Straight inserting opening counter lock

An open and balanced technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problem that the tumbler lock is easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

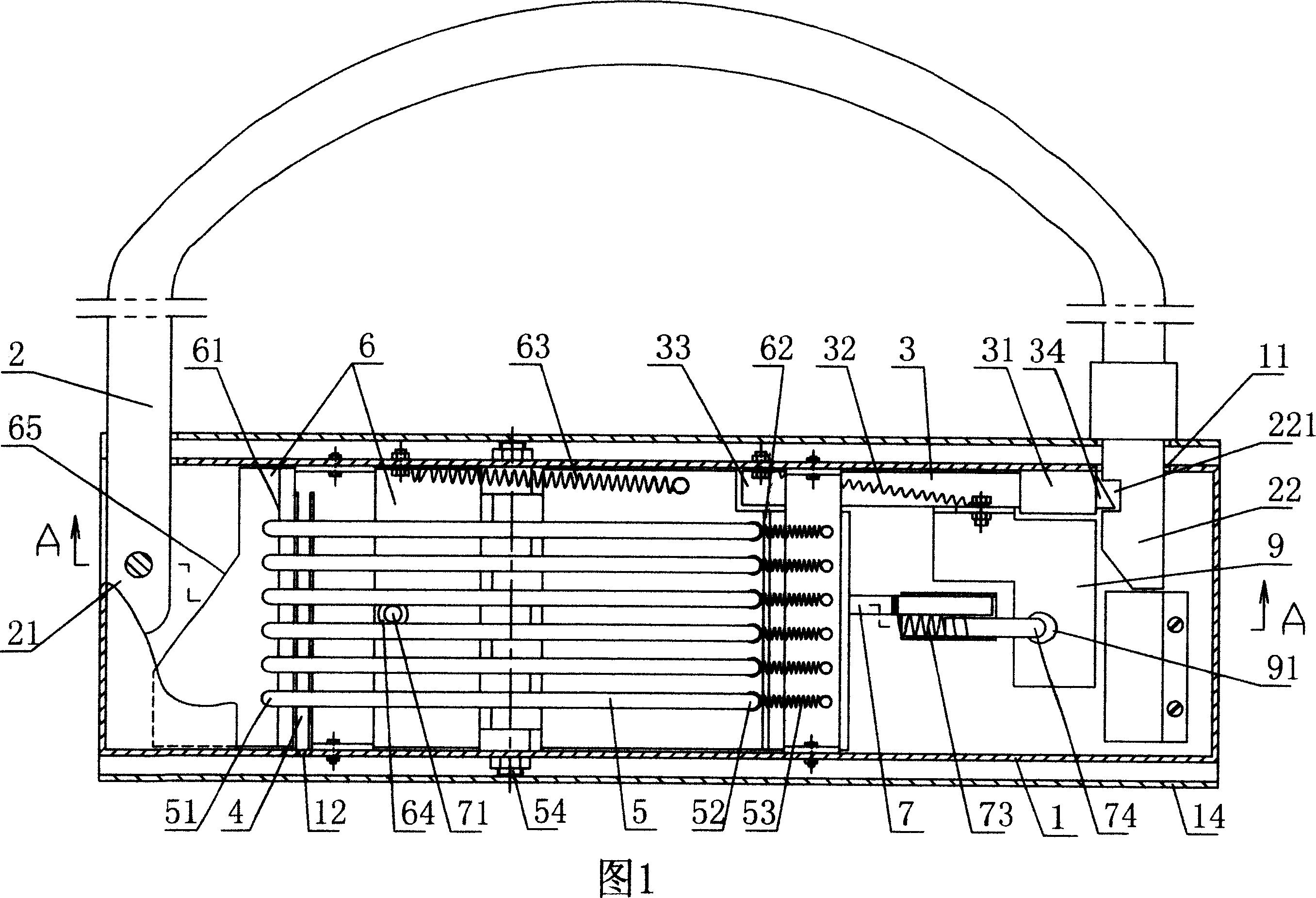

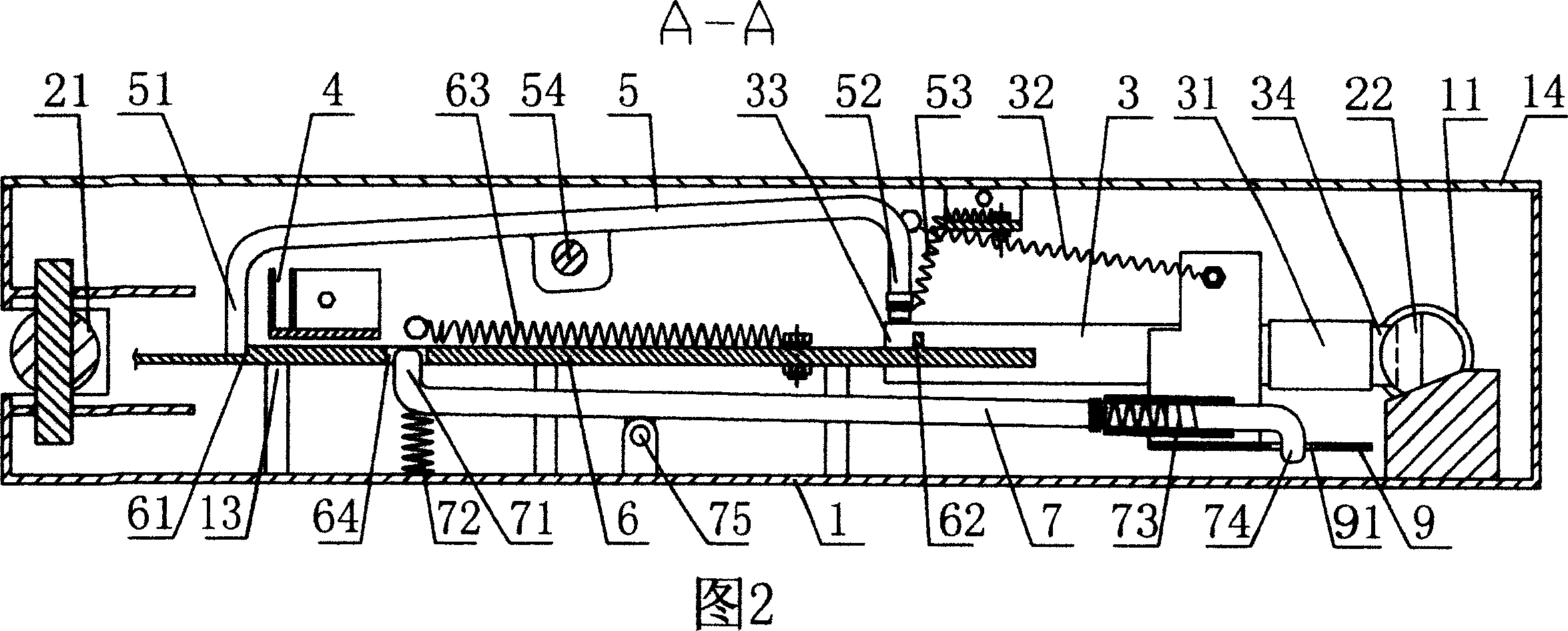

[0037] As shown in Figures 1-5, the two ends of the balance lever 5 are respectively provided with downward hook-shaped parts 51, 52, and the positions corresponding to the hook-shaped parts 51, 52 at the upper two ends of the first locking plate are respectively provided with limiting protrusions. Edges 61, 62; when the key was not inserted into the key passage, one end 51 of each balance lever close to the key passage was pressed down under the action of its return spring 53, and buckled the limit flange on the corresponding side of the first locking plate to hinder It moves away from the lock hole; when the key is inserted into the key passage, each balance lever is lifted to the balance position, that is, the hook-shaped parts at both ends of each balance lever are higher than the flanges at the two ends of the first locking plate at the same time, so that Unhinder the first locking plate.

Embodiment 2

[0039] As shown in Figures 6 and 7, the first locking plate is provided with an upward limit stopper 66, which is located at the end 51 of the balance lever close to the keyway and towards the side of the lock hole, and the limit stop The middle part of the block is provided with a relief groove 67; when the key is not inserted into the key passage, one end 51 of each balance lever close to the key passage is pressed down under the action of its return spring 53, and contacts with the protrusion of the limit stop , preventing the first locking plate from moving away from the lock hole; when the key is inserted into the key passage, each balance lever is lifted to the equilibrium position, that is, each balance lever is raised to the limit stop at the same time as one end 51 of the key passage The position of the relief groove, thereby can remove the hindrance to the first locking plate (one end 51 of each balance lever close to the keyway can relatively move in the relief groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com