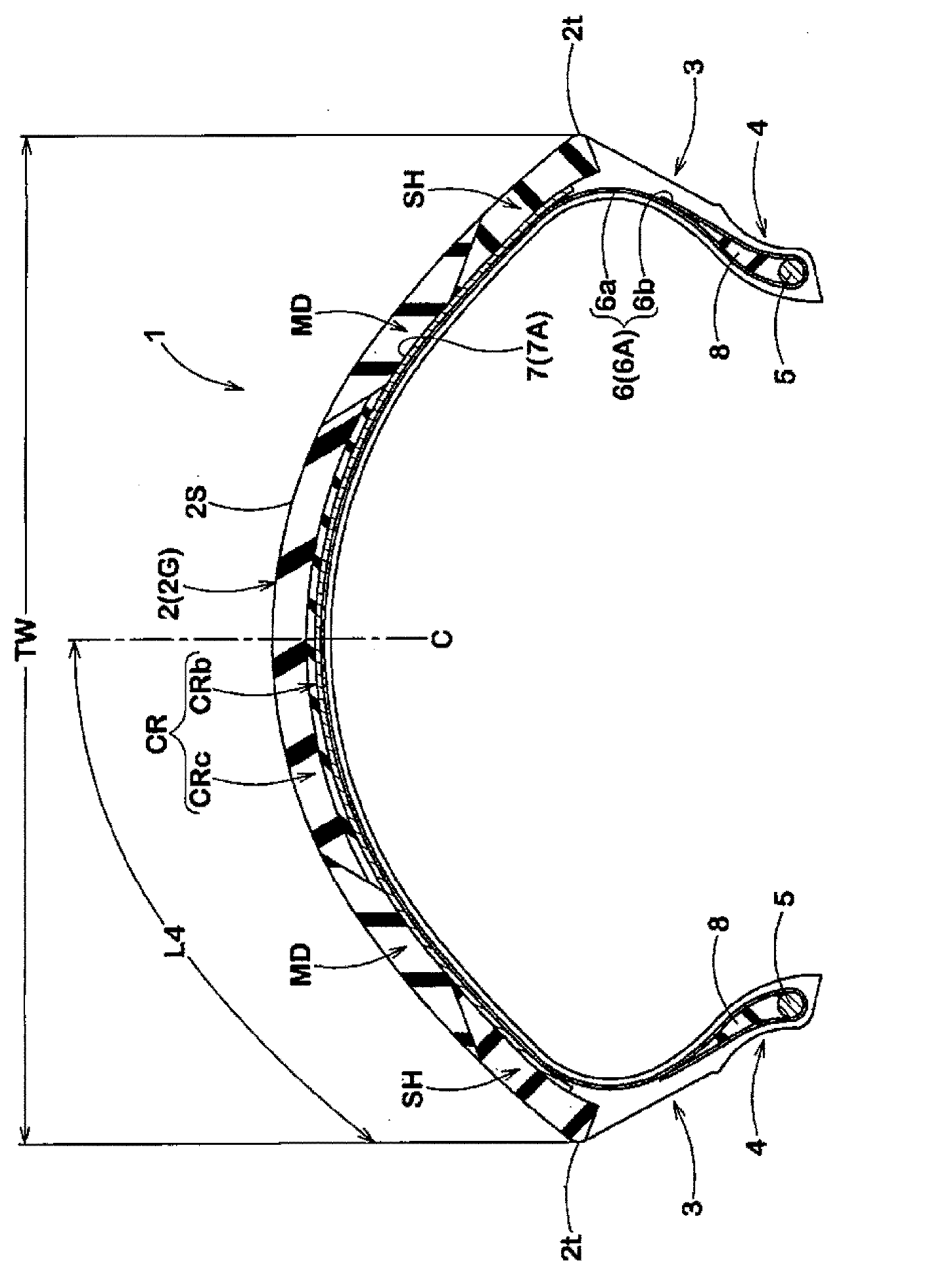

Two-wheeled automotive vehicle tire

A technology for motorcycles and tires, applied to motorcycle tires, motorcycles, tire parts, etc., can solve the problems of reduced turning performance and inability to exert grip, so as to improve turning performance, suppress spongy thermal damage, and improve Effect of Rolling Resistance Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

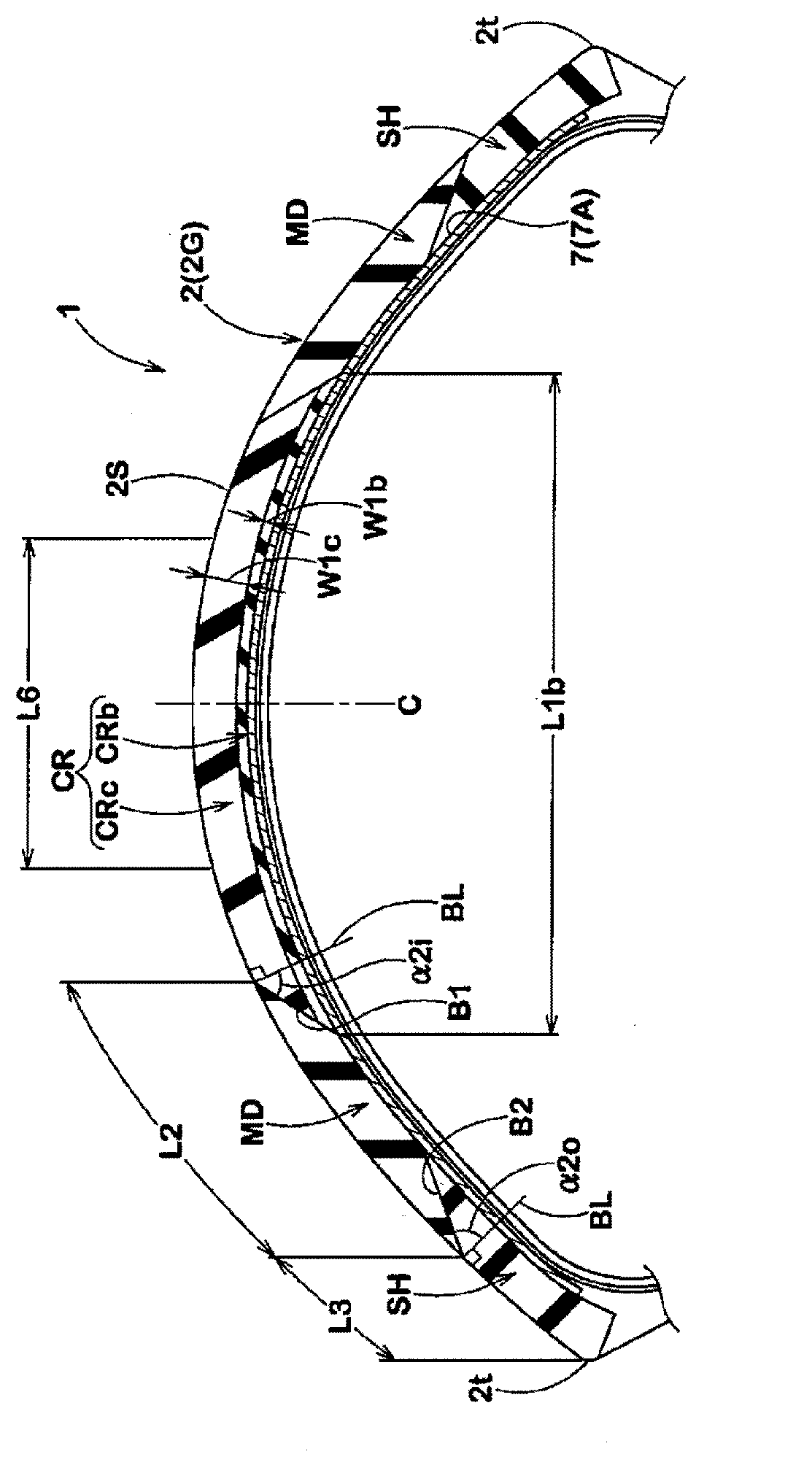

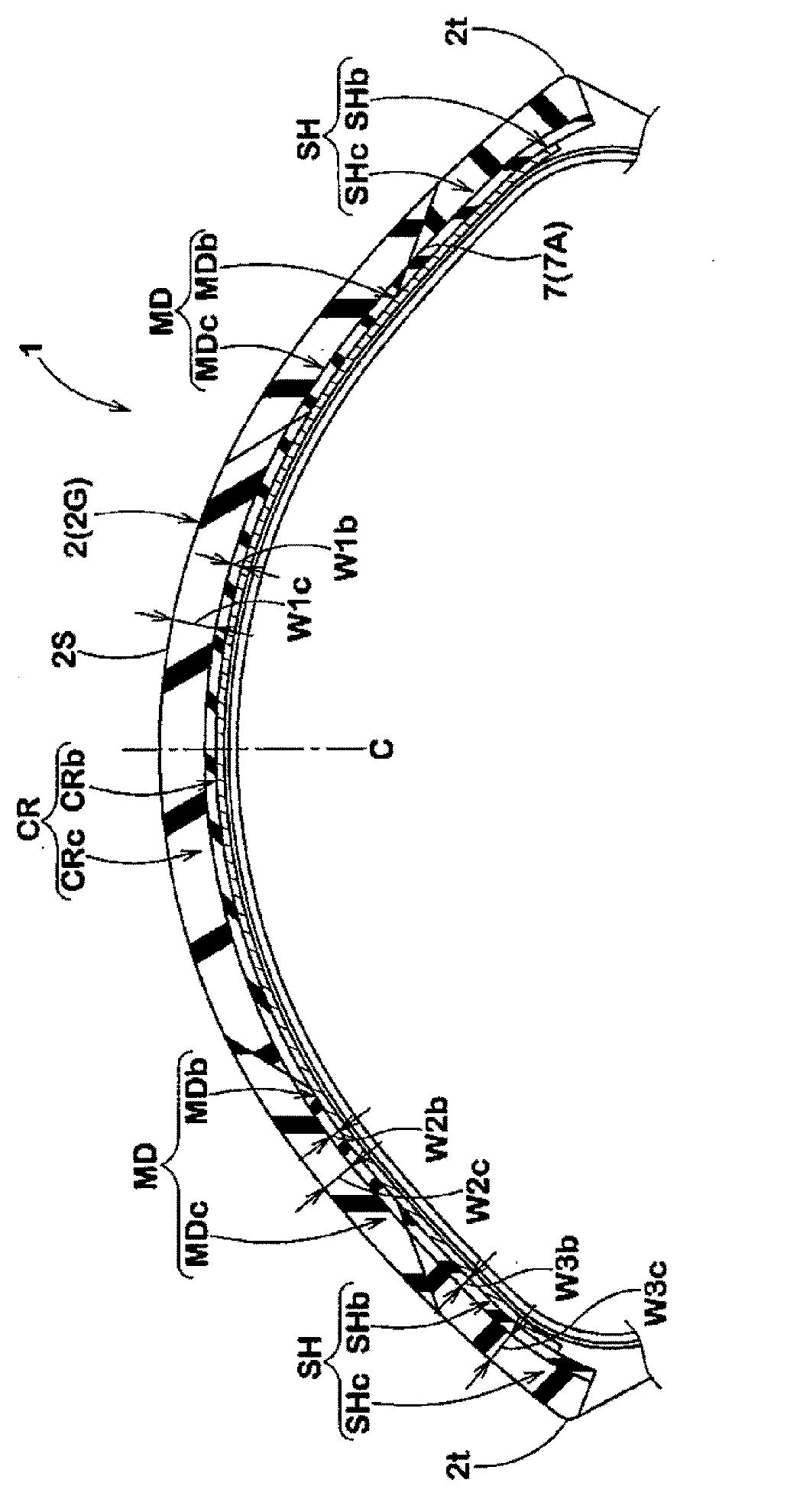

[0168] manufactured with Figure 4 The basic structure of the motorcycle tires and the intermediate rubber of the specifications in Table 4 were tested, and their performance was tested. Furthermore, as a comparison, the Figure 5 The existing tires shown were subjected to the same test.

[0169] The common specifications are the same as those of Example I except for the following items. In addition, the test method is also the same as that of Example I.

[0170] Length L2o of outer middle rubber MDo: 50mm

[0171] L2o / L4 ratio: 43.5%

[0172] Length L6 in the tire axial direction of the ground contact surface at the time of running straight: 42mm

[0173] Mates of the central basal layer: Mate 1

[0174] FITS OF THE CENTRAL TOP LAYER: FIT 2

[0175] Fit of shoulder rubber: Fit 4

[0176] The results of the tests are shown in Table 4.

[0177] Table 4

[0178]

[0179] As a result of the test, it was confirmed that the tires of the Examples can achieve a high level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com