Rolling device

A technology of winding device and supporting wheel, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., and can solve the problems of large weight and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

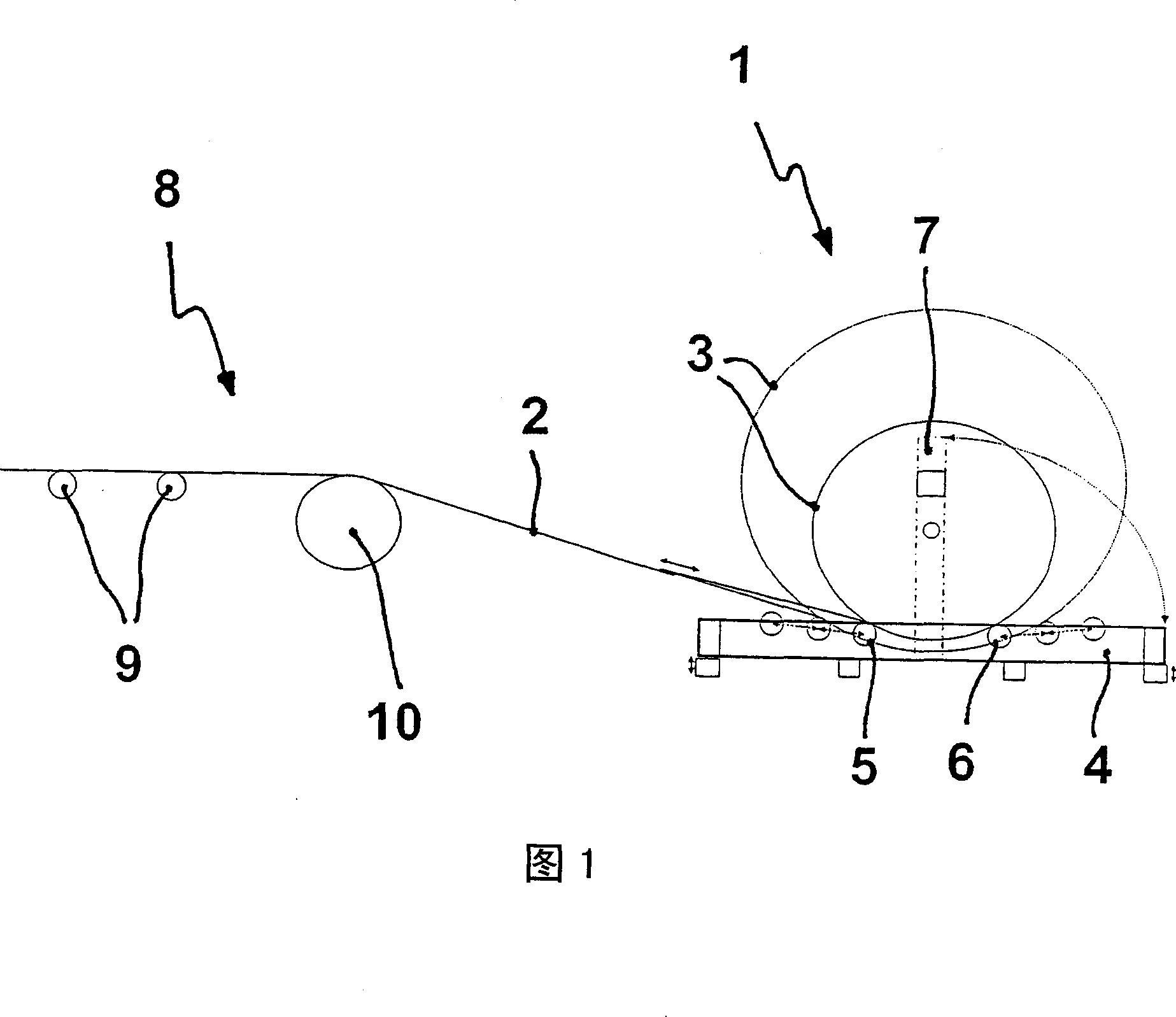

[0018] figure 1 The winding device for winding and unwinding the conveyor belt 2 is shown in , where the two directions of the belt are indicated by double arrows. The roll 3 is arranged on a base 4 . The base has two supporting wheels 5 and 6, which can be adjusted horizontally and vertically. The following will combine figure 2 The movement of the two support wheels (double arrows) on the base is described in detail.

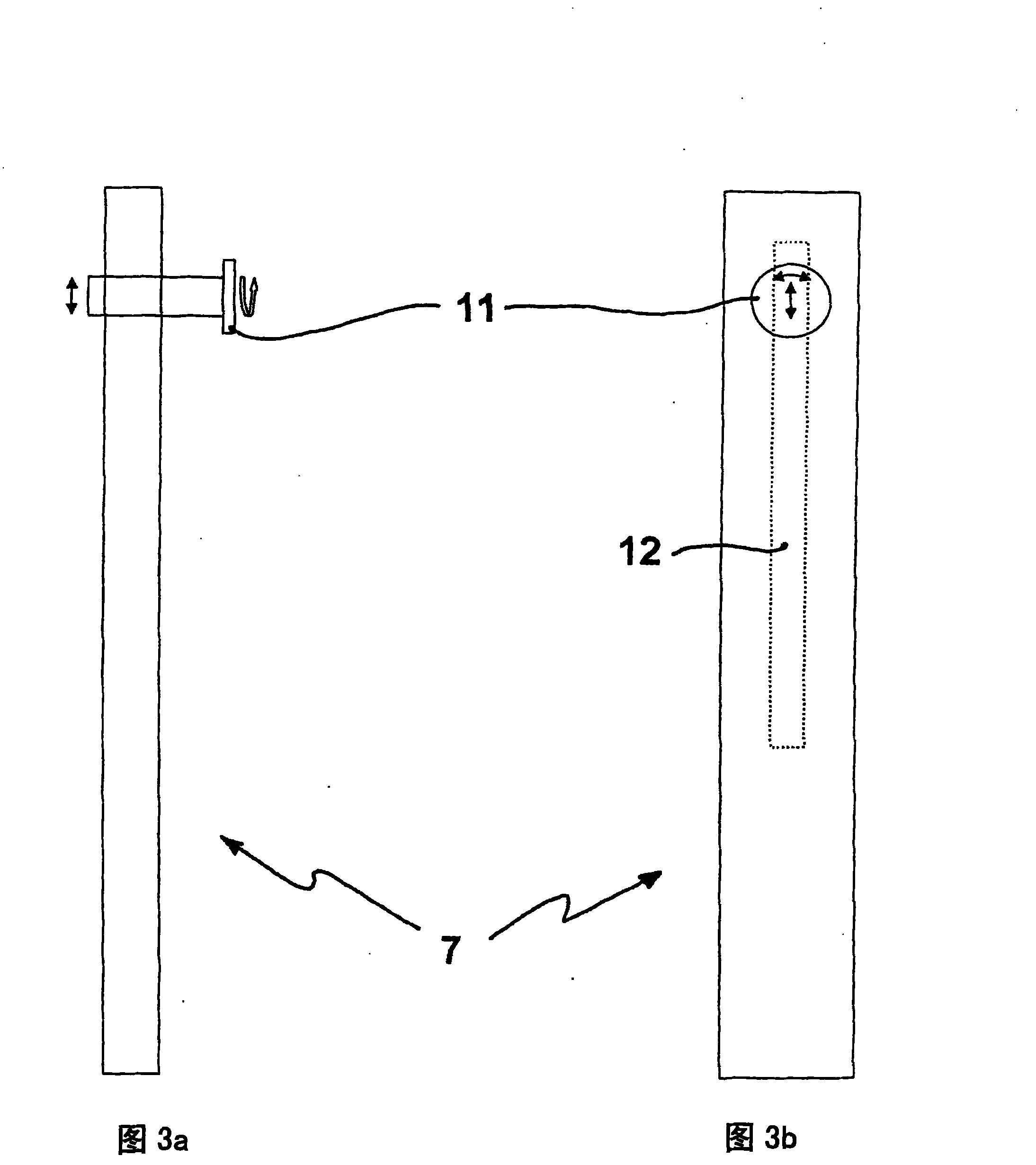

[0019] In addition, the winding device 1 has a side support 7, and the functional process of the support is also described in more depth in conjunction with the expressions in 2, 3a and 3b

[0020] The conveyor belt is guided on further support wheels 9 and deflection wheels 10 in the delivery or removal range 8 .

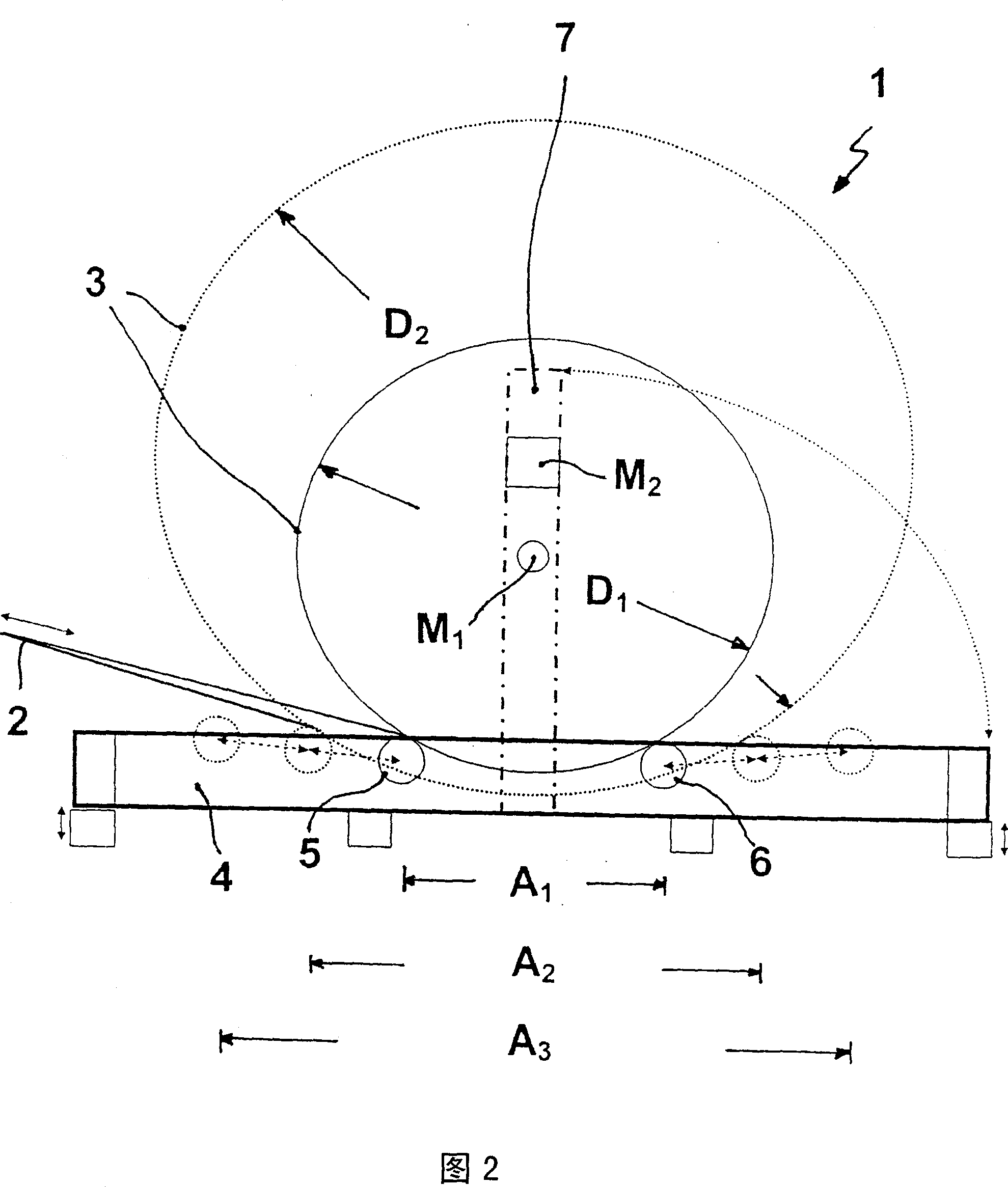

[0021] figure 2 Details of the base 4 of the winding device 1 are shown. Two supporting wheels 5 and 6 are separated from its winding diameter as D 1 The spacing A of windings 3 1 Make settings (reference point: center point of support wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com