Apparatus for automatic drawing out of cotton swab

A technology for extracting device and cotton swab, which is applied in the field of extracting device for cotton swabs, which can solve problems affecting the hygiene of cotton swabs, waste of cotton swabs, contact pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

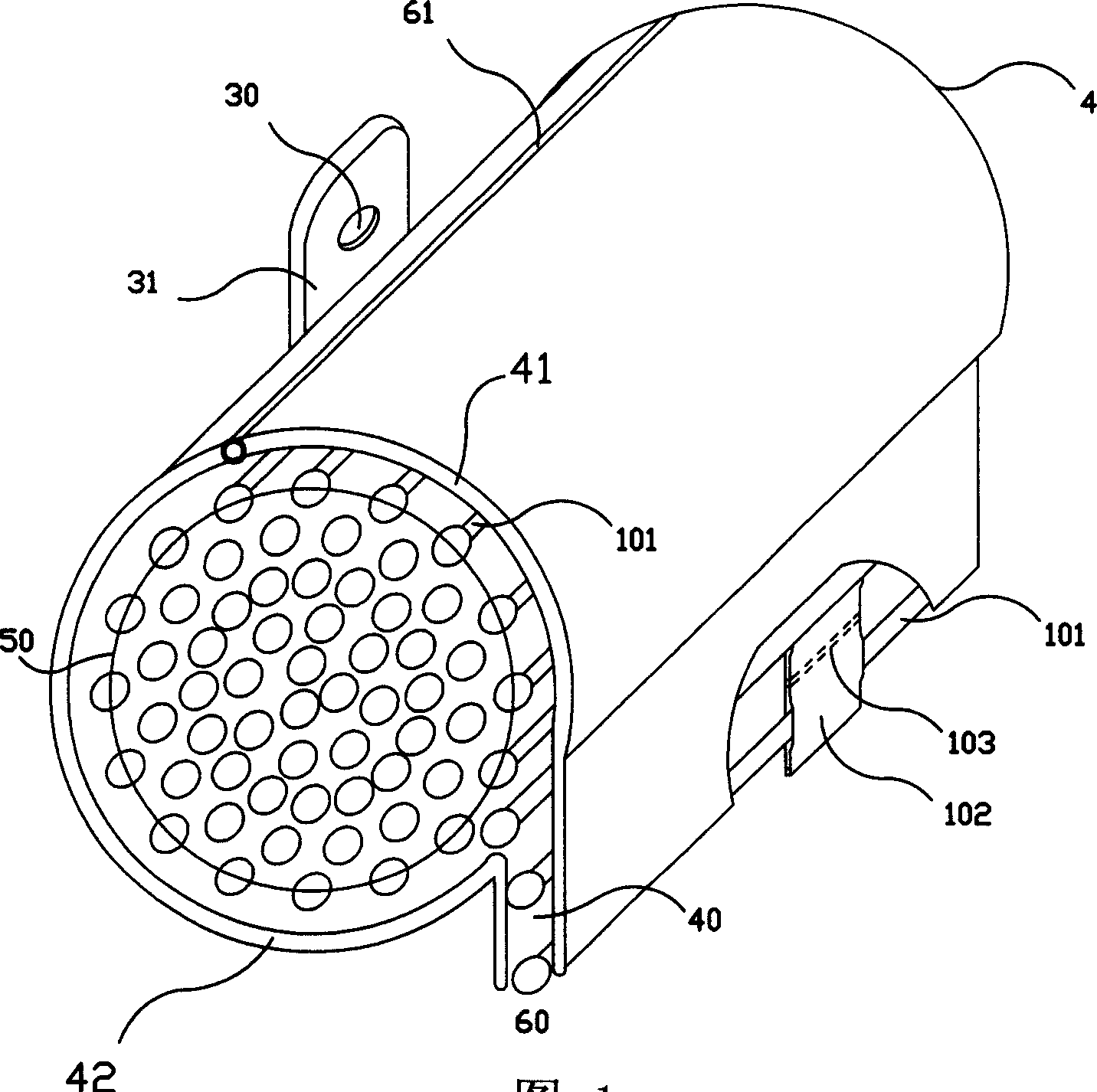

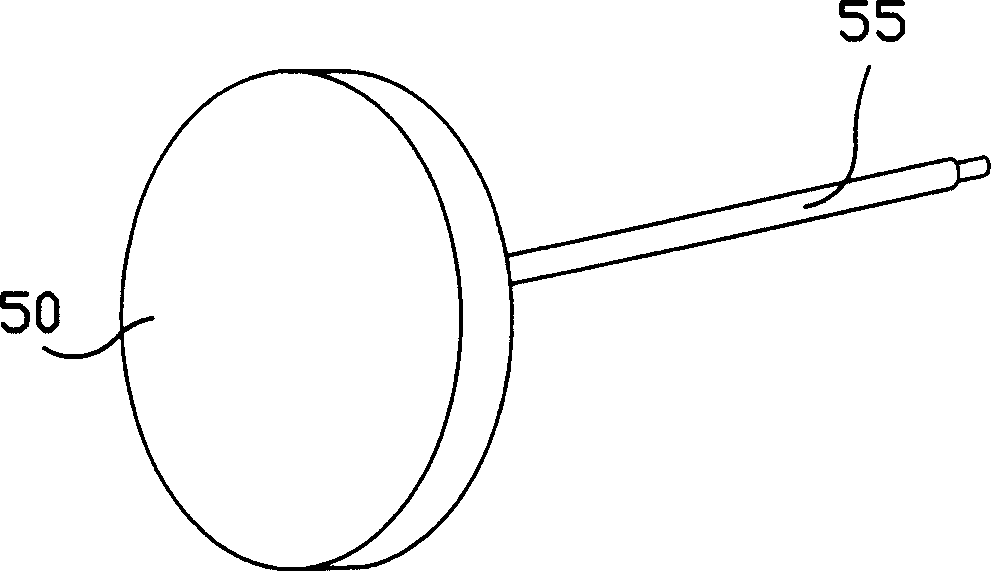

[0022] Example 1, see attached figure 1 To attach figure 2 , an automatic extraction device for cotton swabs. The entire extraction device is designed in a cylindrical shape and includes a box body 4 for holding cotton swabs 101. The box body 4 is composed of two parts, a front box body 41 and a rear box body 42. , There is a gap at the closing place of the two box bodies, and this gap is the cotton swab outlet 40. The box body 4 is provided with a rotating body. The rotating body includes a turntable 50 positioned in the box body 4 and a rotating shaft 55 arranged at the center of the turntable 50. The cotton swabs 101 are arranged at a certain distance and connected in a strip shape, and one end of the strip cotton swab is wound On the rotating shaft 55 , the strip-shaped cotton swab is rolled into a cotton swab roll, and the whole cotton swab roll is supported on the turntable 50 , and the other end of the strip-shaped cotton swab is drawn out from the cotton swab outlet ...

example 2

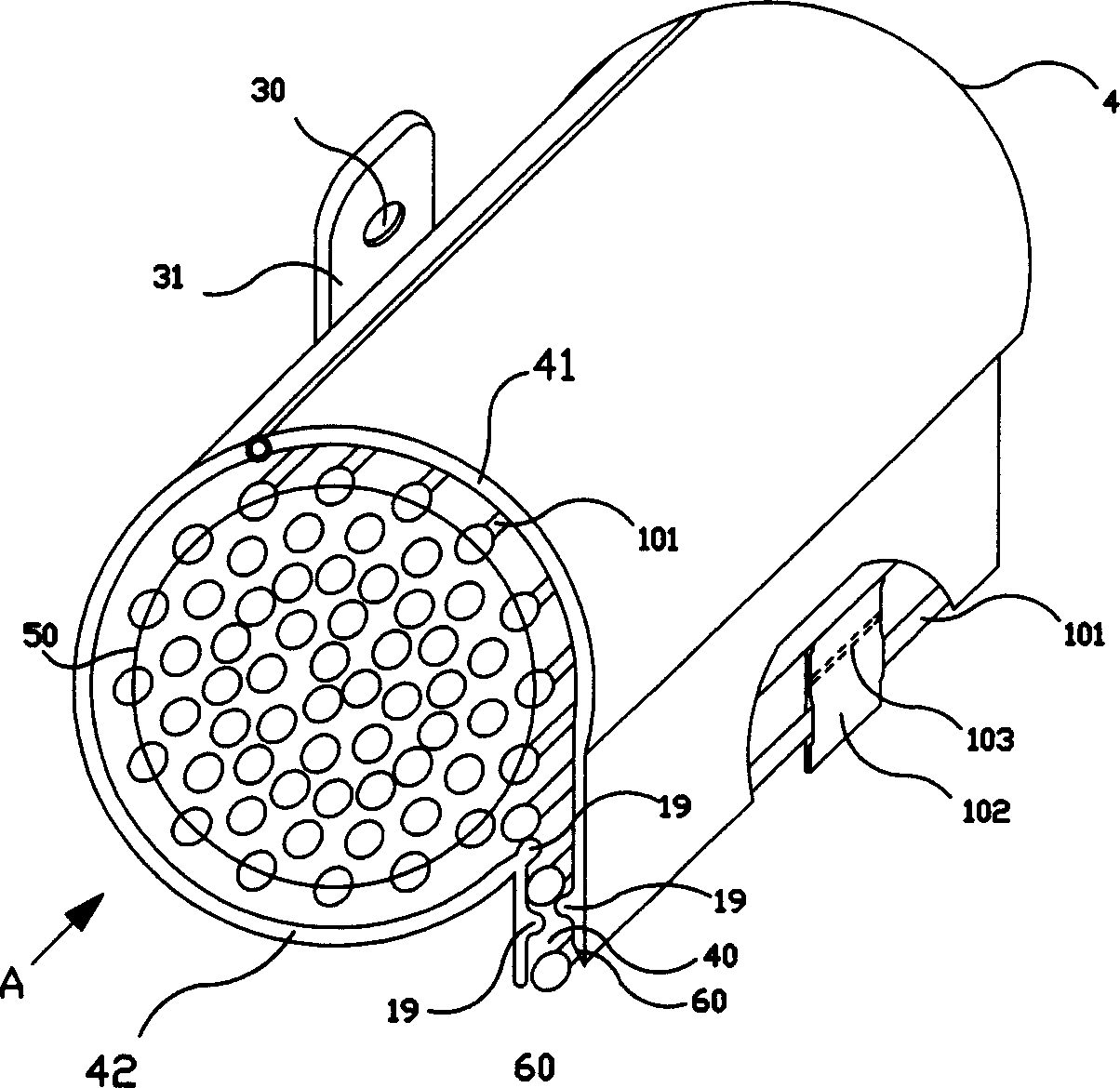

[0025] Example 2, see attached figure 2 To attach Figure 4 , on the basis of Embodiment 1, some designs are added, that is, at the cotton swab outlet 40 of the box body 4, a locking device for holding the cotton swab 101 and making the cotton swab 101 be extracted one by one is provided. The front box body and the rear box body of the outlet 40 are provided with three snap-in frames 19 with strip-shaped flanges, and a knife edge 60 is arranged on one side outside the snap-in device.

[0026] When the cotton swabs are pulled out, the cotton swabs 101 fall one by one between the three snap-in frames 19 with strip-shaped flanges, so that the cotton swabs will not be pulled out in a row, but pulled out one by one according to the needs. When pulling out, the set When the cutting line 103 is broken on the cotton swab connection belt 102, the cotton swabs can be separated individually. At the same time, the position of the whole cotton swabs is moved down in order to realize the ...

example 3

[0027] Example 3, see attached Figure 5 To attach Figure 7 , on the basis of embodiment 2, some designs are added, and the upper box body of the box body 4 is provided with a bracket groove 1, and the bracket groove 1 is connected with the turntable. The end 22 of the rotating shaft 55 is stuck on the bottom 16 of the bracket groove 1, so that the entire turntable 50 is not easy to disengage and rise. One more design is provided so that the turntable can rotate freely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com