Anti-slip step for a motor vehicle and a method of forming the same

a technology of anti-slip steps and motor vehicles, applied in the field of steps, can solve the problems of rosette clogging with dirt or ice, step is quite slippery, and major surfaces can become slippery,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that in the detailed description that follows, identical components have the same reference numerals, regardless of whether they are shown in different embodiments of the present invention. It should also be noted that in order to clearly and concisely disclose the present invention, the drawings may not necessarily be to scale and certain features of the invention may be shown in somewhat schematic form.

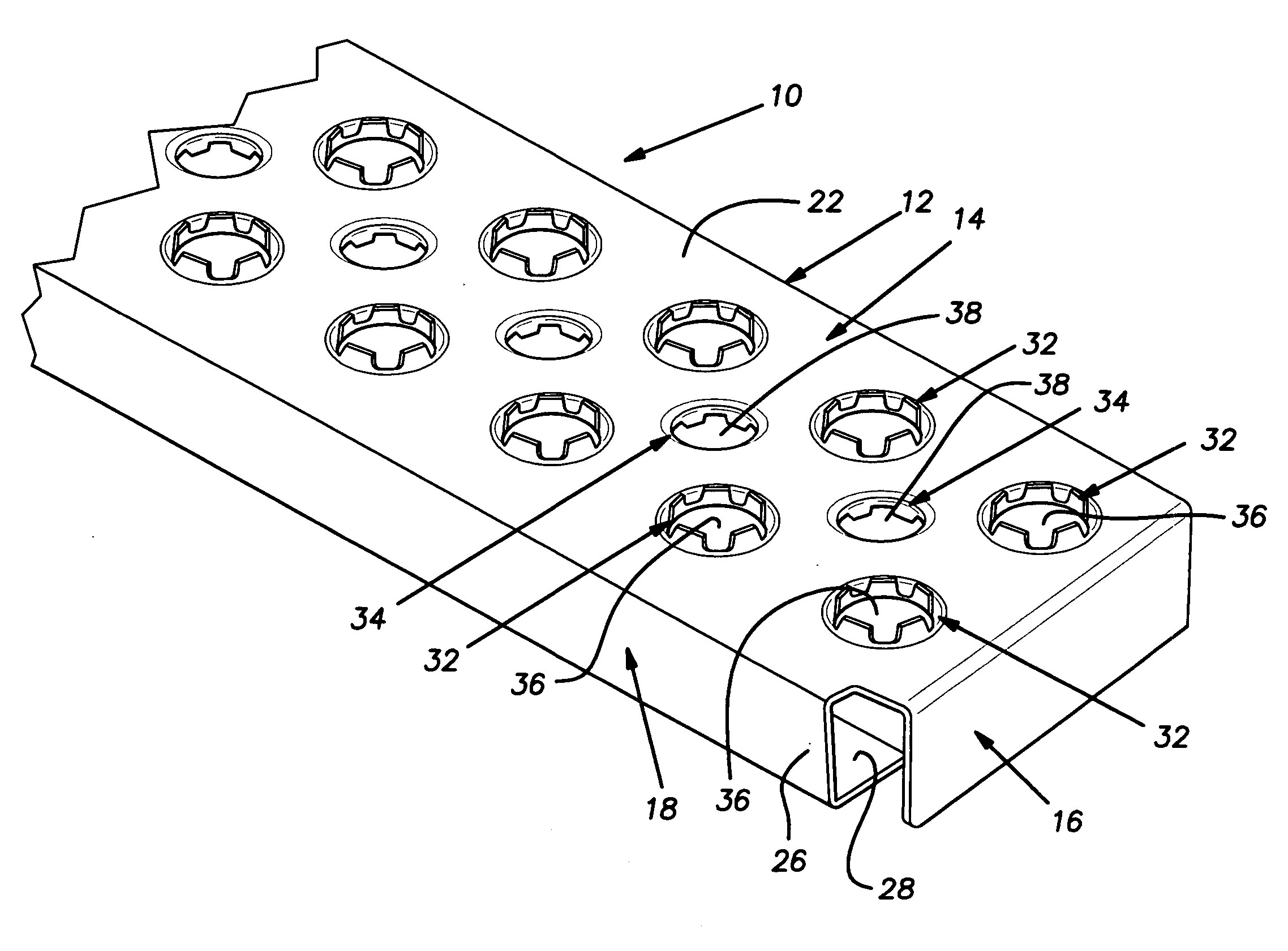

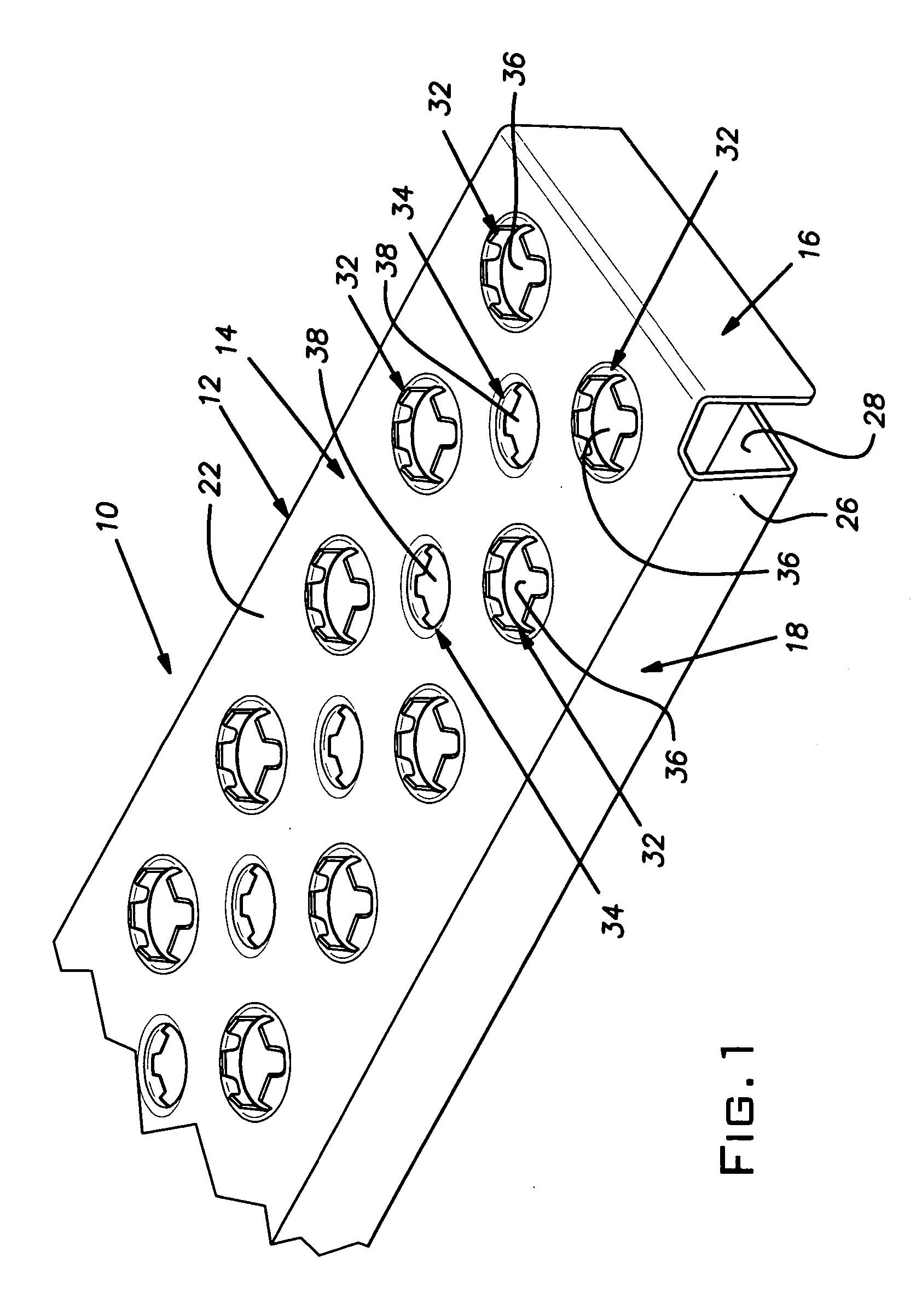

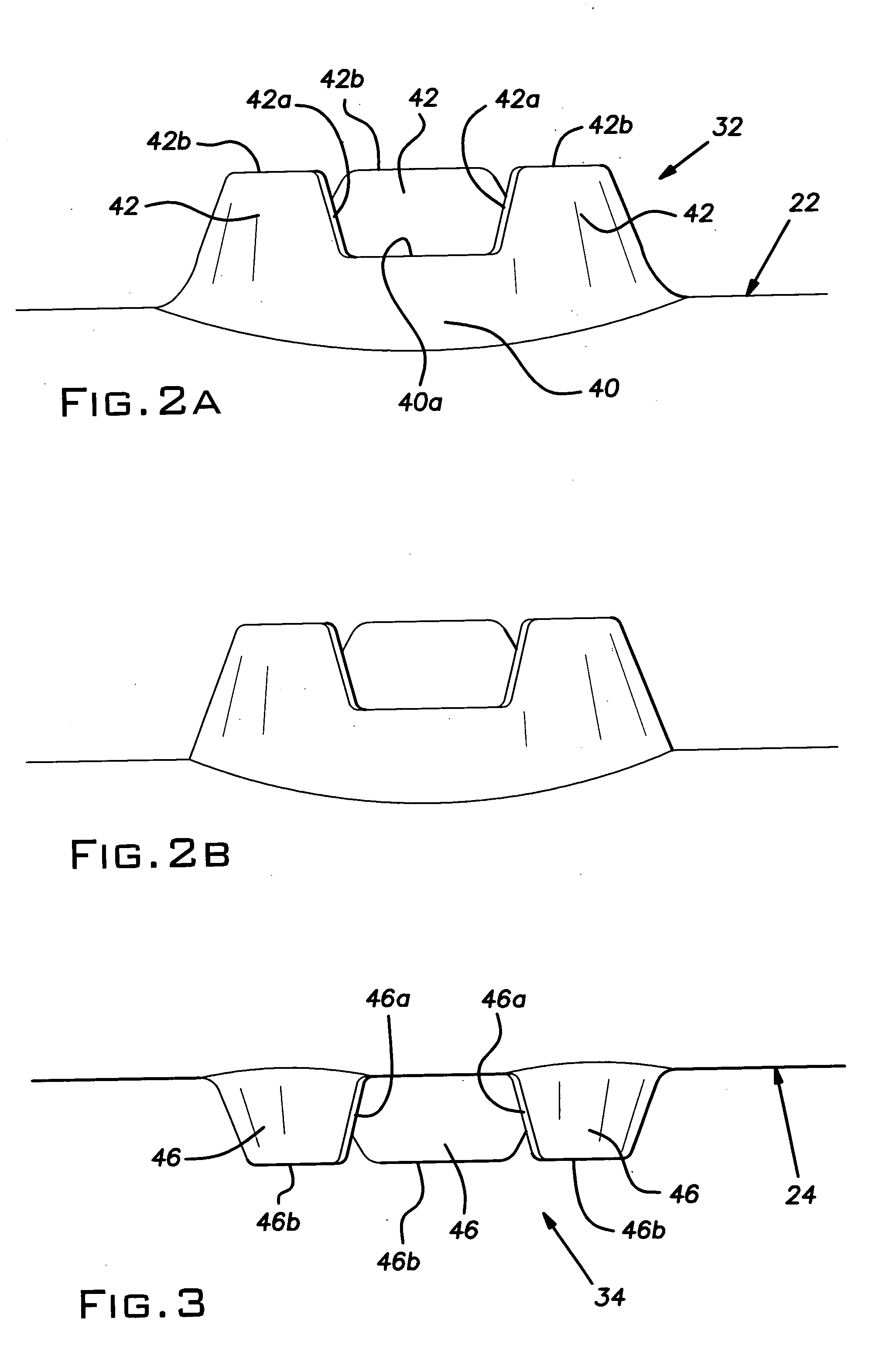

[0018] Referring now to FIG. 1, there is shown a portion of a step 10 embodied in accordance with the present invention. The step 10 is adapted for installation on a motor vehicle, especially an industrial truck having an elevated cab, such as a dump truck or a tractor for pulling a semitrailer. The step 10 includes a support structure 12 that is preferably composed of a metal, such as aluminum. The support structure 12 includes a tread plate 14, a pair of opposing end flanges 16, front flange 18 and a rear flange (not shown). The tread plate 14 is rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com