Preform conveyor system provided with means for ejecting badly seized

A conveying system, technology for preforms, applied in the direction of conveyors, conveyor items, transport and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] [35] Hereinafter, the same, similar or analogous elements will be assigned the same reference numerals.

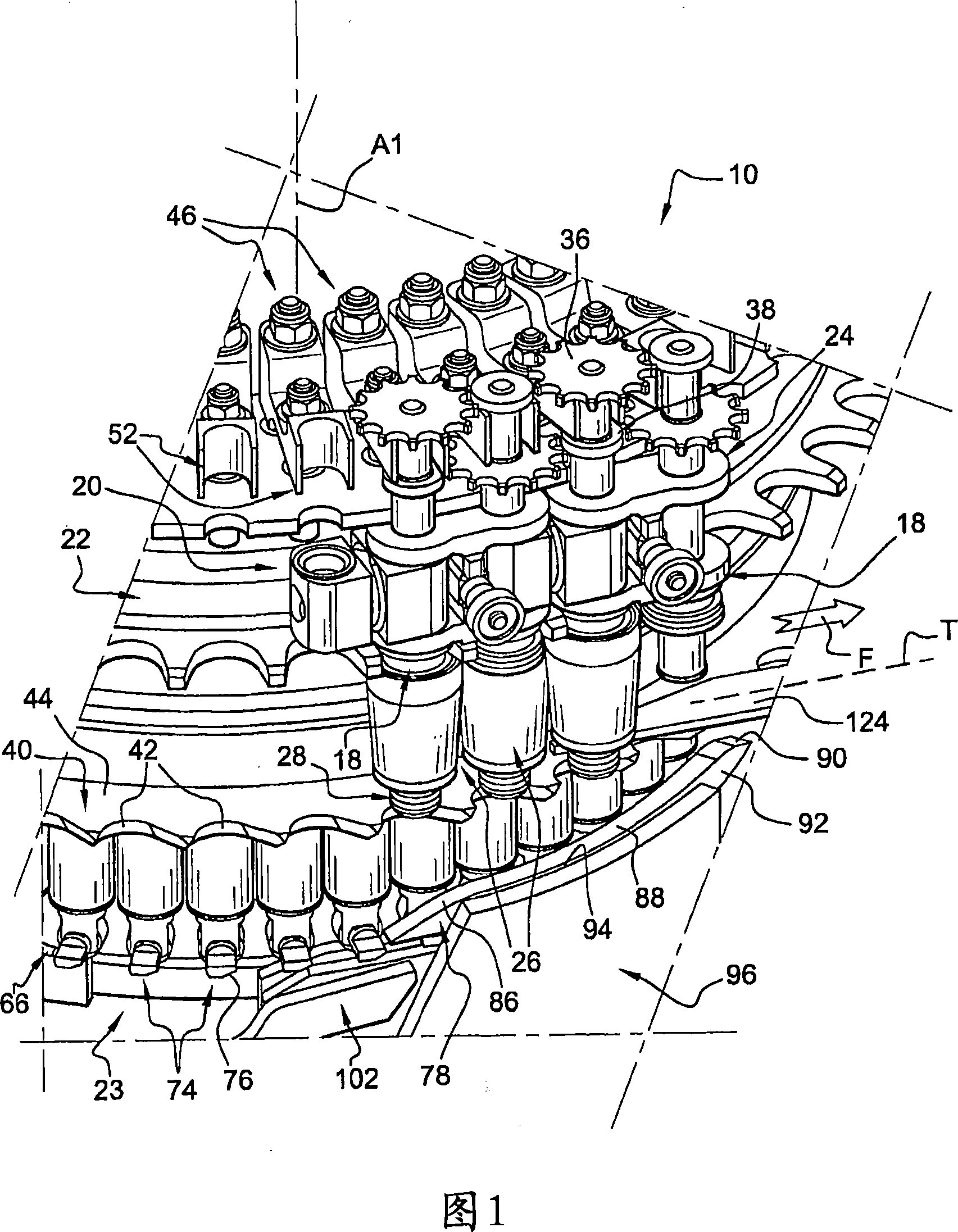

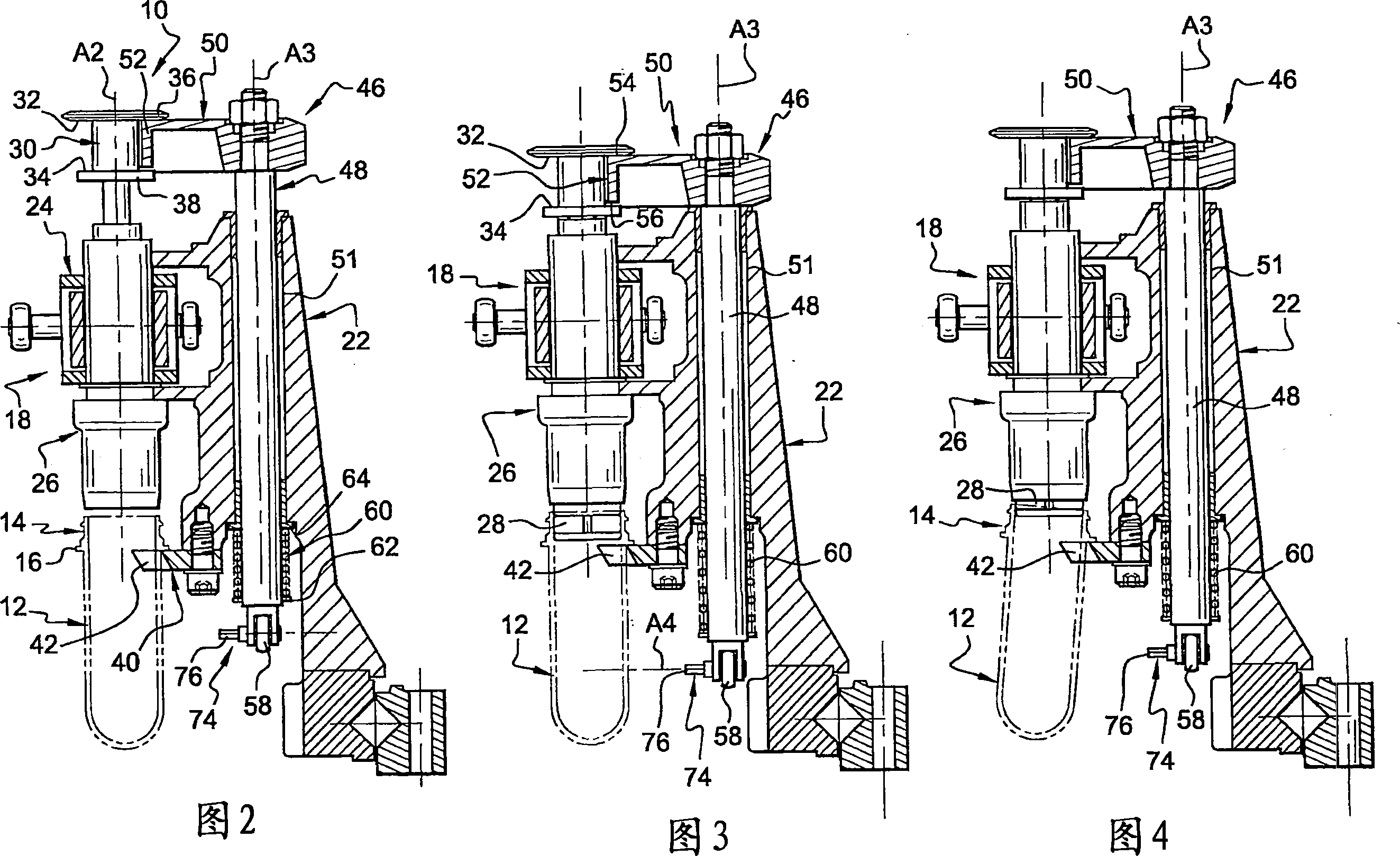

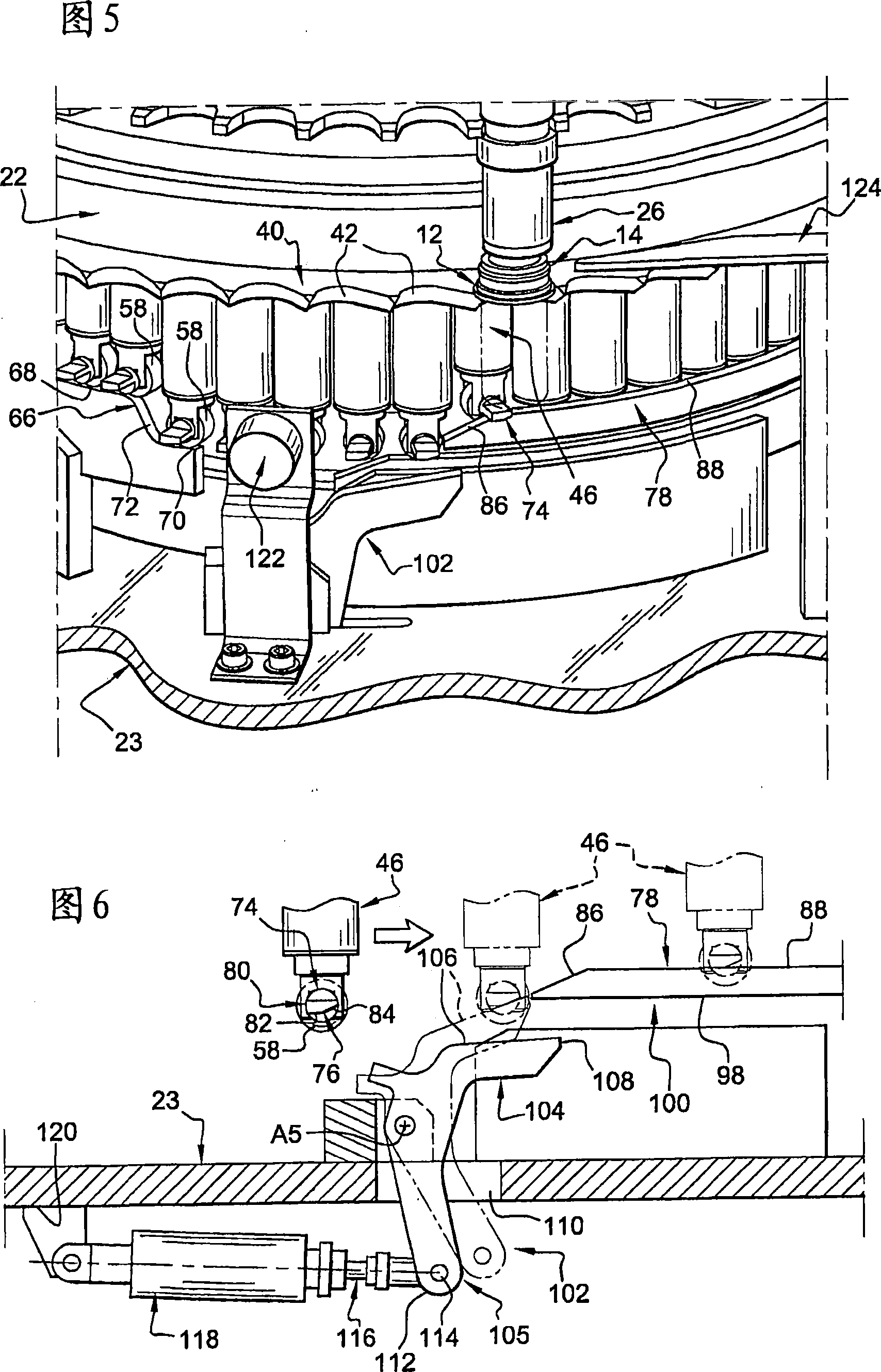

[0036] [36] FIGS. 1 to 4 show a delivery system 10 of a plant for manufacturing containers of thermoplastic material by blow molding from preforms 12 obtained beforehand by injection moulding.

[0037] [37] Each preform 12 is in tubular form, closed at one end and having at its other end the defined shape of a container neck 14 obtained by preworking, defined towards the top by an external annular coupling 16 its boundaries.

[0038] [38] The conveying system 10 comprises a plurality of conveying elements 18 interconnected so as to form an endless chain 20 and designed to convey the preforms 12 in the downstream direction indicated by the arrow F in FIG. 1 .

[0039] [39] Only a portion of the chain 20 is shown in FIG. 1 . This part of the chain 20 comprises in this example two conveying elements 18 .

[0040] [40] The chain 20 part of the conveying element 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com