Passive differential calorimeter

A passive differential type, heat meter technology, applied in the direction of measuring heat, calorimeters, measuring devices, etc., can solve the problems of heating company losses, consuming manpower, material resources and financial resources of heating companies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

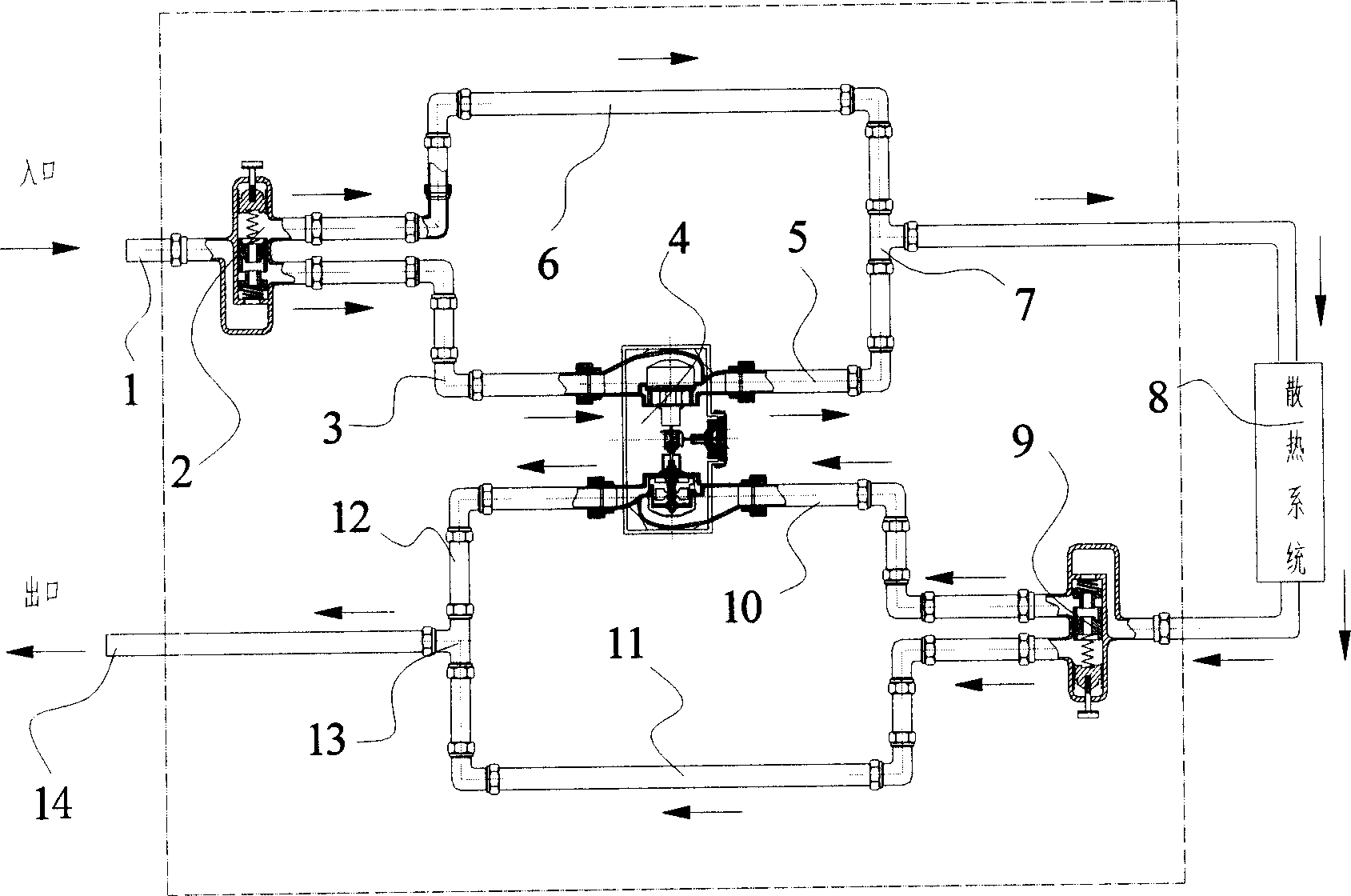

[0010] Combine below figure 1 The passive differential heat meter of the present invention is described in detail, figure 1 The double-dot dash line in the middle is the heat meter.

[0011] First of all, it should be noted that the medium in the passive differential heat meter of the present invention can be any suitable fluid or semi-fluid, but for ease of illustration, water is used as an example below, but the medium used in the present invention is not Confined to water.

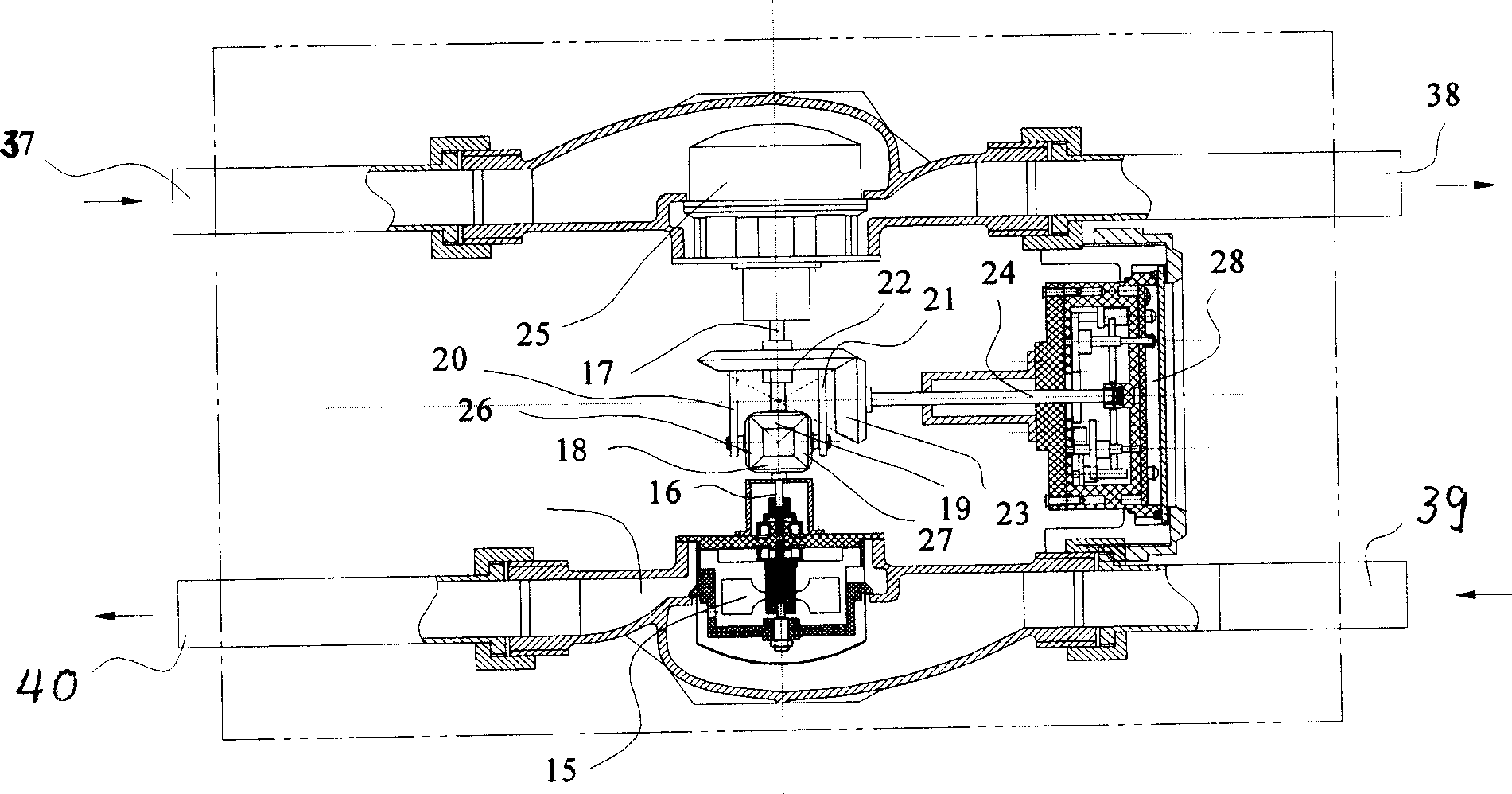

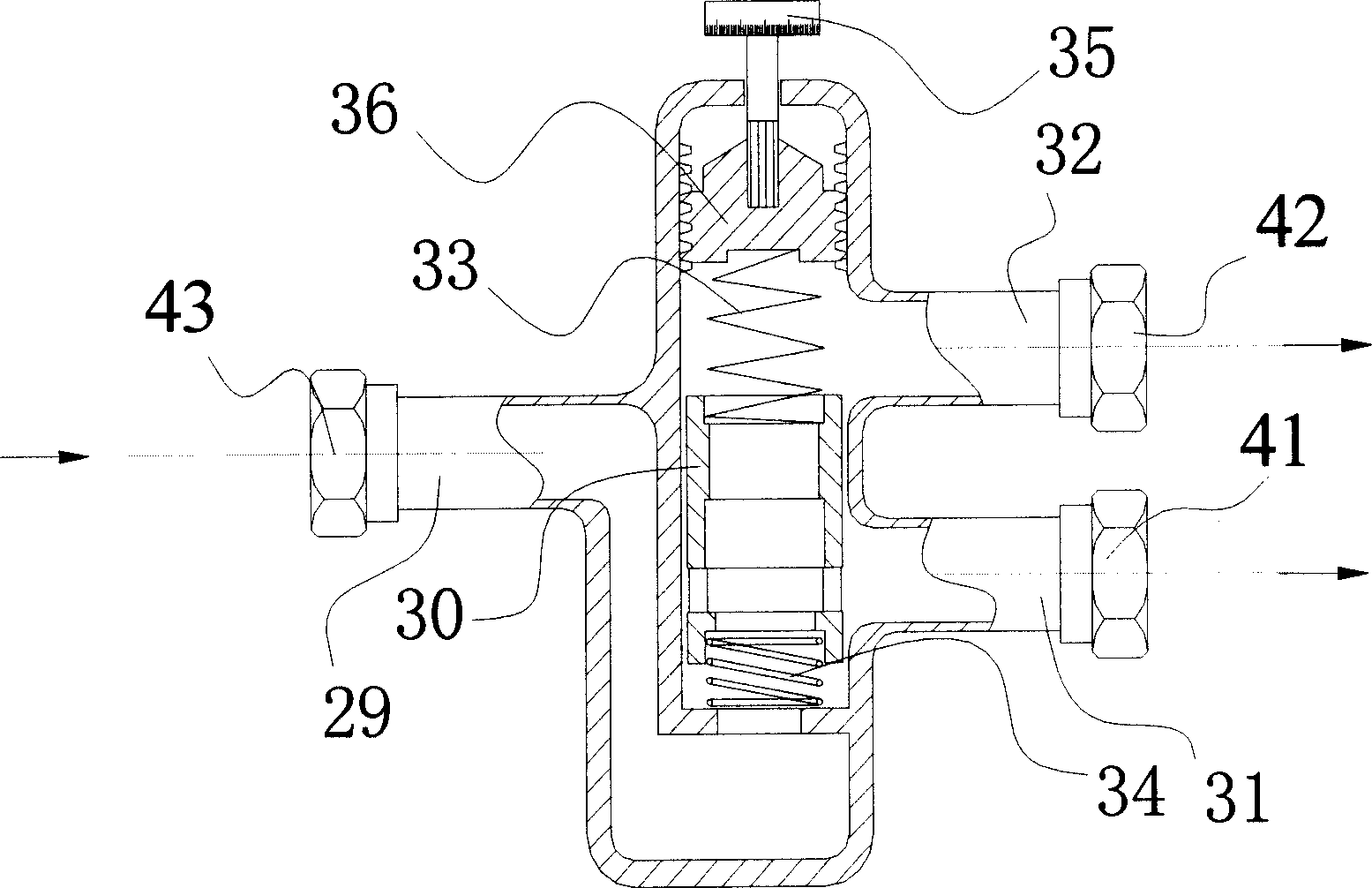

[0012] Such as figure 1 As shown in, the passive differential heat meter of the present invention (hereinafter referred to as the heat meter) includes the water inlet flow distributor 2, the heat counter 4, the return water flow distributor 9 and the connecting pipes between them, the water inlet flow distributor 2 is connected to the inlet 1 of the heat meter, the outlet of the water inlet flow distributor 2 is connected to the water pipe 3 and the bypass water pipe 6 respectively, the water pipe 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com