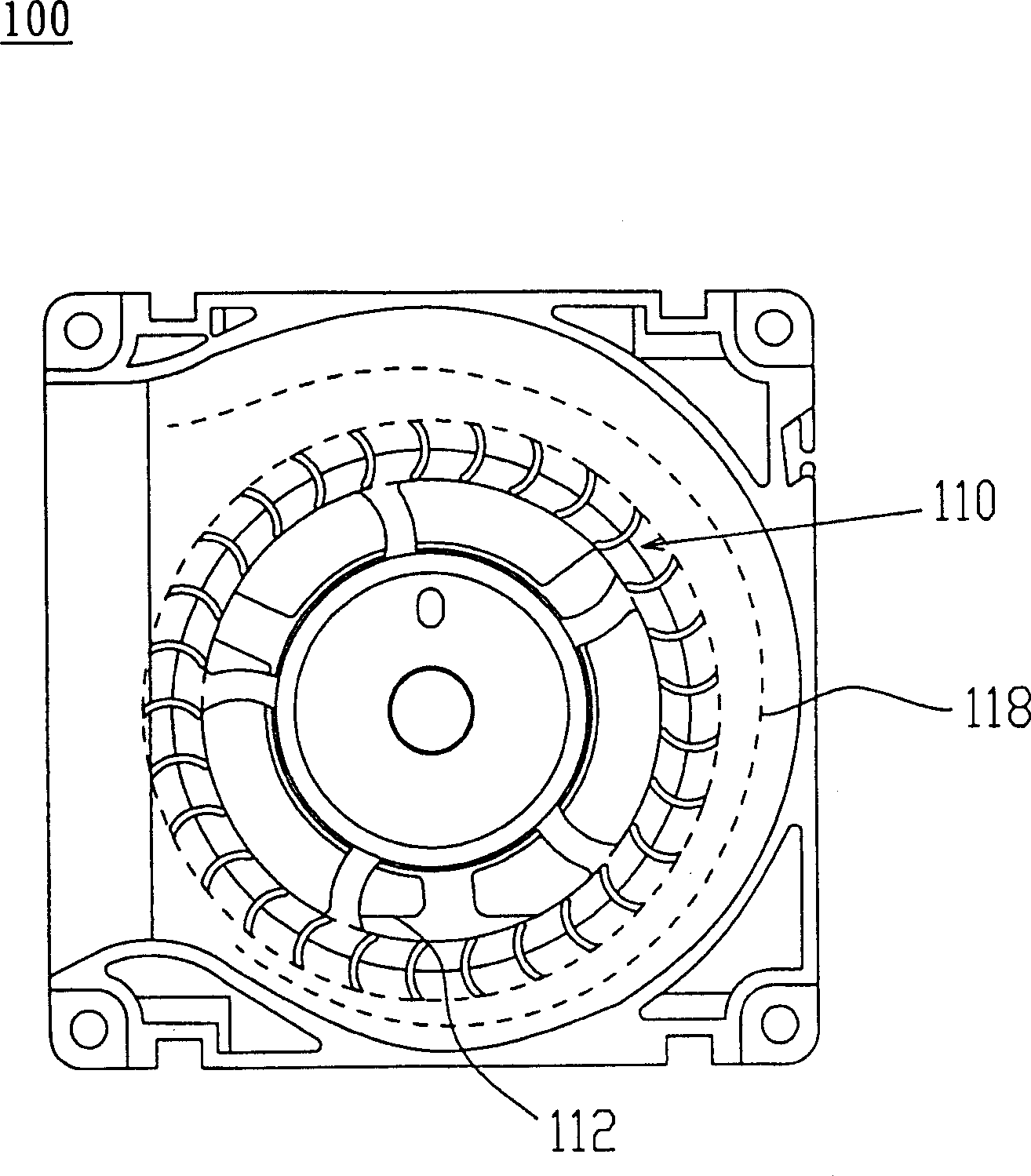

[0014] as Figure 2A , Figure 2B As shown, the side-blowing fan 100 is composed of a casing 102 and a fan blade member 108, and there is an air duct 118 between the fan blade member 108 and the casing 102.

[0015] The housing 102 has lateral air outlets 114 and axial air inlets 104 and 112. The shape of the axial air inlets 104 and 112 is cut round air inlets, such as Figure 3A The elliptical air inlet 106a shown, such as Figure 3B The polygonal air inlet 106b shown, such as Figure 3C The circular air inlet 106c which is not coaxial with the axis of the fan blade member 108 or the air inlet of any closed shape is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com