Ammunition articles with plastic components and method of making ammunition articles with plastic components

a technology of plastic components and ammunition articles, applied in the field of ammunition articles, can solve the problems of excessive chamber pressure, plastic cartridge casings, and inability to provide satisfactory ammunition that could be produced in commercial quantities with and achieve the effect of sufficient safety, ballistic and handling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

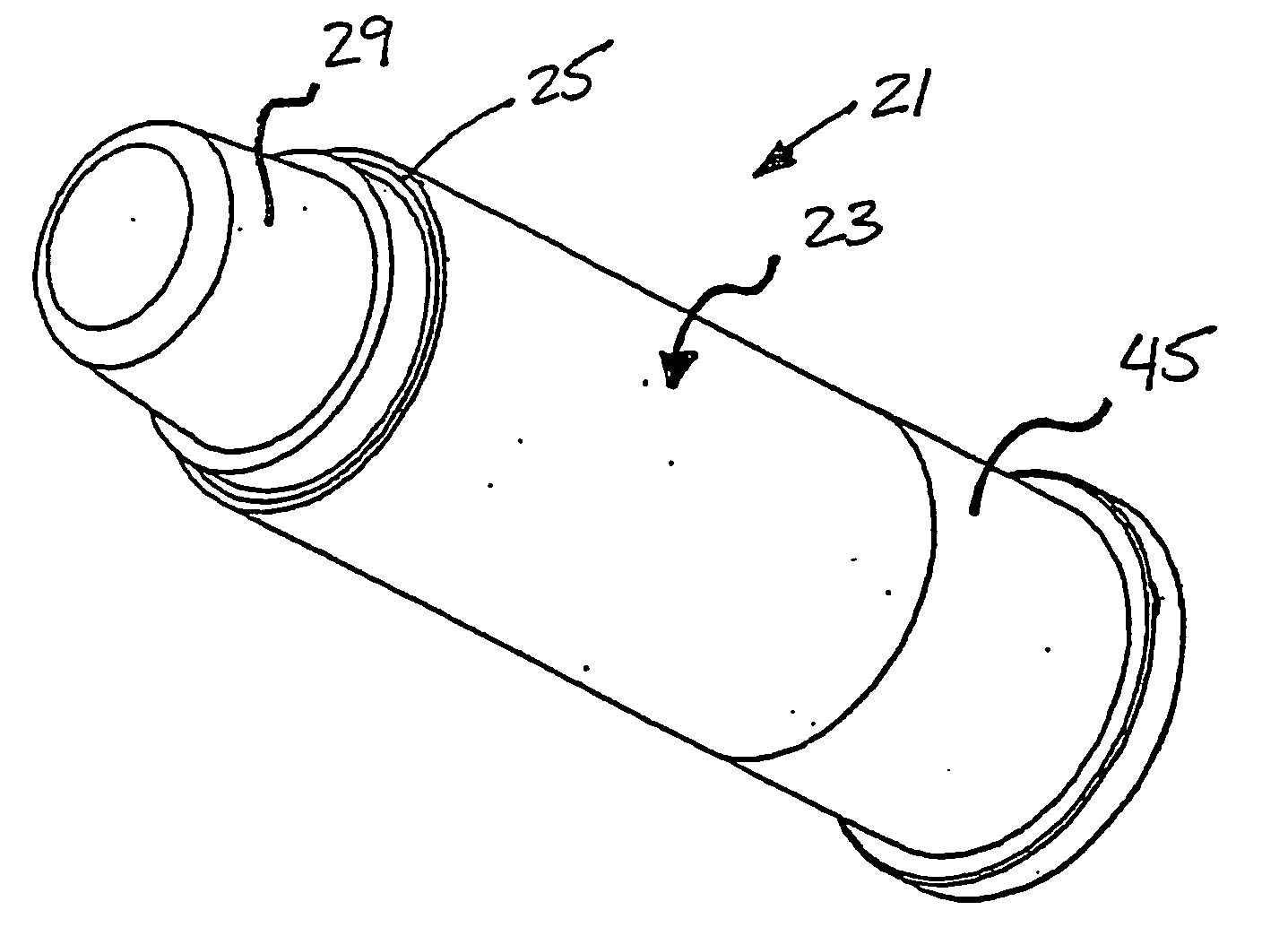

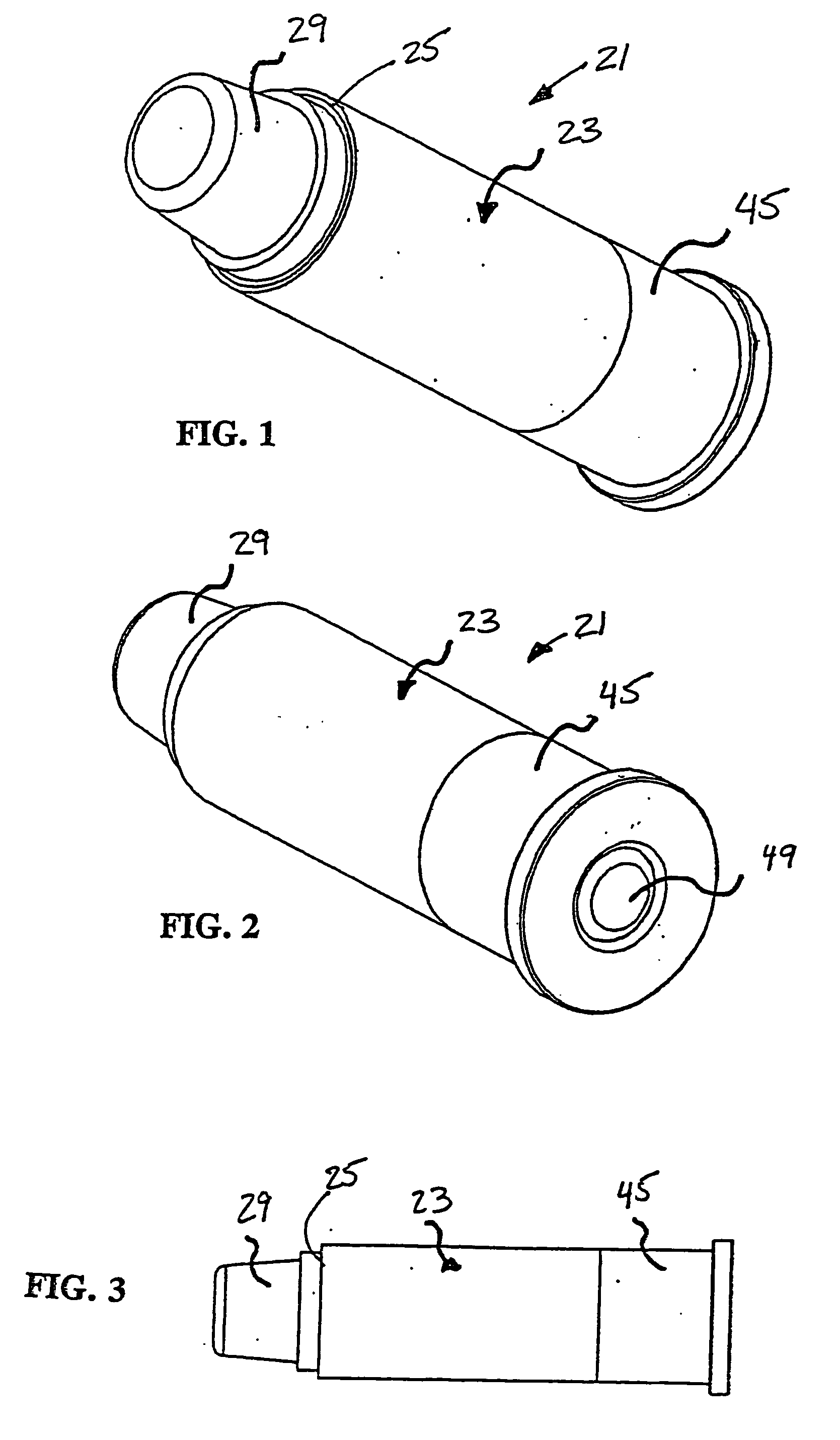

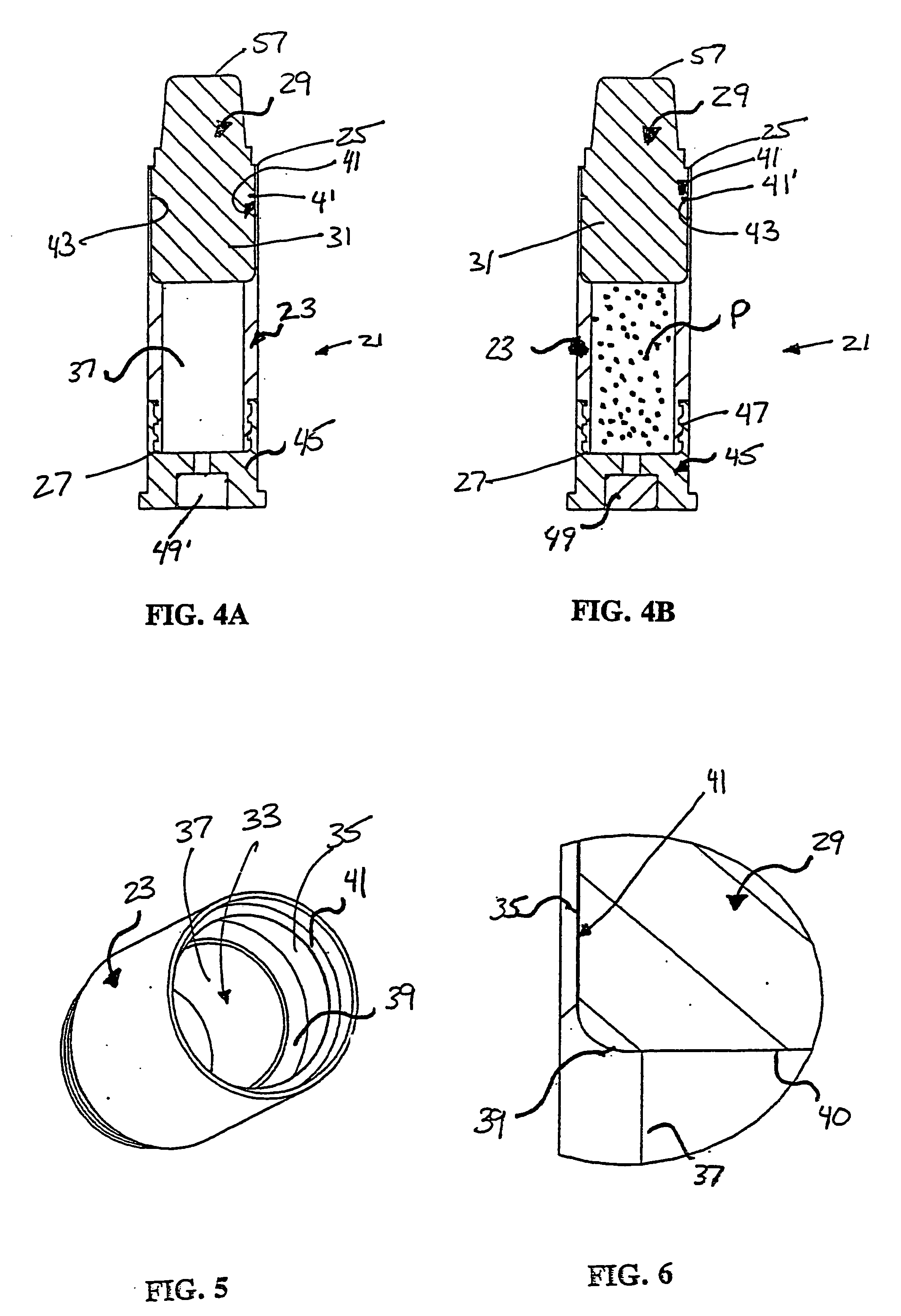

[0045] An ammunition article 21 according to an embodiment of the present invention is shown in FIGS. 1-3. As seen in cross-section in FIGS. 4A and 4B, the ammunition article 21 includes a molded plastic cartridge casing body 23 having a first end 25 and a second end 27. A projectile 29 is attached to the first end 25 of the cartridge casing body 23. The cartridge casing body 23 is a molded plastic part, and is formed by plastic being molded around at least a portion 31 of the projectile 29. As discussed with reference to FIG. 29, if desired or necessary, the cartridge casing body may be formed by plastic being molded to conform only with a bottom of a projectile, with a plastic protrusion extending into a cavity in the bottom of the projectile. The projectile 29 is preferably any one of the wide variety of well-known projectiles but may, if desired or necessary, include one or more features useful in connection with the present invention.

[0046] As seen in FIG. 5 (showing the cartr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com