Flexible packaging and method of manufacture

A technology of flexible film and flexible container, which is applied to the device for controlling tearing and opening, and the field of manufacturing flexible packaging components, which can solve the problems of increasing the demand for manufacturing materials and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

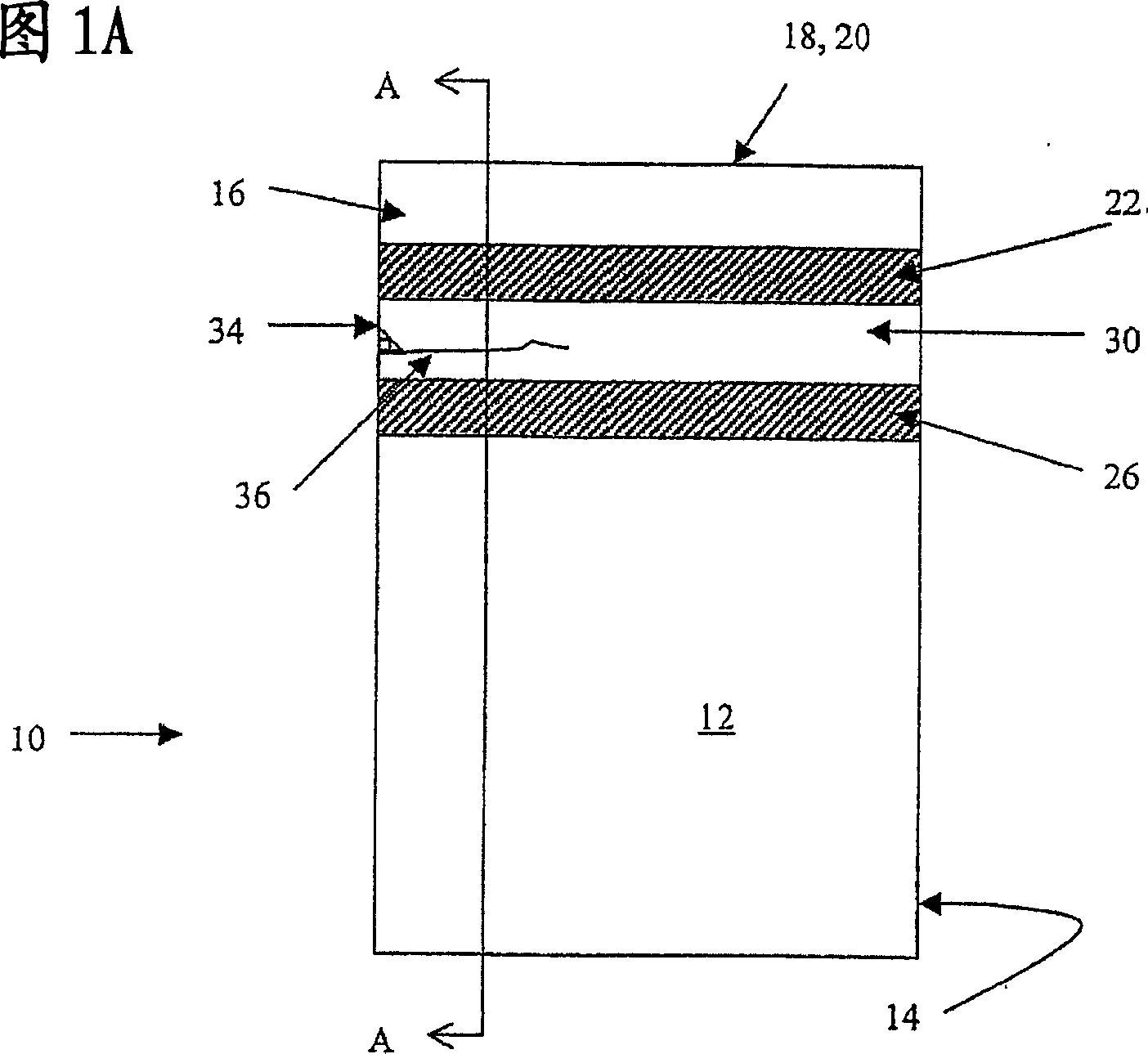

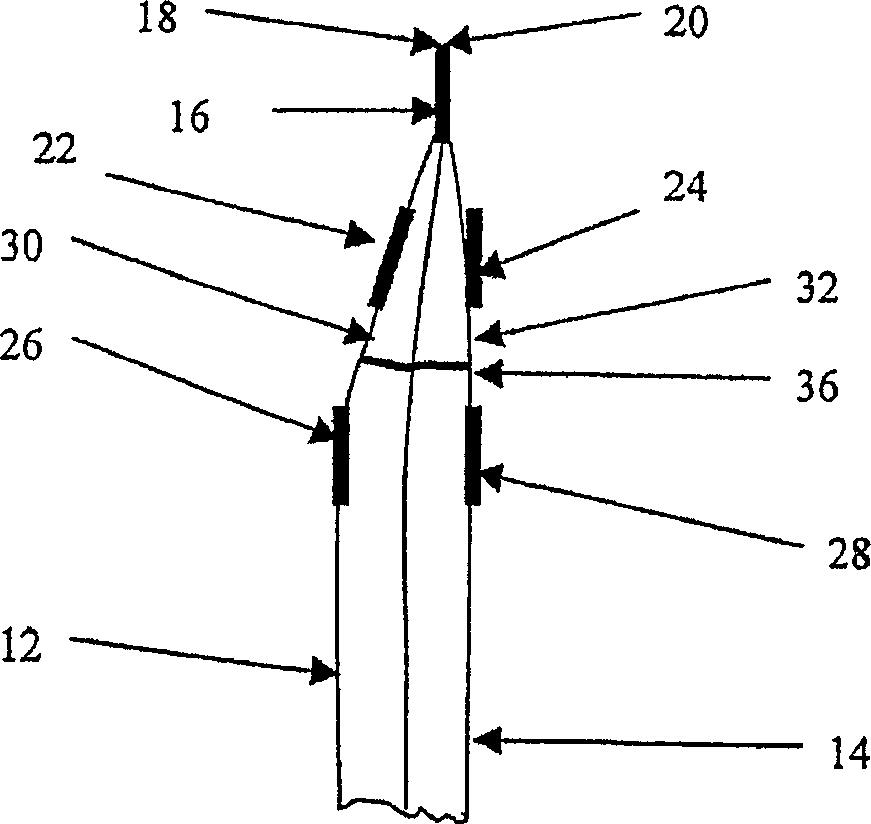

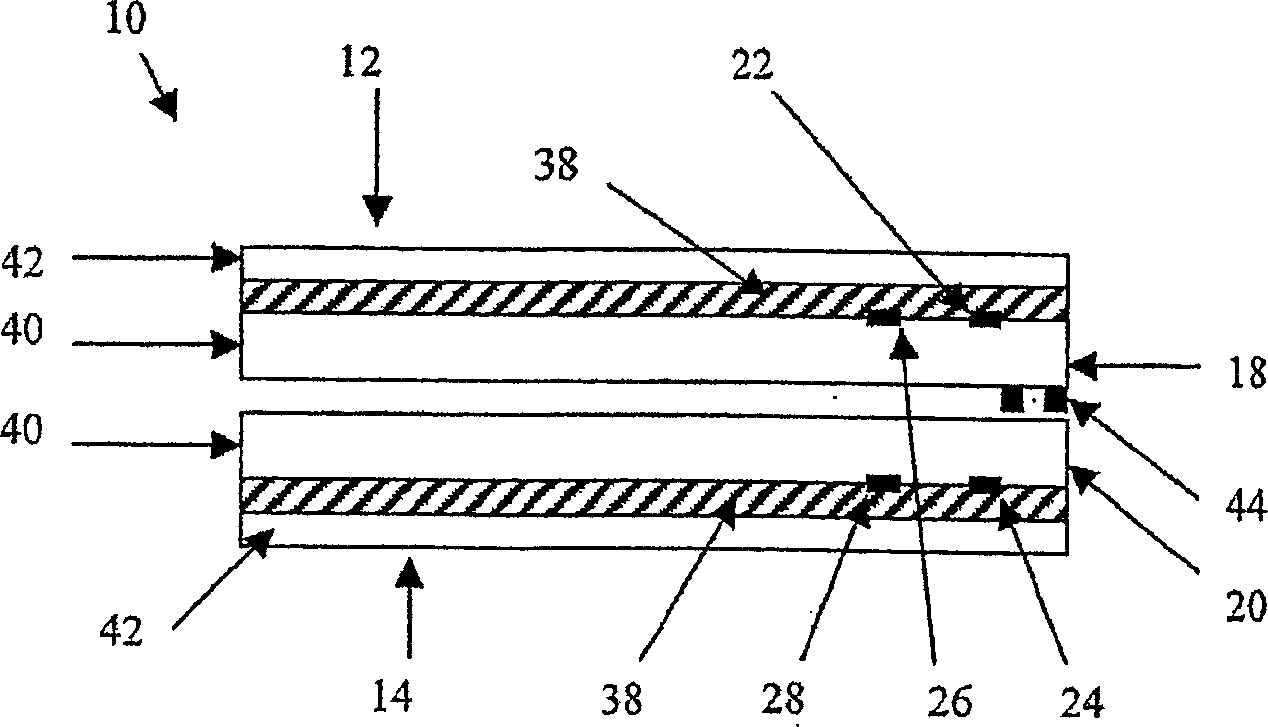

[0028] The present invention provides the definition of substantially coincident tear paths on opposing walls of a flexible packaging assembly made from a tearable film, such as a plastic film or a laminated film. The tear line facilitates controlled opening of the container by consumers wishing to access / obtain the contents of the container. By limiting the expansion of the opening slit to a defined path, a neat opening is obtained and the possibility of spillage, waste and mess is reduced. Such packaging components may be pouch containers, bags or the like.

[0029] The tearing path is defined by affixing tear-limiting elements in the form of pairs of barrier strips to the surface of the container wall or to the plies of material in the laminate constituting the wall. Preferably said strips are substantially parallel to each other. The barrier strips can be attached to the outer or inner surface of the container and in any combination. In a preferred embodiment, said stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com