Pulp pump

a centrifugal pump and pulp technology, applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of deteriorating the capacity affecting the efficiency of the pulp pump, and causing problems such as pulp pump becoming relatively complicated and expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

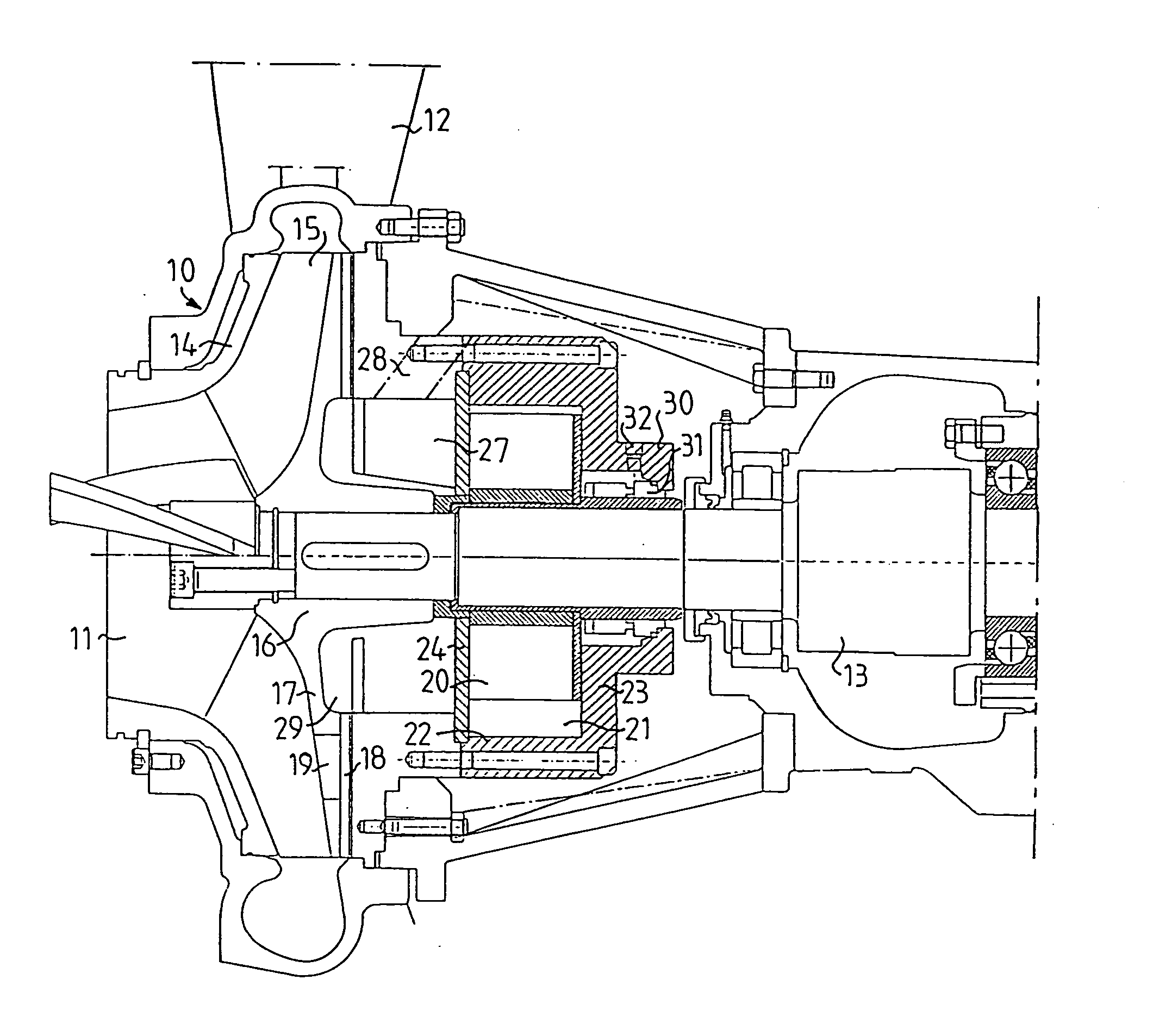

[0012] The centrifugal pump shown in FIG. 1 comprises a pump housing 10 with an inlet 11 and an outlet 12 for the pulp suspension. Such pumps are used at relatively high pulp concentration, for example from about 6% to 18%. On a rotary shaft 13 in the pump housing 10 an impeller 14 is mounted, the pump blades 15 of which extend from a hub 16 outward along a wheel disk 17. On the rear side of the wheel disk 17 back blades 18 are located. The wheel disk 17 is further formed with openings 19 for the discharge of gas collected in front of the impeller.

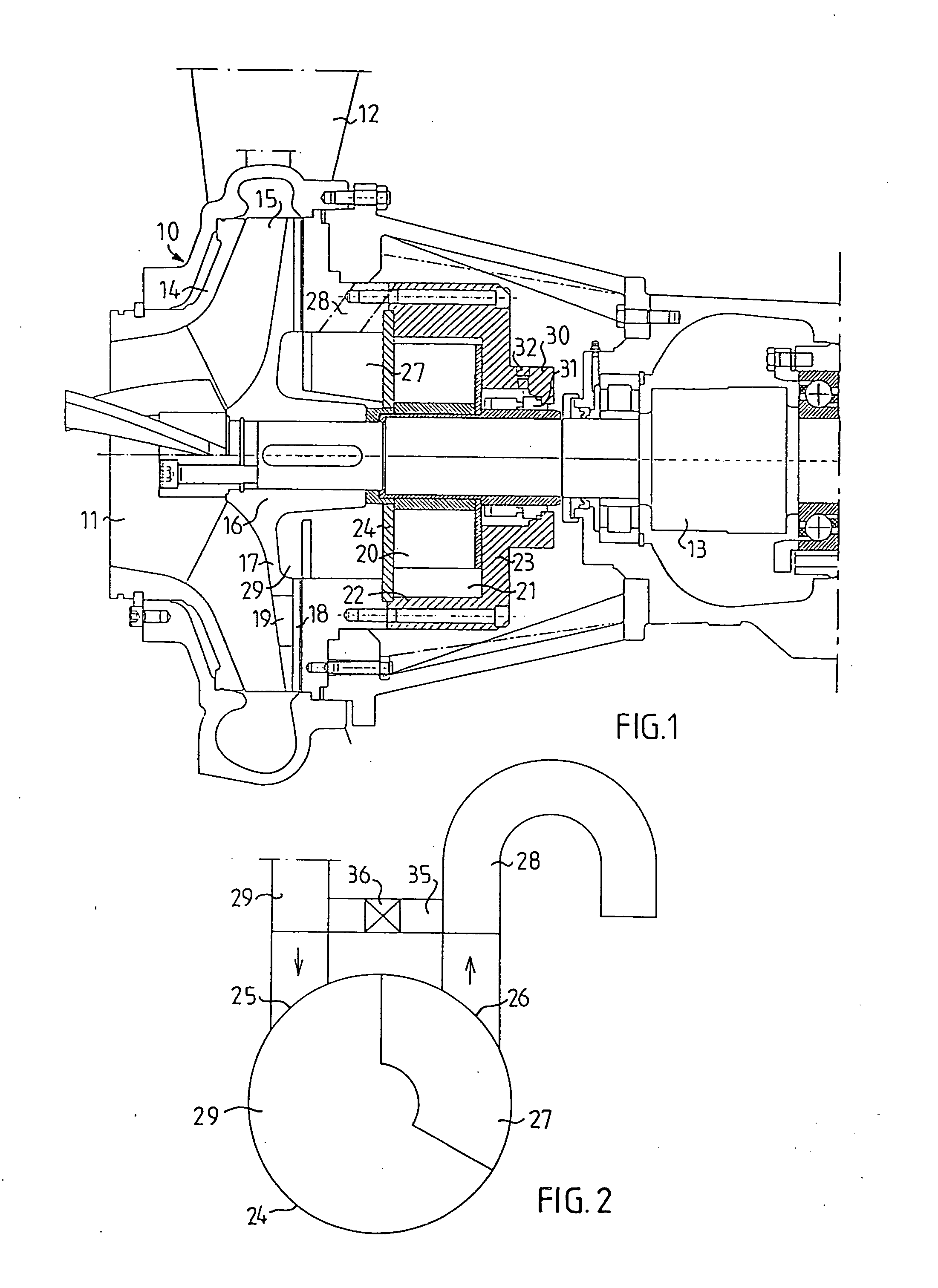

[0013] Behind the impeller 14 a vacuum impeller with vacuum impeller blades 20 is located, which impeller is surrounded by a vacuum pump housing 21. This vacuum pump housing 21 comprises an outer cylindrical wall 22, a rear wall 23 and a front wall 24. The cylindrical wall 22 is eccentric in relation to the vacuum impeller blades 20, so that a liquid ring pump is formed. In the front wall 24 a suction port 25 for gas and an exhaust port 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| vacuum | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com