Push-button structure, push-button supporting structure and its producing method

A technology of supporting structure and manufacturing method, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of lower product qualification rate and higher production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

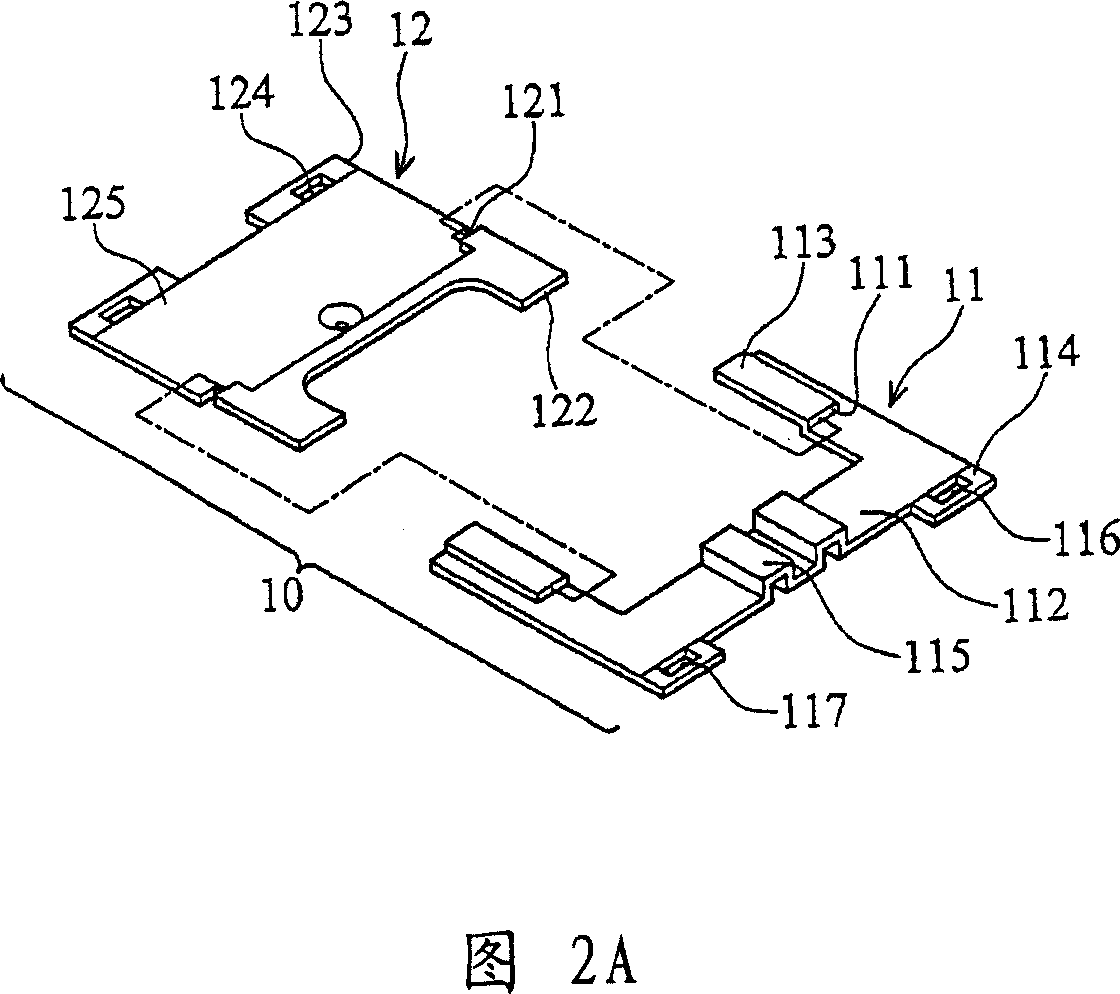

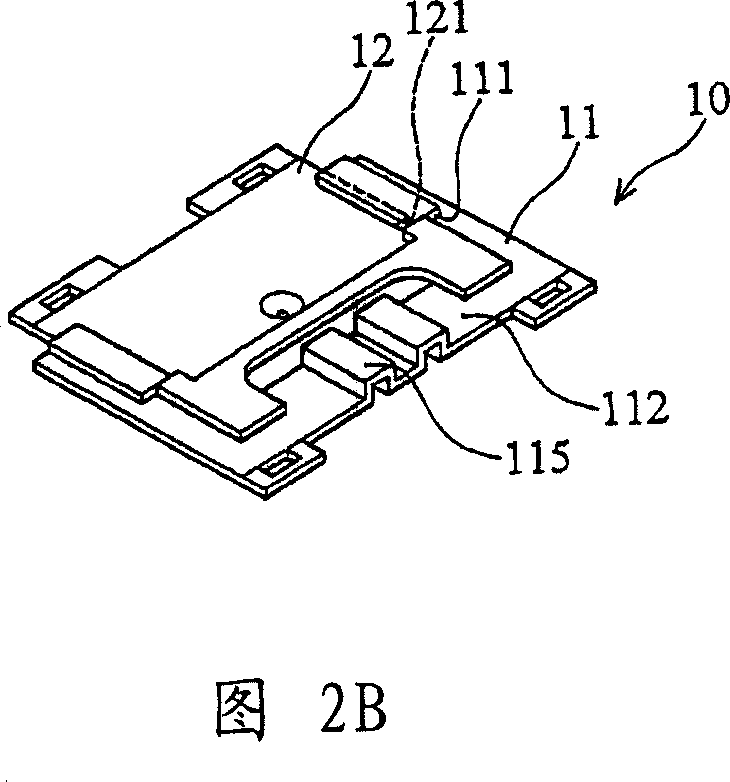

[0041] 2A, 2B, the key supporting structure 10 includes a first frame 11 and a second frame 12, the first frame 11 has a first combination part 111 and a cross bar 112, the second frame 12 has a second combination part 121, the first The combination part 111 and the second combination part 121 are engaged with each other through the wrinkle deformation 115 generated by the cross bar 112 , and the first frame 11 can rotate relative to the second frame 12 . It should be noted that the first frame 11 and the second frame 12 of this embodiment are made of metal.

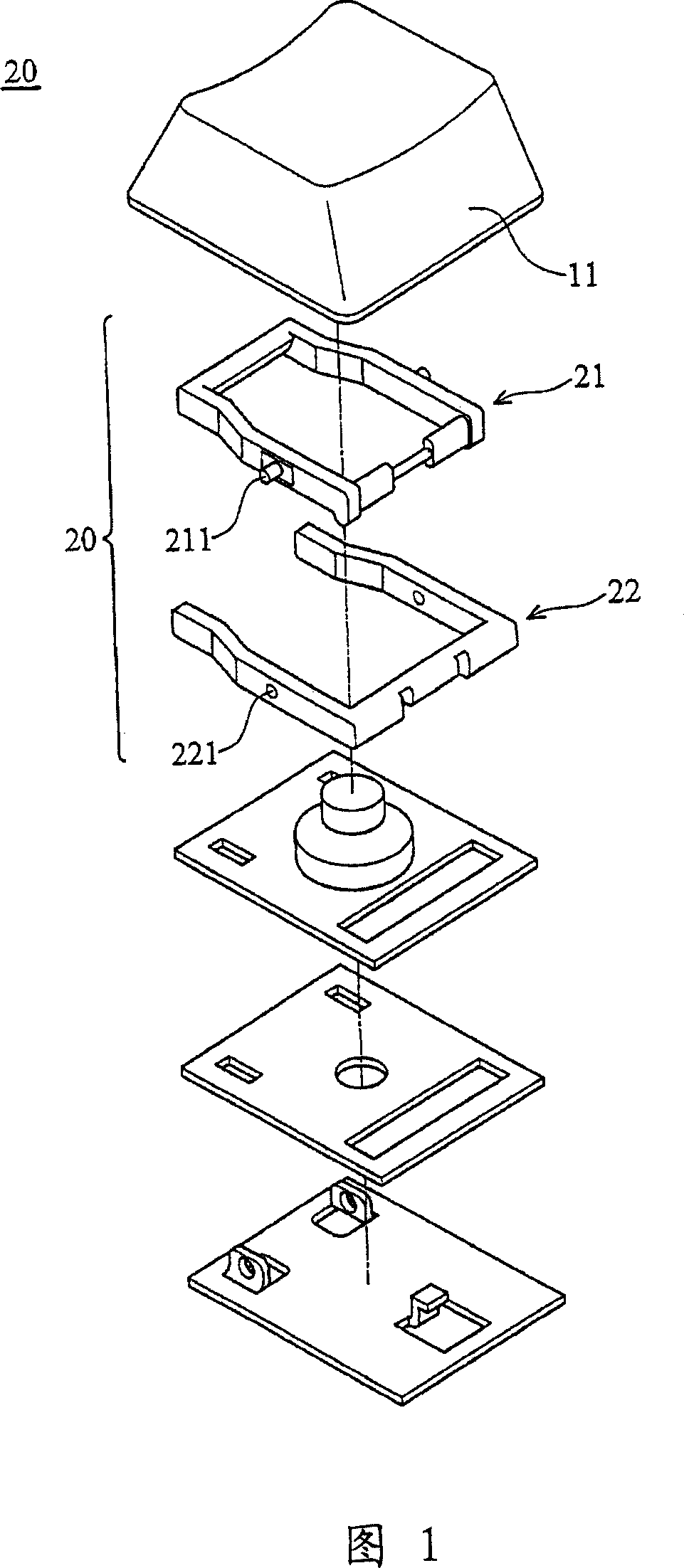

[0042] 3A, 3B, the button structure 30 of the present invention includes a keycap 31, a base 32 and the aforementioned support structure 10 (including the first frame 11 and the second frame 12), wherein the base 32 also includes a first connecting portion 321 and the second connecting part 322, and the first frame 11 has a first end 113, a second end 114, a first combination part 111 and a cross bar 112, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com