Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of reducing snow removal performance, performance on ice, and performance on snow, and achieve large snow column shearing force, suppress air column resonance, and reduce pass-by noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

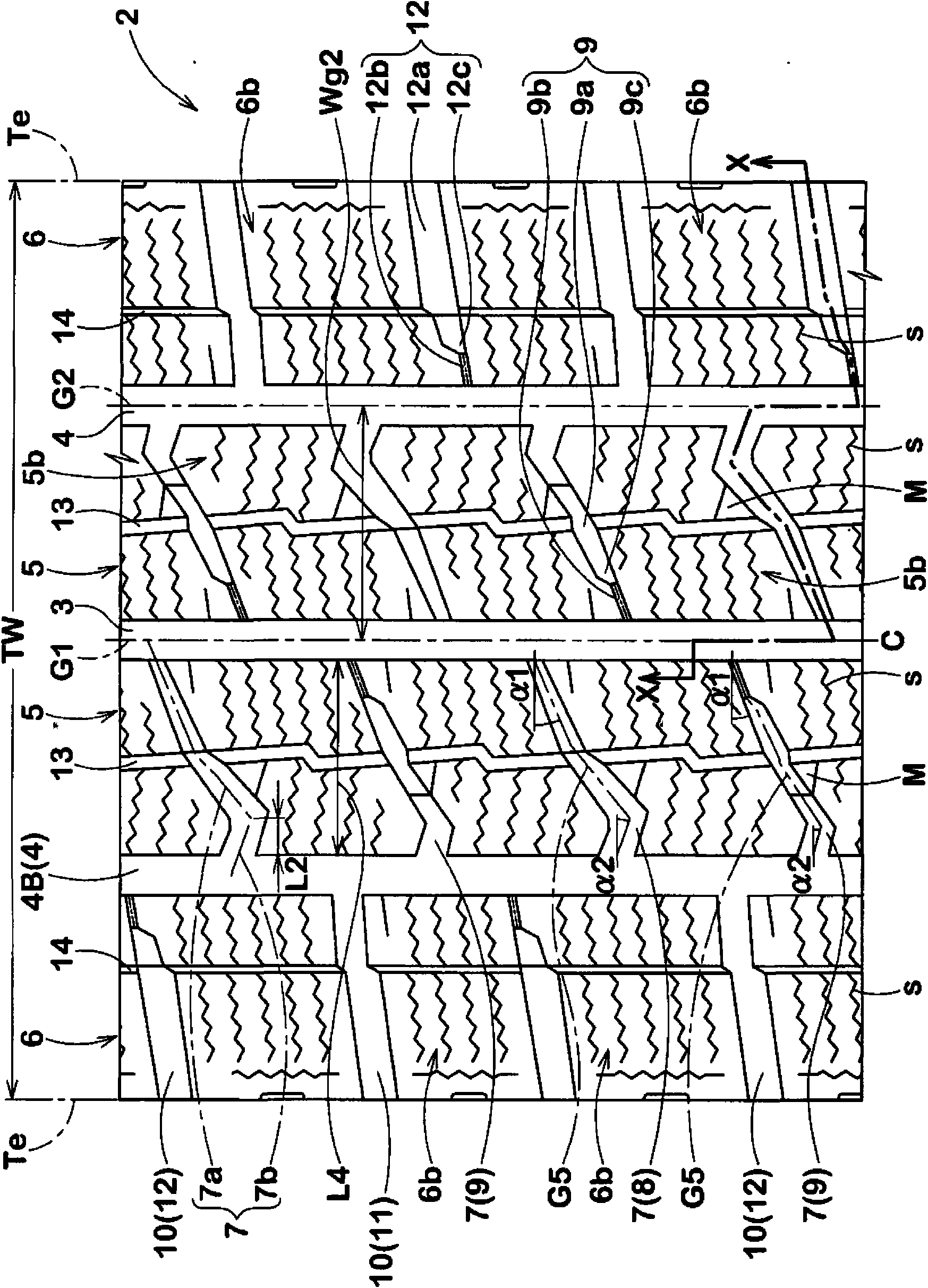

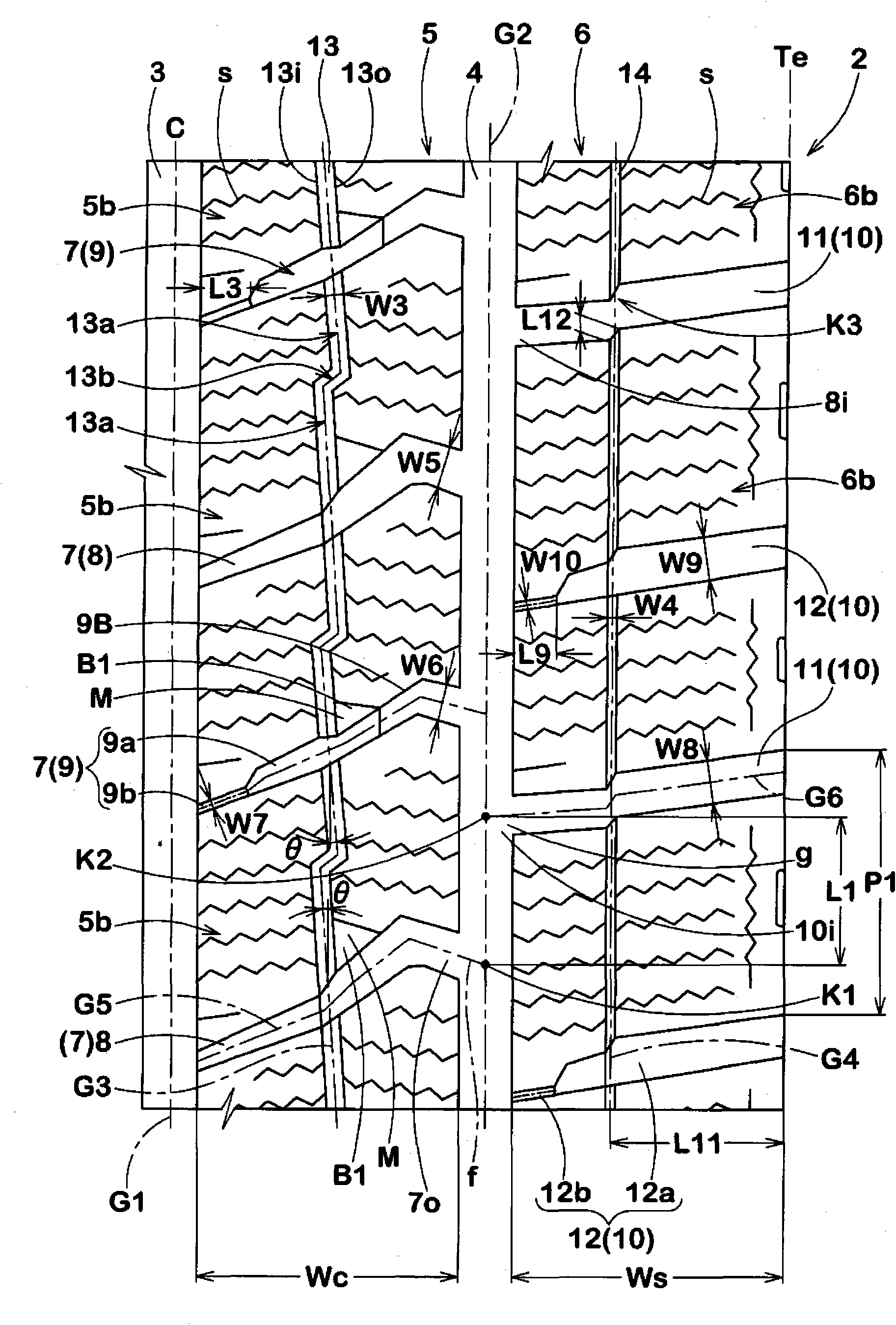

[0075] In order to confirm the effect of the present invention, a trial production with figure 1 195 / 65R15 non-studded tires for passenger cars with a pattern based on the specifications in Table 1. Moreover, each test tire was installed on an imported car with a displacement of 2000cc with a rim of 15×6.0J and an internal pressure of 200kPa, and the braking performance on snow, driving performance on ice, handling stability and passing noise were tested. In addition, it is the same except for the parameter shown in Table 1. In addition, common specifications are as follows.

[0076] Tread contact width TW: 166mm

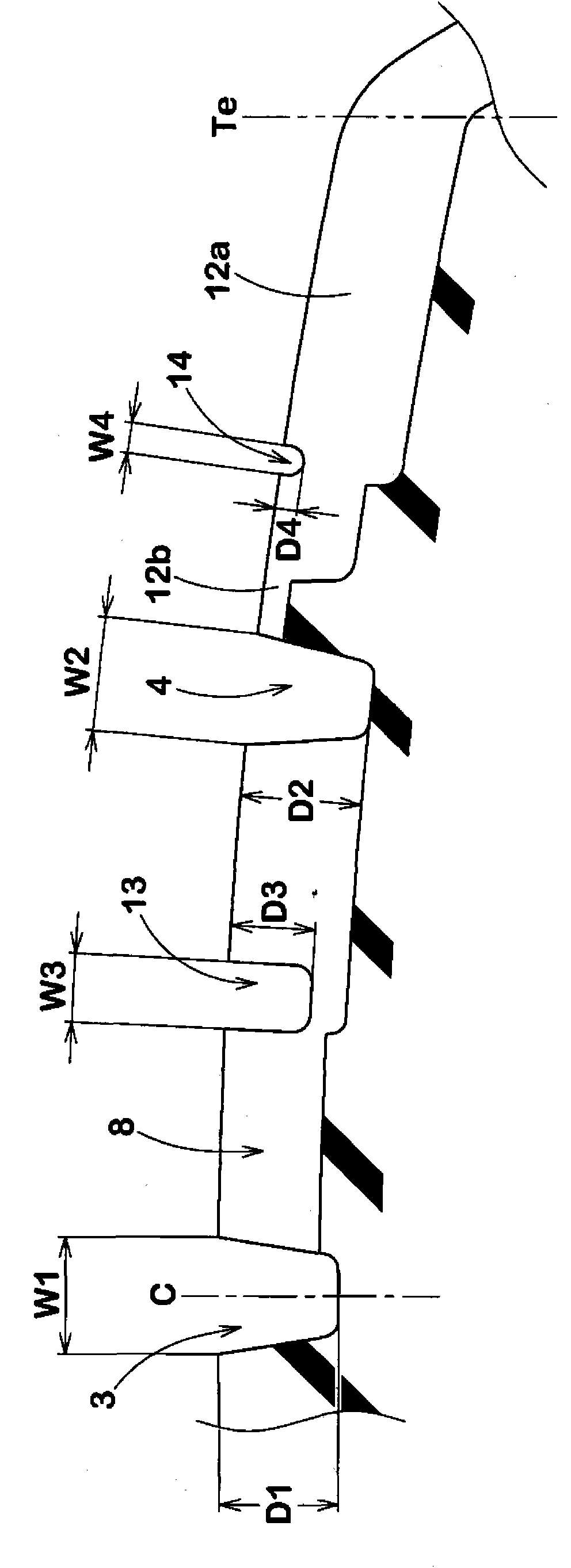

[0077] Groove width W1 of crown main groove: 7.2mm

[0078] Groove width W2 of shoulder main groove: 7.2mm

[0079] Configuration of shoulder main groove Wg2 / TW: 24%

[0080] Groove depth D1 of crown main groove: 9.1mm

[0081] Groove depth D2 of shoulder main groove: 9.1mm

[0082] Groove width W5 of the first crown transverse groove: change from 2.5 to 6.0m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com