Arrangement for bearing for a seat

a technology which is applied in the field of arrangement for swinging seats and bearings, can solve the problems of difficult to sense where the desired movement is going to stop, the damping element is not suitable for mounting swinging seats, and the user has a certain feeling of instability, so as to improve the service life and improve the effect of mass production and instooling in different seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

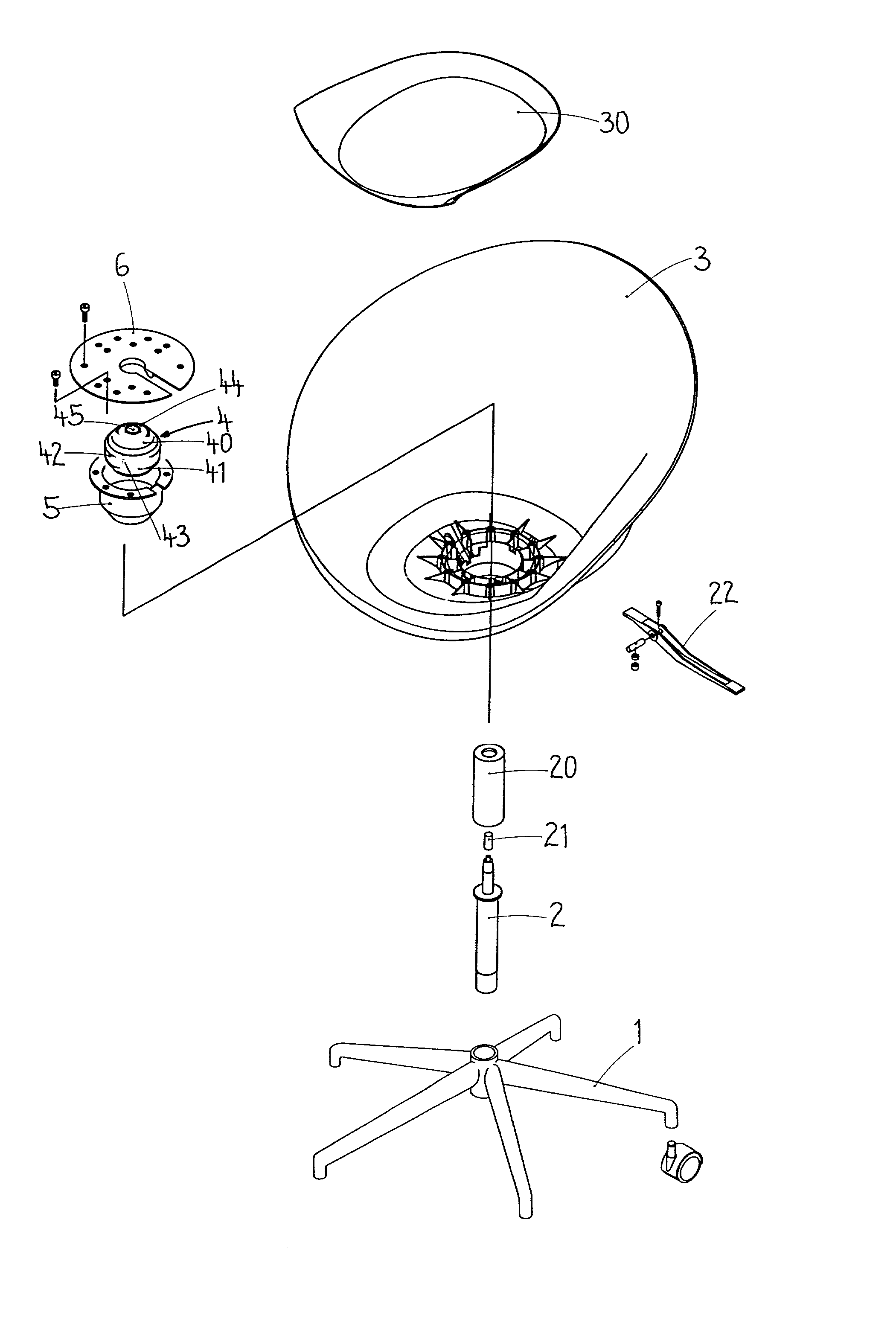

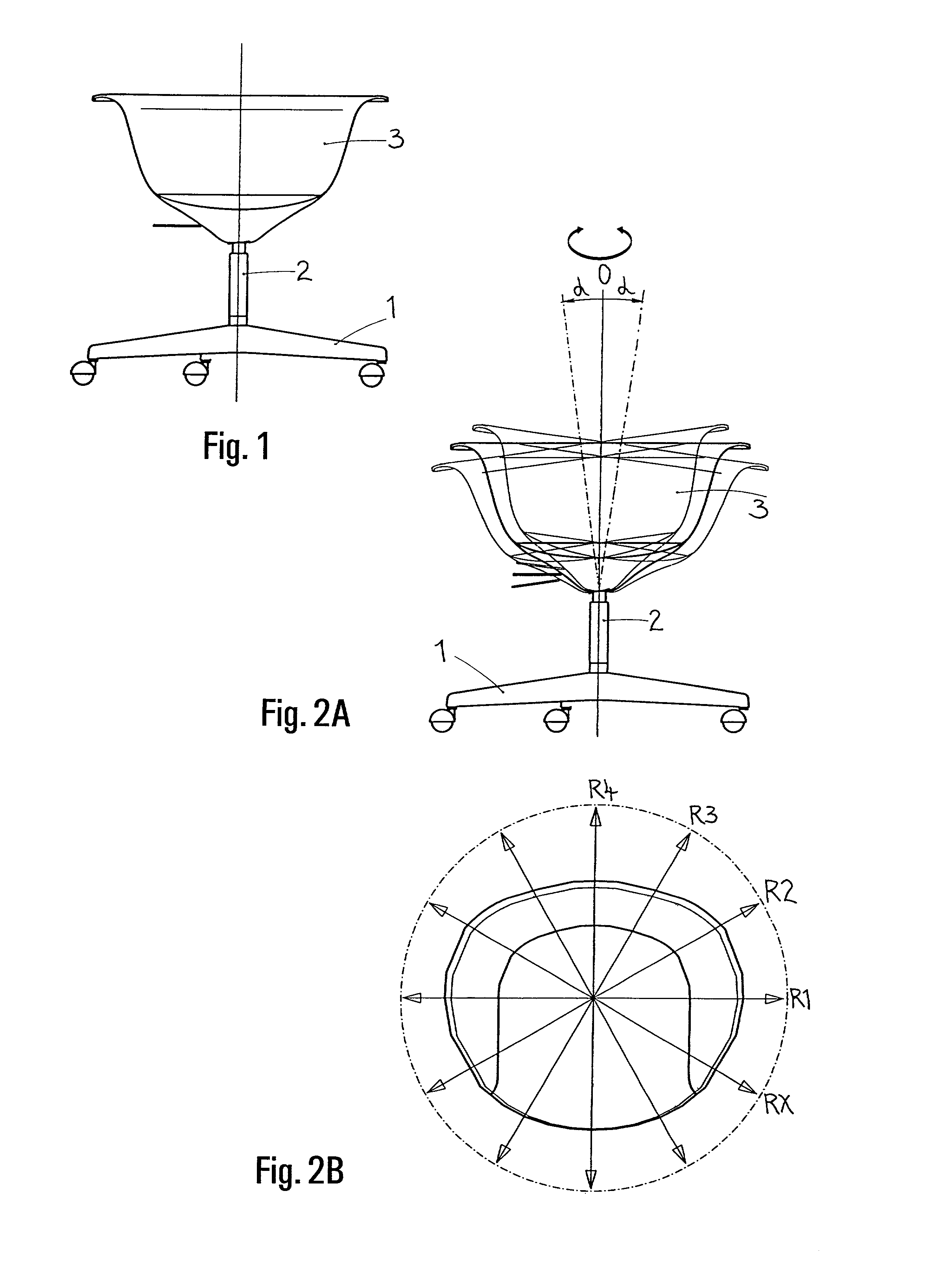

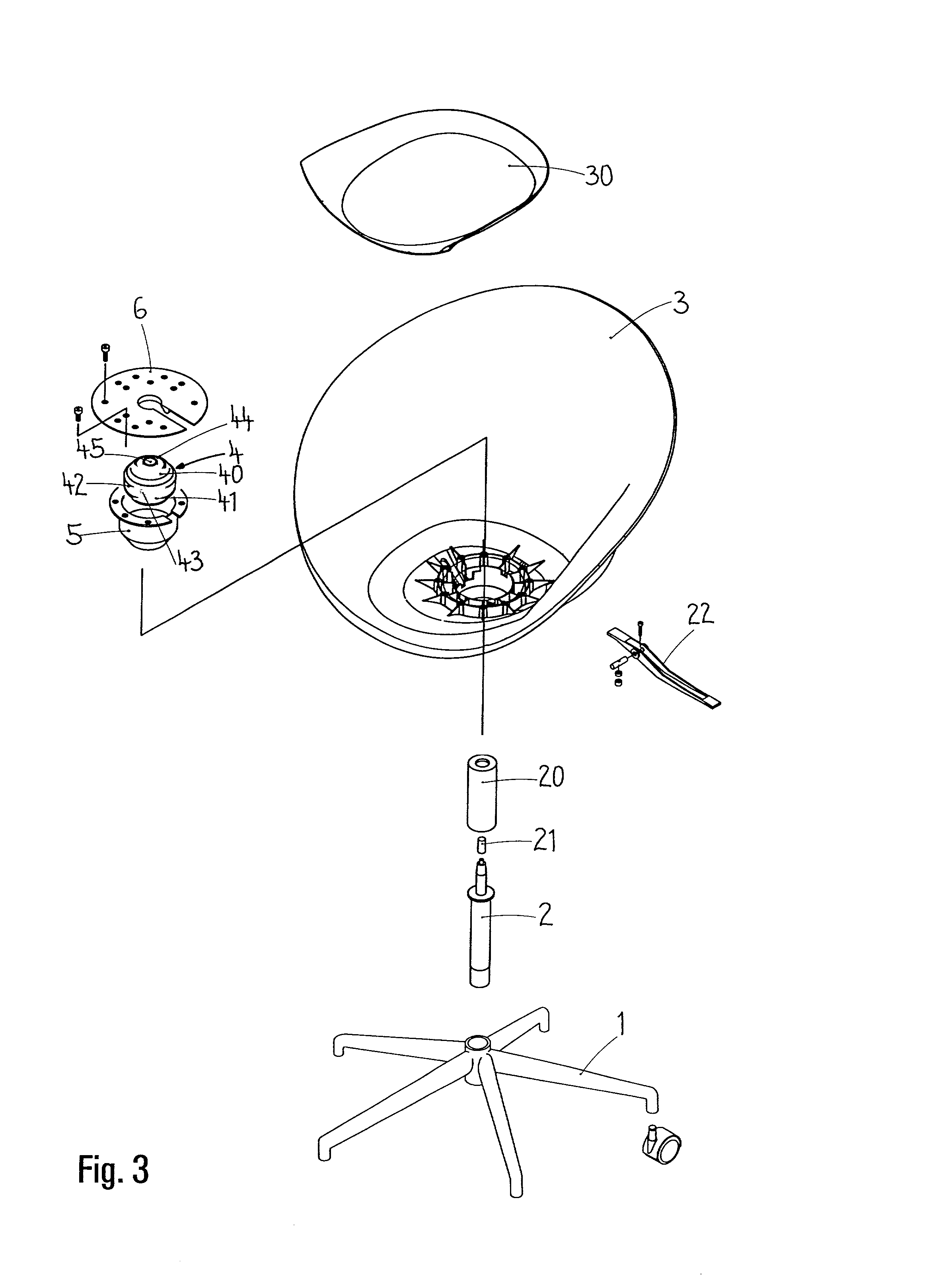

[0037] The underframe 1, the central column 2--typically a pneumatic spring--and a shell-like seat 3 are provided here. It is also possible to see a tubular pneumatic-spring covering 20 and a cylindrical push-rod extension 21. A triggering lever 22 fitted beneath the seat 3 is provided for actuating the pneumatic spring 2. the mounting comprises a first variant of a spring element 4, a bottom, cup-like casing 5 and a top molding 6, in this case in the form of a cover plate which is intended for fastening on the top side of the base of the seat 3. Finally, a seat-cushion panel 30, which covers the top molding 6, is provided. The spring element 4 is roughly cylindrical with reduced-diameter sections 40,41 at the top and bottom, a central section 42, an outer sleeve 43, a core 44 and an axial through-passage 45, the latter running through the core 44.

[0038] FIG. 4A

[0039] In the case of the first embodiment of the mounting, in the instooled state, the first variant of the spring element...

second embodiment

[0048] the seat mounting according to the invention is illustrated here. Once again, an underframe 1, a central column 2--preferably a pneumatic spring--a seat 3, the spring element 4, the bottom casing 5' and a top molding 6' are provided for this chair. The special feature here is that, rather than being formed by a separate plate, the top molding 6' is formed by a correspondingly contoured aperture 60' in the seat carrier 6'. The aperture 60' encloses the top section 40 of the spring element 4 in the same way as the shaped collar 60. The cutout 61' is provided again in the seat carrier 6'. The casing 5' is inserted into the aperture 60' by way of its top border, is enclosed by the seat carrier 6' and is connected to the latter, the spring element 4 being more or less encapsulated in the process. The cutout 61' provides the freedom of movement as deflection from the rest position 0.

[0049] If use is made of the first variant of the spring element 4 (according to FIG. 6A), as is the...

third embodiment

[0051] In the case of this third embodiment of the seat mounting, use is made of a third variant of a spring element 4, which is likewise intended for fitting onto a central column 2. The sheath-like core 44 has an axial through-passage 45 for accommodating the top end of the central column 2, preferably a pneumatic spring with a telescopically extensible lifting rod. It is advantageous if the axial through-passage 45, to complement the lifting rod, narrows conically upward.

[0052] The core 44, consisting, for example, of steel, has an encircling shoulder surface 442, which is preferably produced by an outside cone with a diameter which tapers in an upwardly sloping manner. A conical outer sleeve 43 made of elastic material, e.g. rubber, is arranged on the shoulder surface 442. The outer sleeve 43 is enclosed by a top molding 600, with the result that the latter constitutes a casing 600 for the outer sleeve 43. In order to ensure optimum functioning, the core 44 should be fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com