Bearing-holder support for rotating elements

A technology for rotating components and bearing seats, which is applied in the direction of rotating bearings, rigid supports of bearing components, bearings, etc., which can solve the problems of difficult manufacturing and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

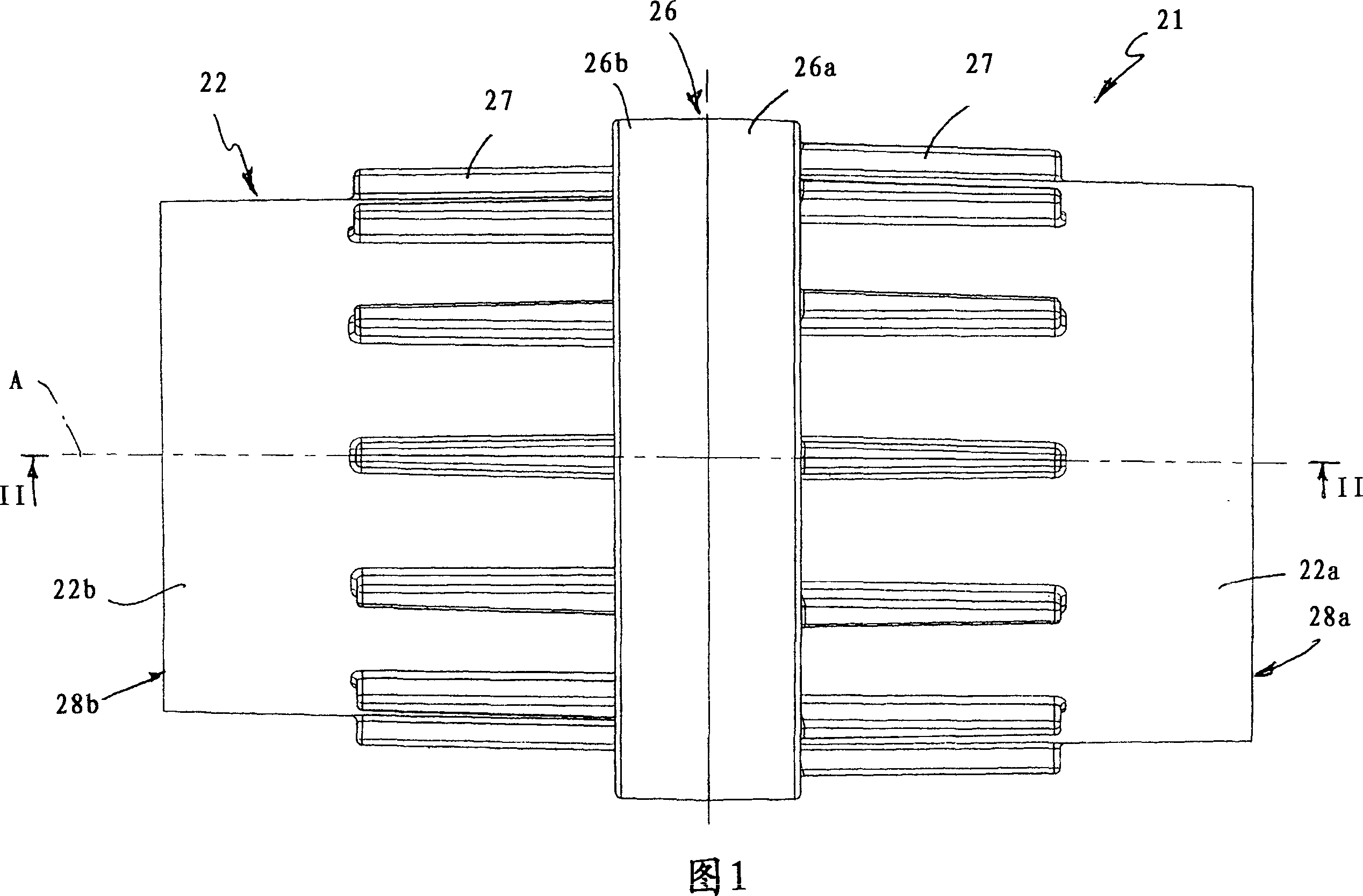

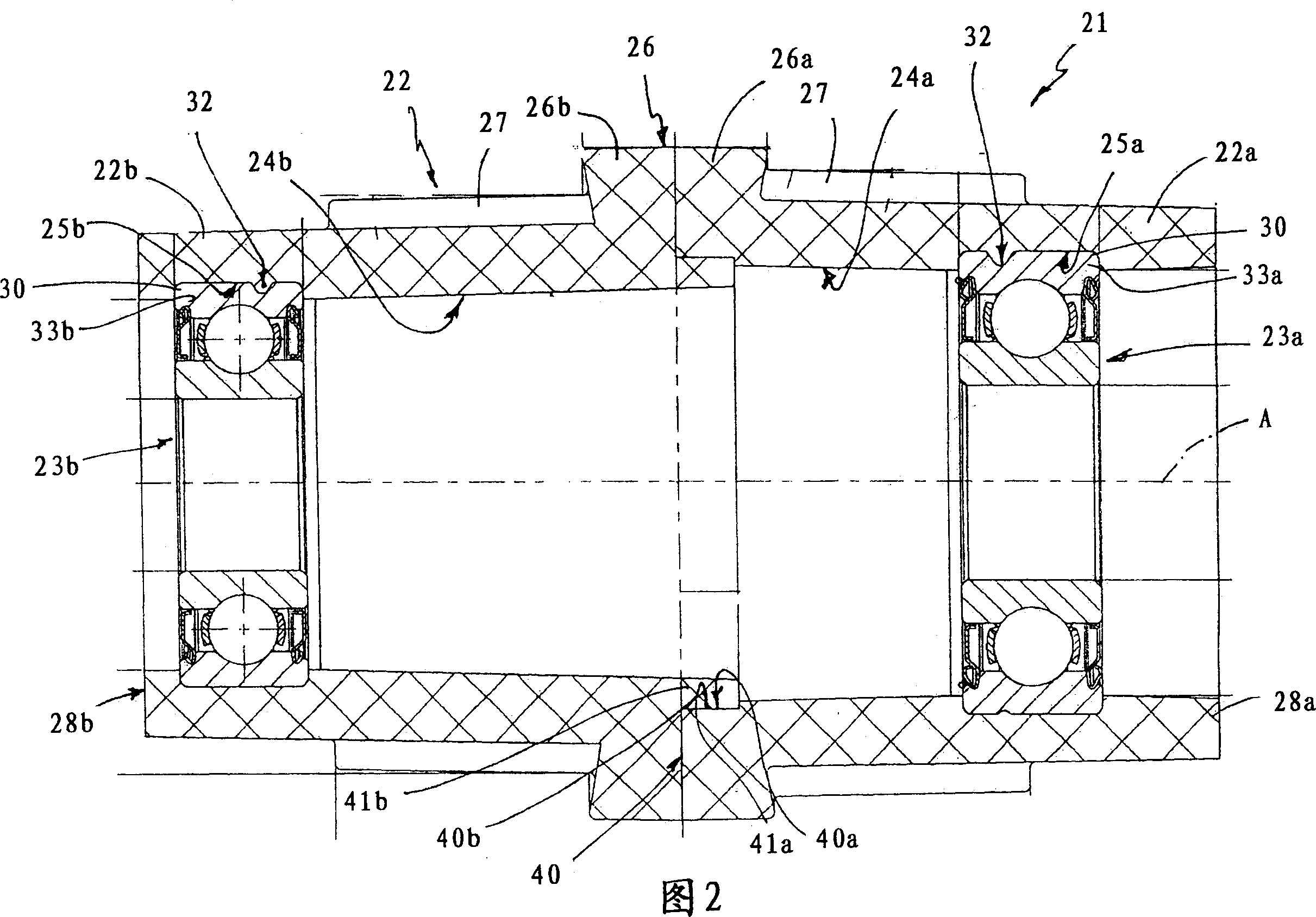

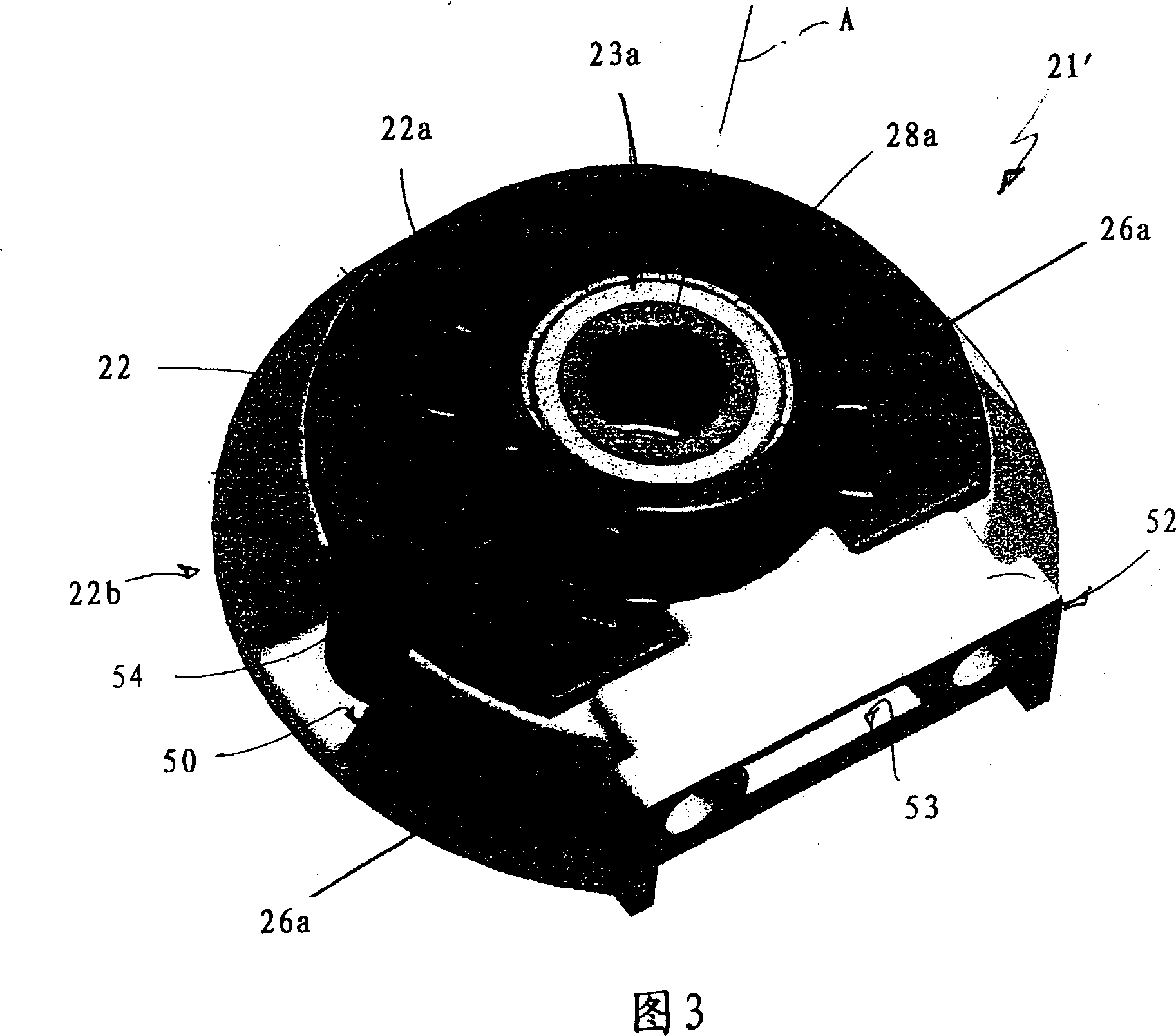

[0019] With reference to Figures 1 and 2, the same or similar parts as described hereinbefore up to the content of this specification are designated by the same reference numerals, the number 21 designating the whole of the bearing housing support for the rotating element, which is represented by the previous Delimited by a tub 7 of a loading washing machine 5 , the front-loading washing machine comprises a tub 6 , a tub 7 and a motor shaft 11 for actuating the tub 7 itself.

[0020] The cylinder 6 is made of plastic material and has, on the side opposite said loading side, a tubular casing 15 extending along the axis A, in which the bearing block support 21 is adapted to be housed so that The motor shaft 11 cooperates therethrough and allows the rotation of the cartridge 7, which is arranged suspended on the shaft 11 itself.

[0021] The support 21 comprises a tube 22 made of plastic material and two rolling contact bearings 23a, 23b, preferably arranged in the tube 22 itself...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com