In-line security hook

a hook and security technology, applied in the field of security hooks, can solve the problems of ineffective design and inability to engage the s-hook, and achieve the effect of preventing inadvertent disengagement of the chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

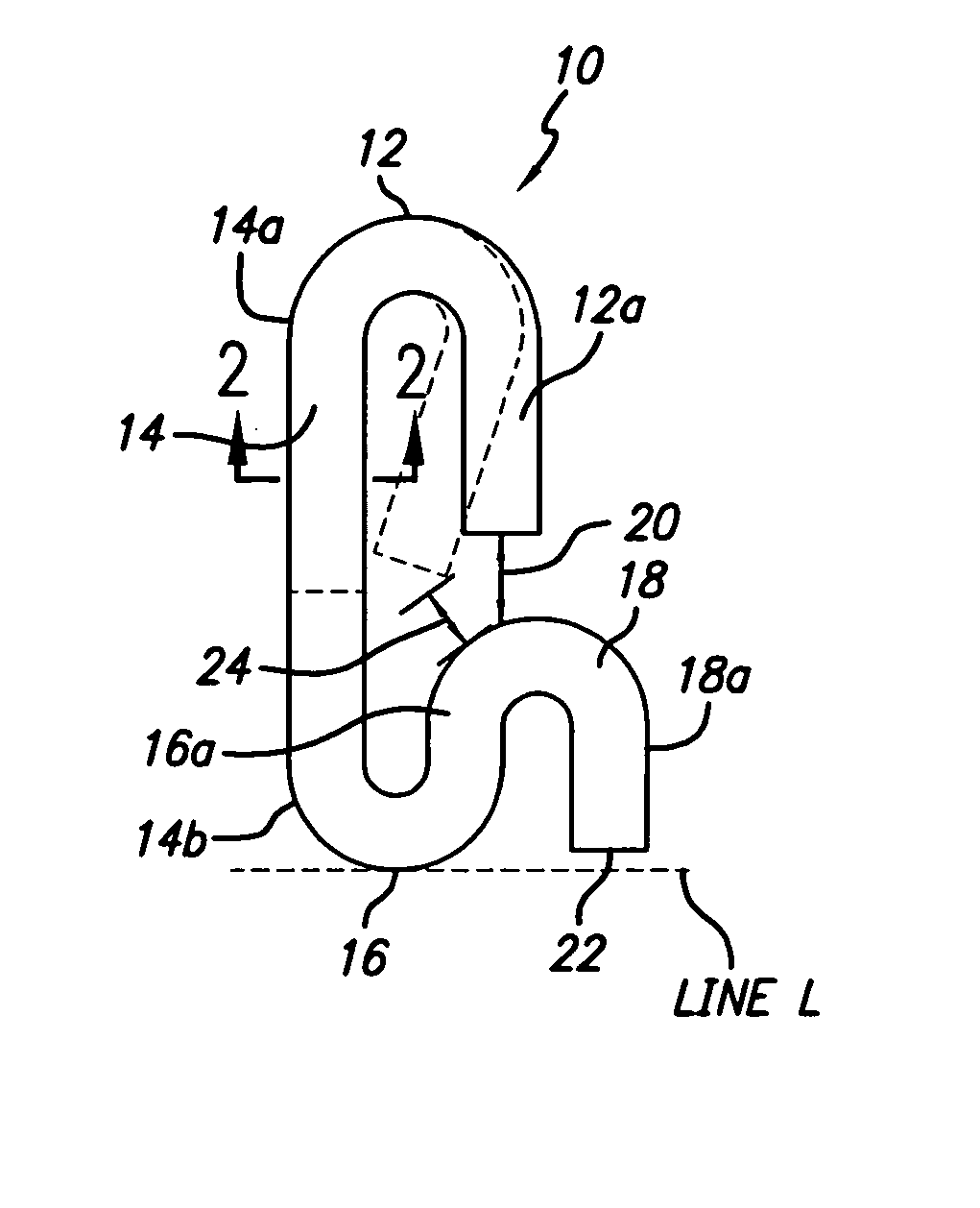

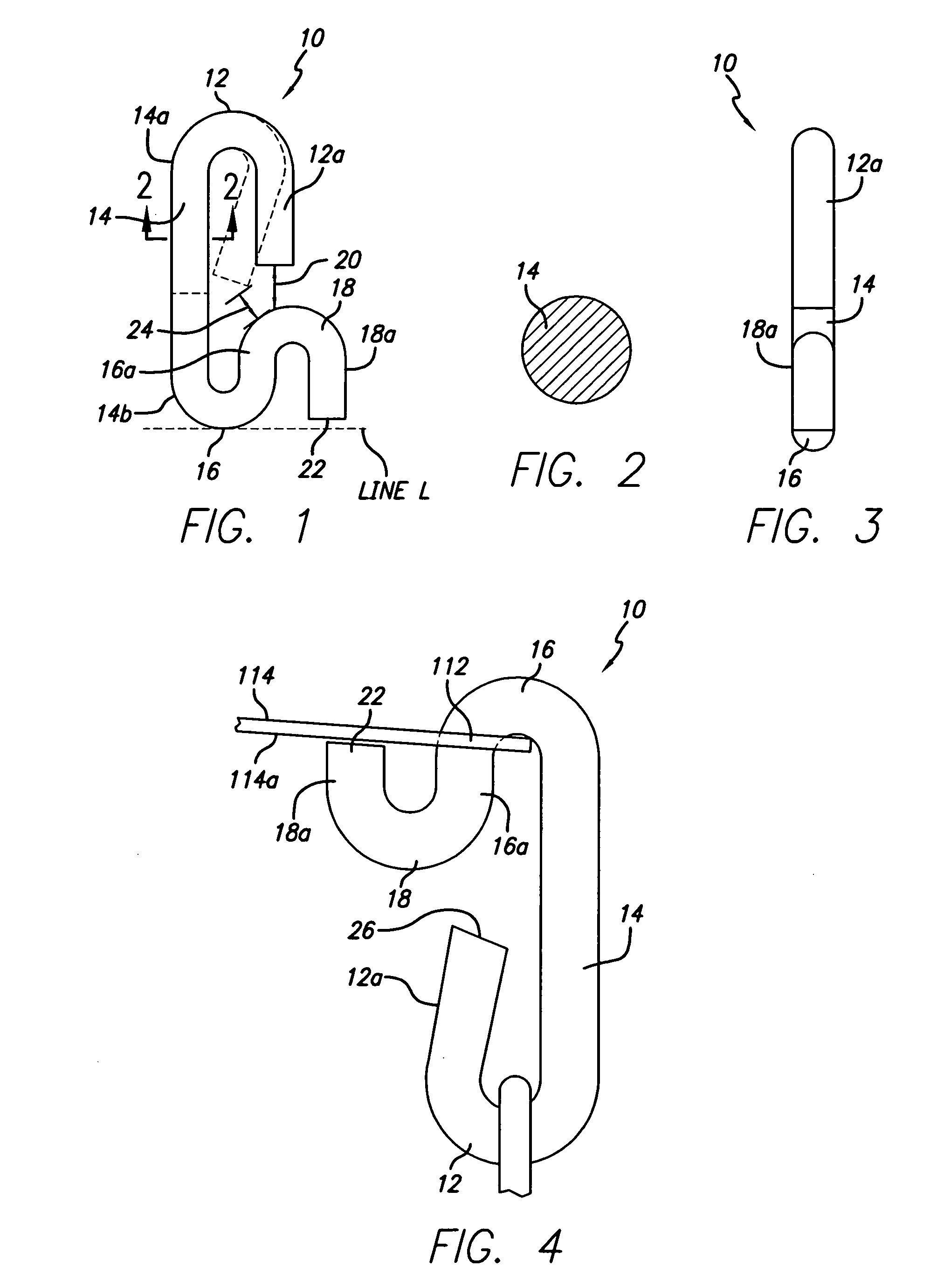

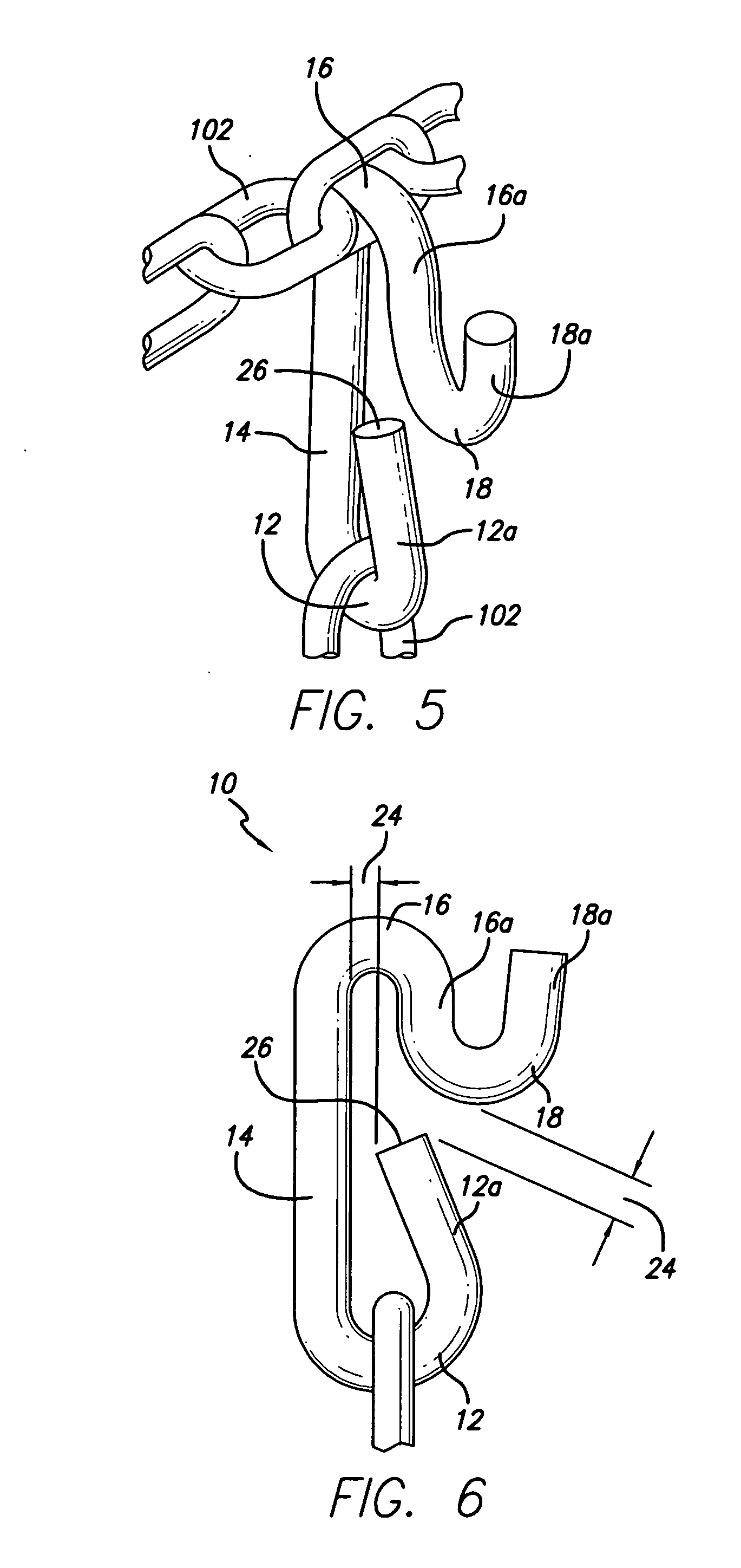

[0005] A security hook is disclosed having a main shaft, a chain receiving portion extending from a first end of the main shaft and a first bend extending from a second end of the main shaft. The chain receiving portion and first bend are preferably, but not necessarily, positioned on the same side of the main shaft and are substantially in-line with each other. A second bend extends from the first bend in the opposite direction of the first bend. The security hook, including the main shaft, the chain receiving portion and the first and second bends, is preferably made of an integral metal bar capable of withstanding relatively high forces.

[0006] In one embodiment of the invention, the first and second bends each have a straight portion and the second bend extends from the straight portion of the first bend. The straight portions are substantially parallel to the main shaft. The chain receiving portion also includes a straight portion that is substantially parallel to the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com