Method for making film assy used in PDP filter, film assy manufactured by the method, and PDP filter with the film assy

A technology of membrane components and optical filters, applied in the manufacture of ships or lead wires, pipe structural parts, optical/shielding devices, etc., can solve the problems of reduced productivity and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

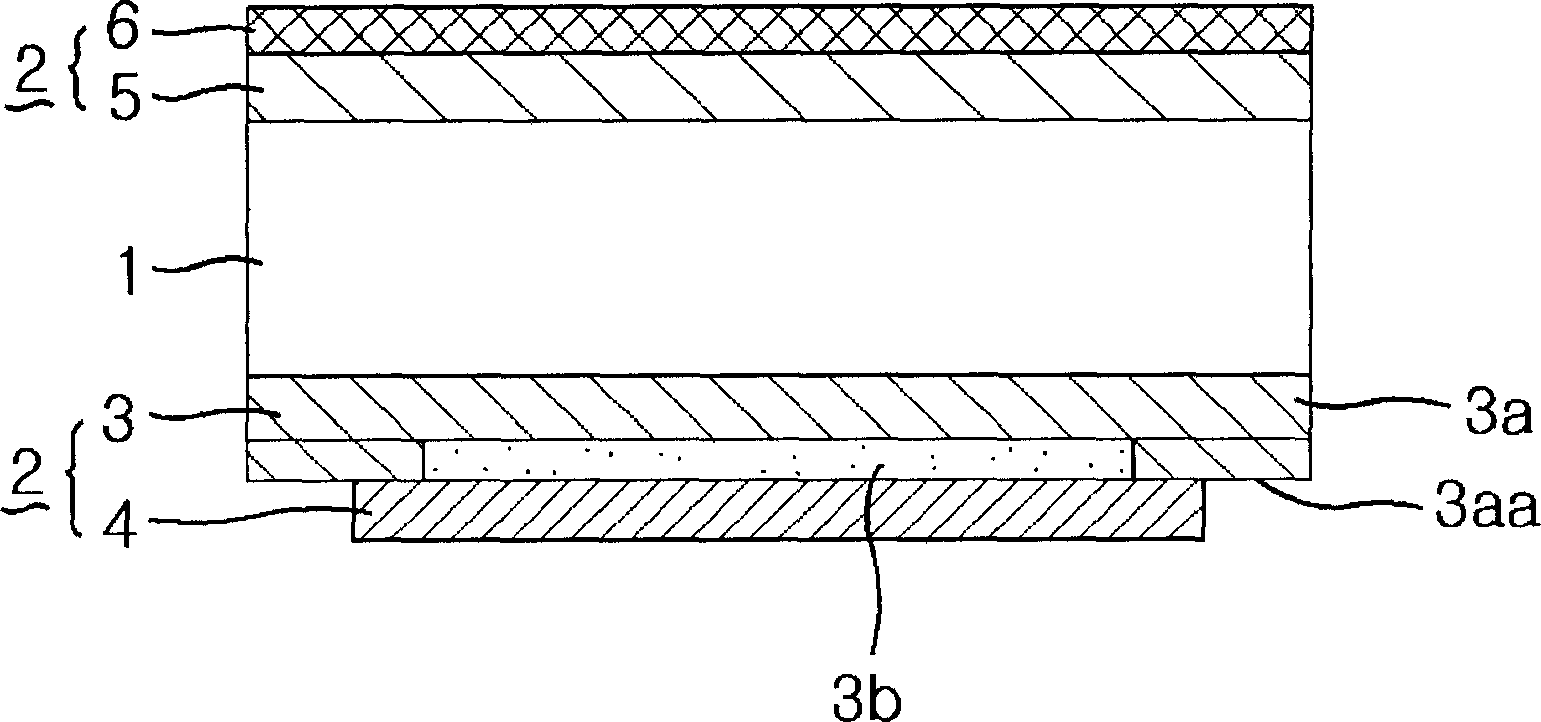

[0048] now refer to Figure 4-29 Embodiments of the present invention are described in detail.

[0049] Figure 4 showing the arrangement of a roll apparatus for preparing a film assembly of a PDP filter according to the present invention, and Figure 5 is a flowchart showing a method for preparing a membrane module of a PDP filter according to the first embodiment of the present invention;

[0050] now refer to Figure 5-9 A method of manufacturing the film module of the PDP filter according to the first embodiment of the present invention is described.

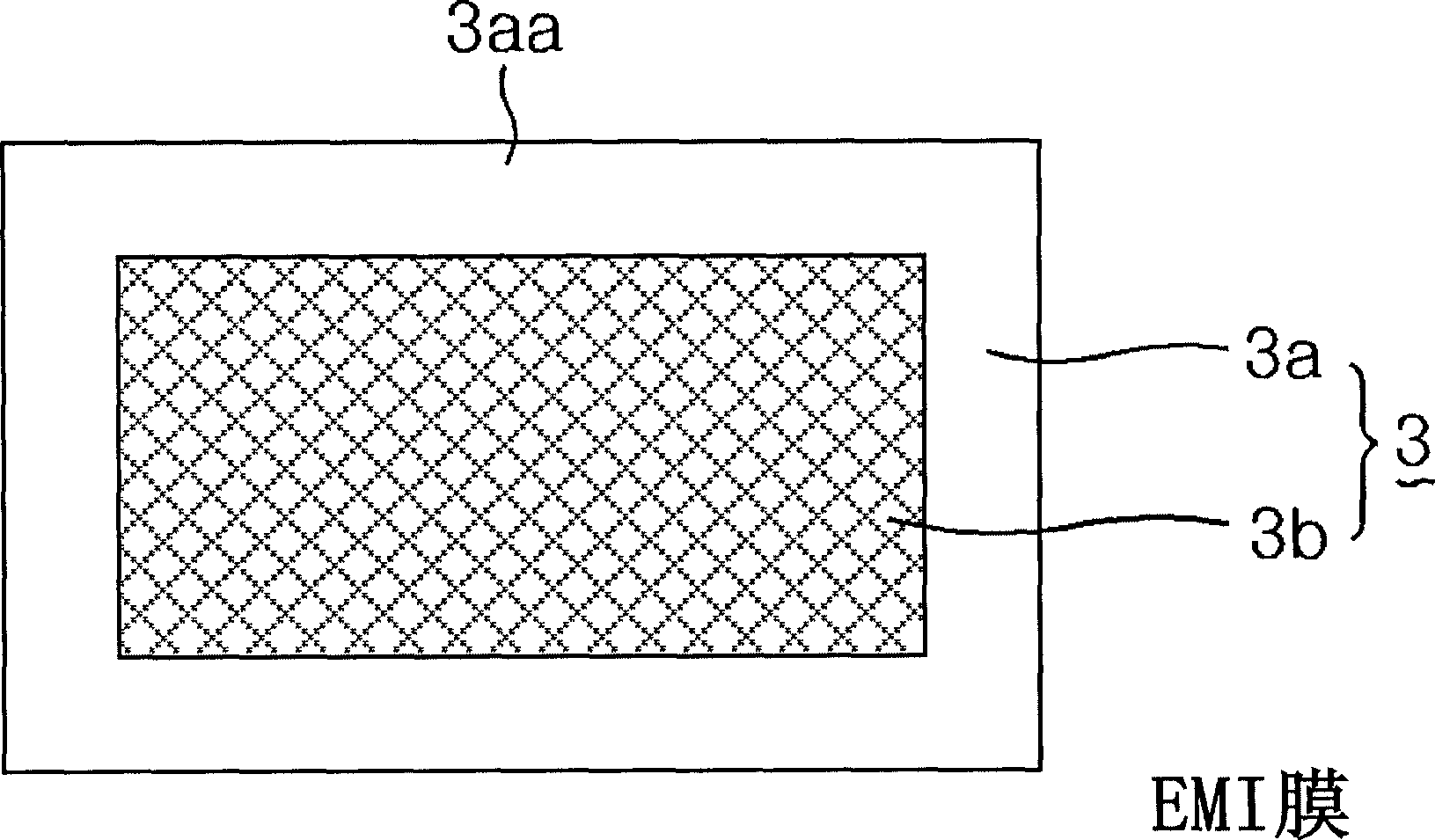

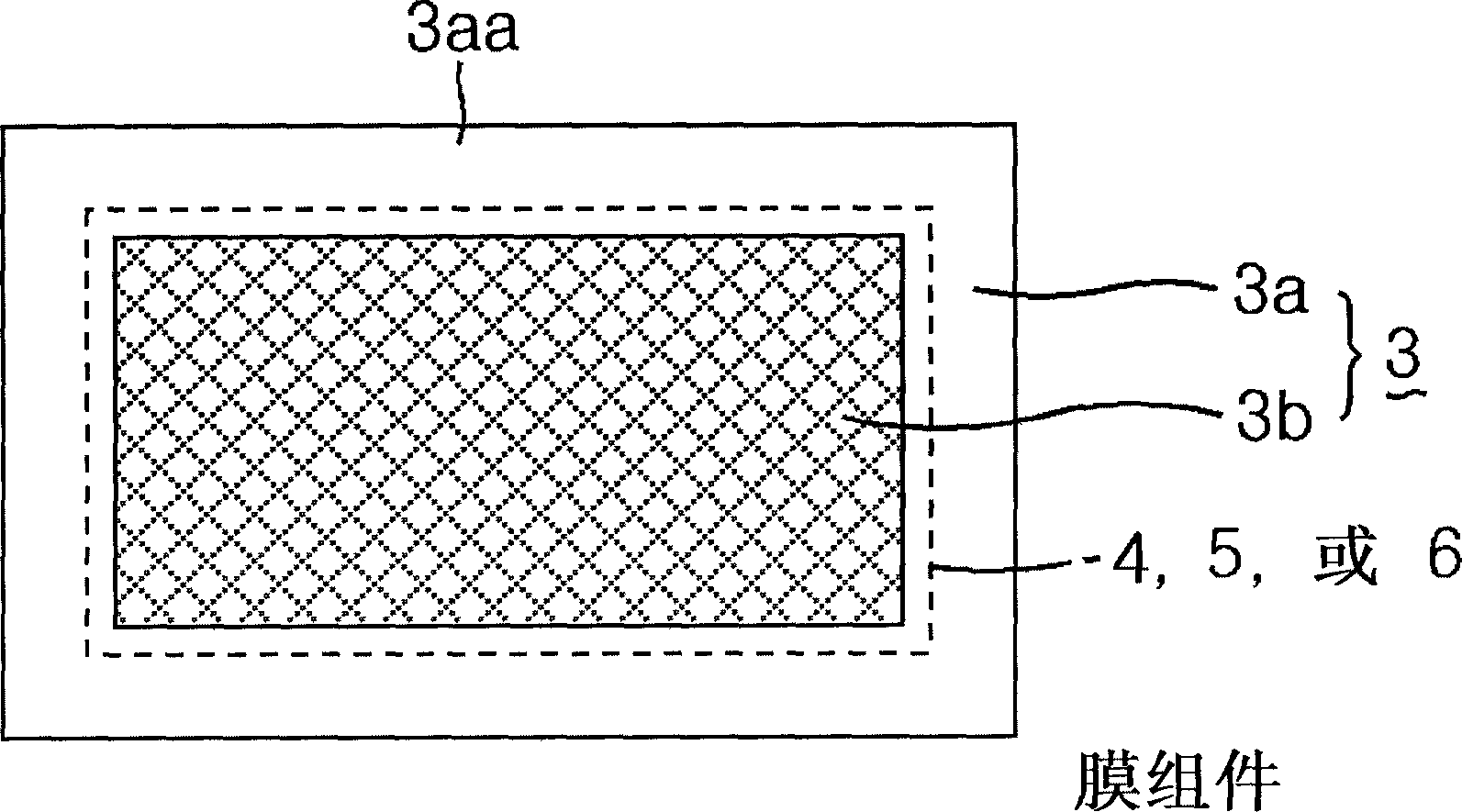

[0051] An EMI film 3 having a plurality of conductive effective screen portions 3b formed at predetermined intervals on the surface of a long transparent polymer resin film 3a is provided in a roll type. The roll of EMI film is then mounted on the first feed roll 7 (step 500).

[0052] Then, at least one long transparent functional film 4, 5 and 6 capable of at least partially covering the effective screen portion 3b of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com