Vacuum cleaner providing filter-absence detection

一种真空吸尘器、吸尘器的技术,应用在吸尘器、吸滤器、清洁设备等方向,能够解决吸尘器不能工作、阻碍脏物容器封闭、增加制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

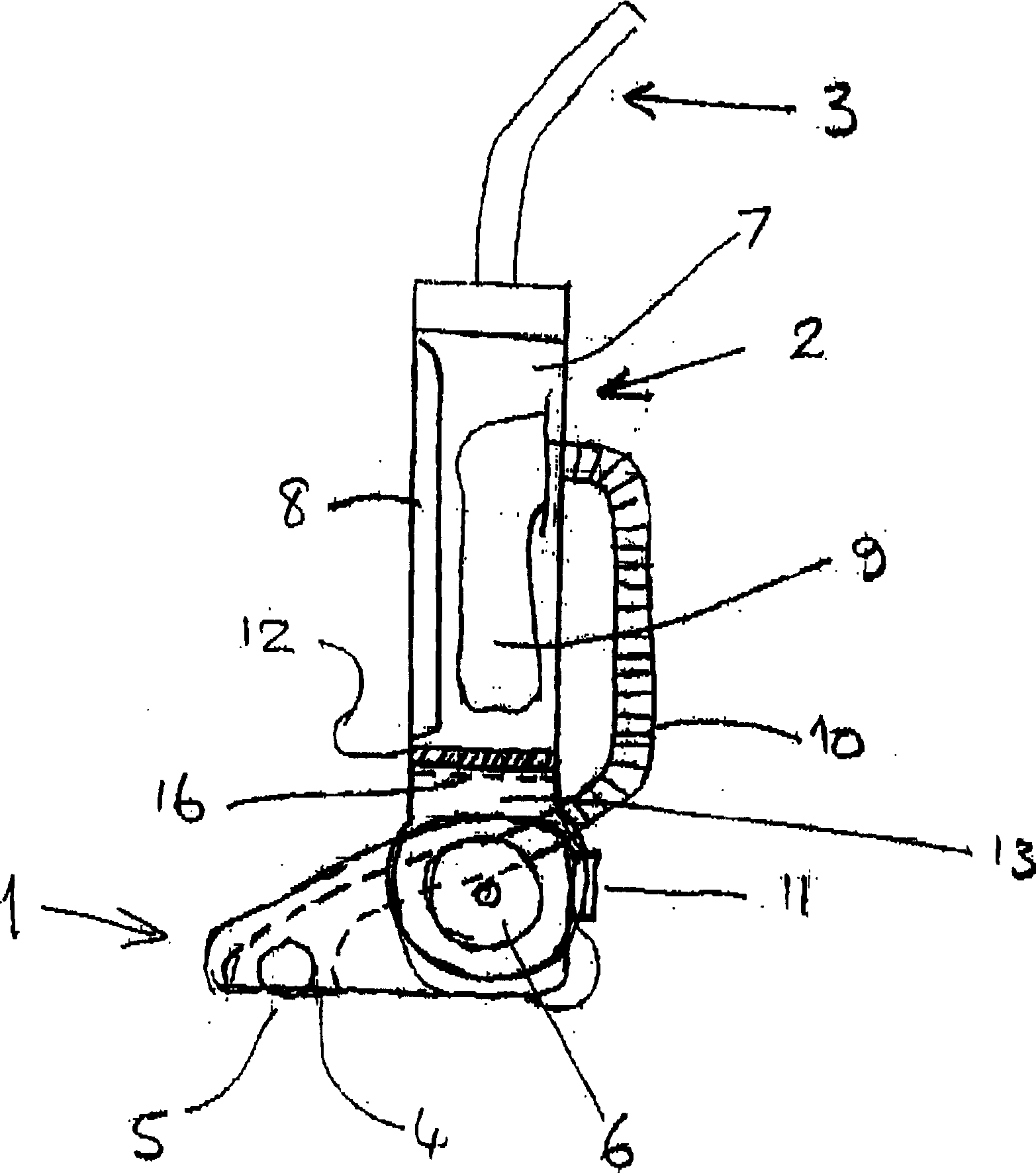

[0020] First refer to the attached figure 1 , shows a conventional upright type vacuum cleaner comprising a grounded foot or base unit 1 to which an upright body 2 is pivotally mounted. The grounding unit 1 is provided on its underside with a suction nozzle or inlet 4 in which a rotating brush 5 is arranged. The upright body 2 comprises a body divided into two chambers, namely a bag chamber 7 which is closed by a removable cover 8 and which in use houses a porous filter bag 9, and a motor chamber 13 which The motor / fan unit 6 is installed in the chamber 13 .

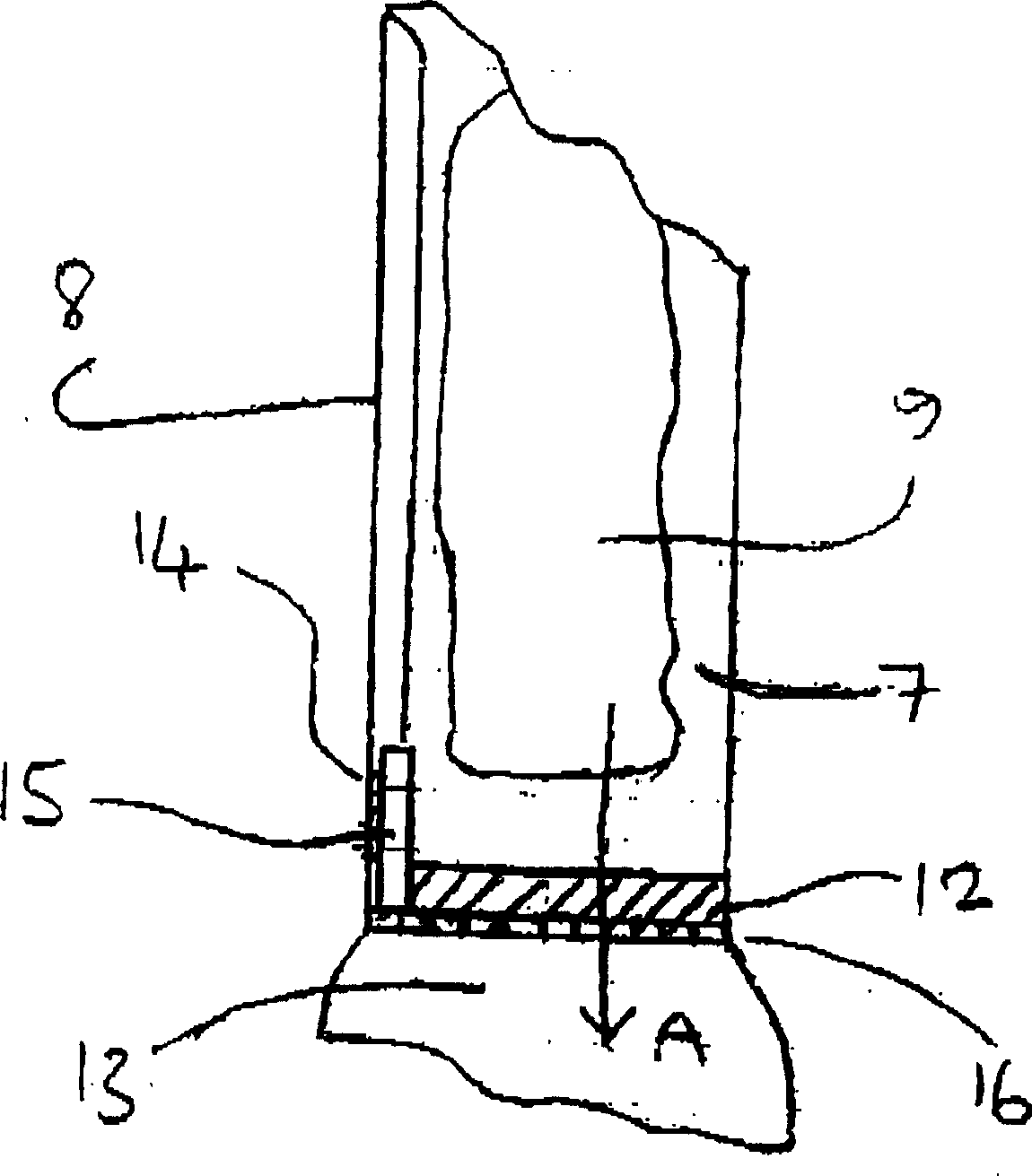

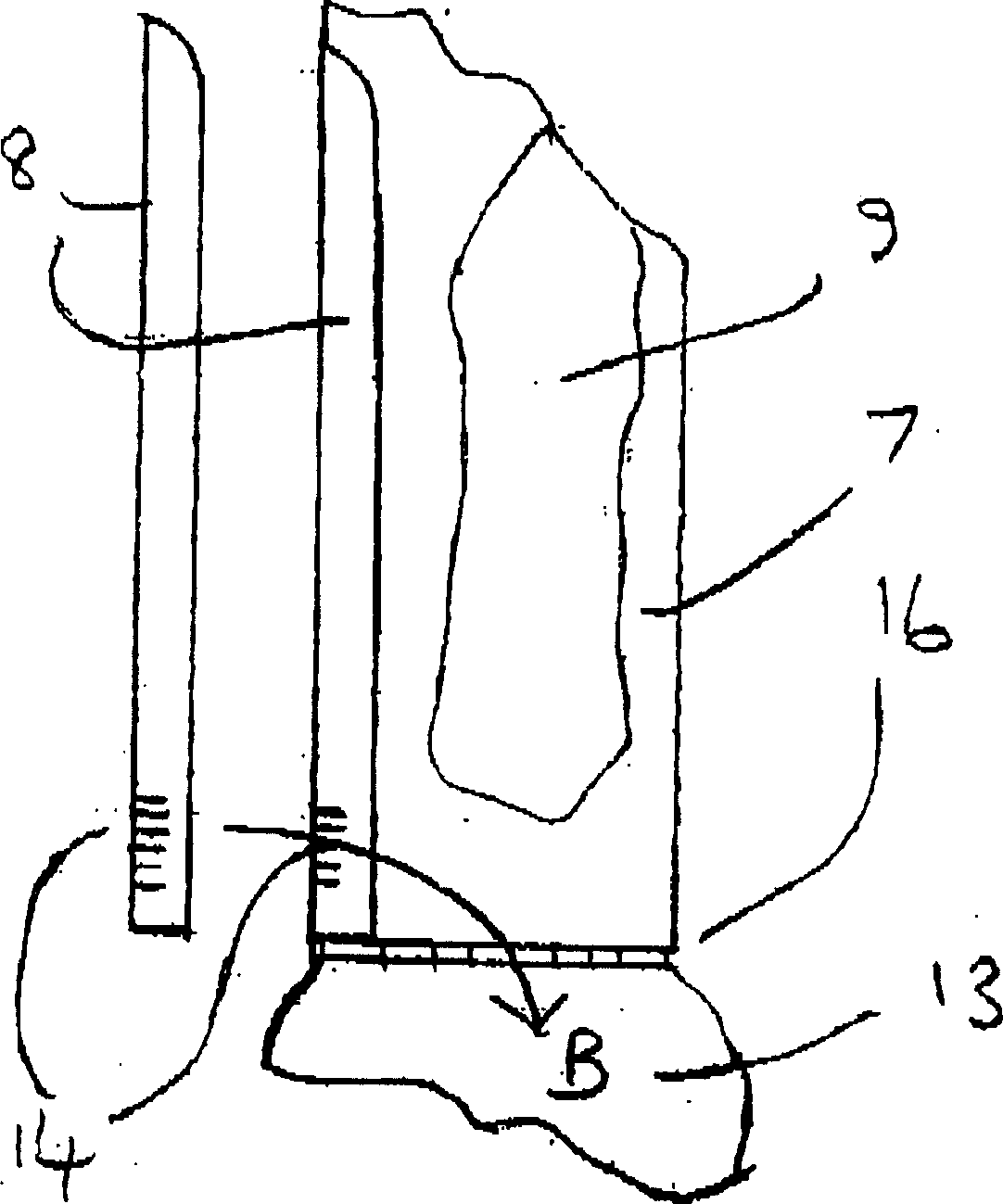

[0021] The motor chamber 13 is divided into two separate areas, one in fluid communication with the bag chamber 7 through the grille 16 and the other in fluid communication with the exhaust outlet 11 . A grid 16 comprising walls or partitions forming a series of openings, in the example shown, effectively forms the floor of the baghouse 7 and supports a filter element 12 arranged in the grid. The upper or upstream sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com