Micro trench duct placement

a micro-torch duct and trench technology, applied in the direction of service pipe systems, instruments, mechanical equipment, etc., can solve the problems of large surface destruction, difficult excavation, and difficulty in supplying fiber optic cabling to the many locations,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following detailed description of the invention refers to the accompanying drawings. The same reference numbers in different drawings may identify the same or similar elements. Also, the following detailed description does not limit the invention. Instead, the scope of the invention is defined by the appended claims and their equivalents.

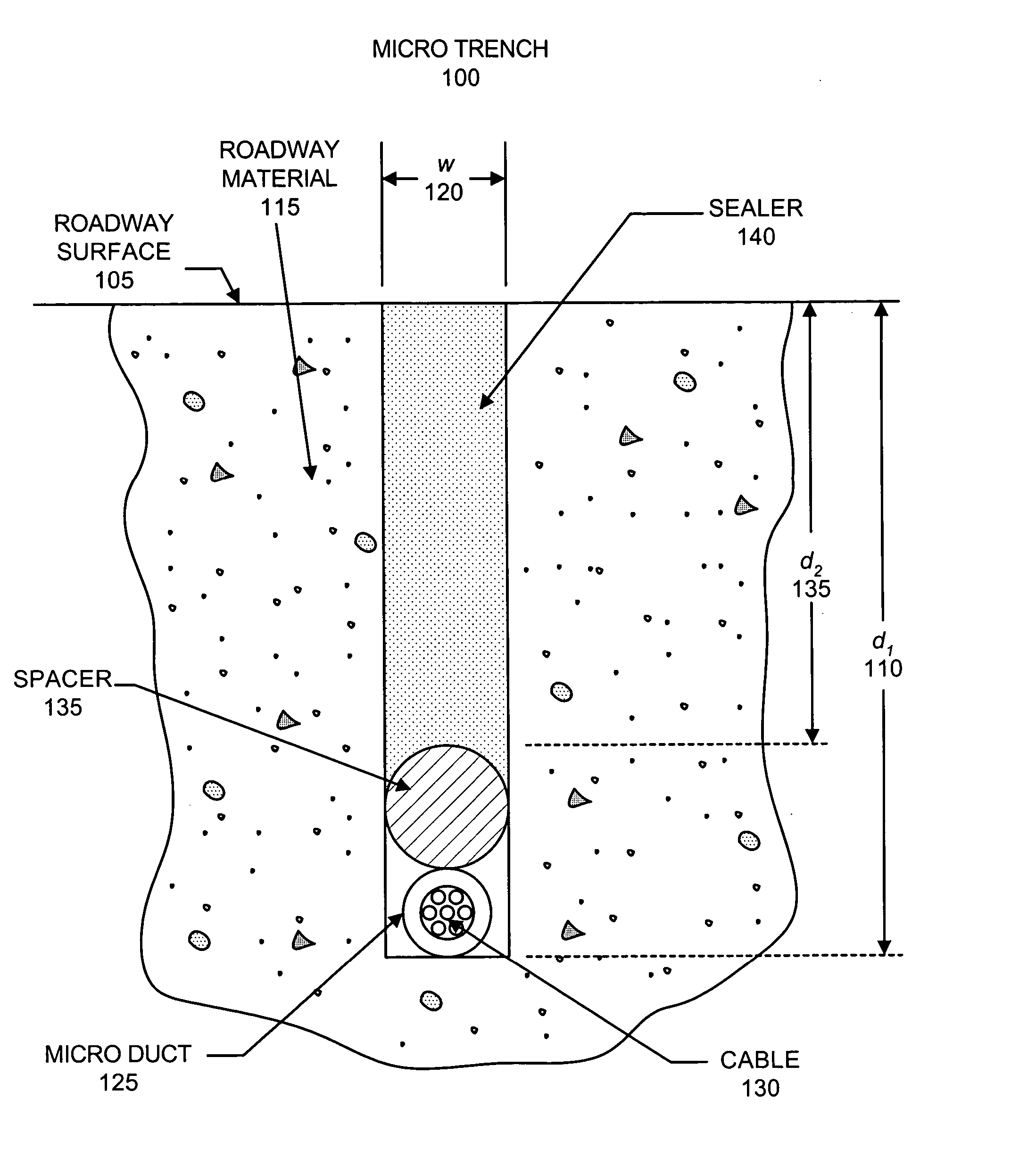

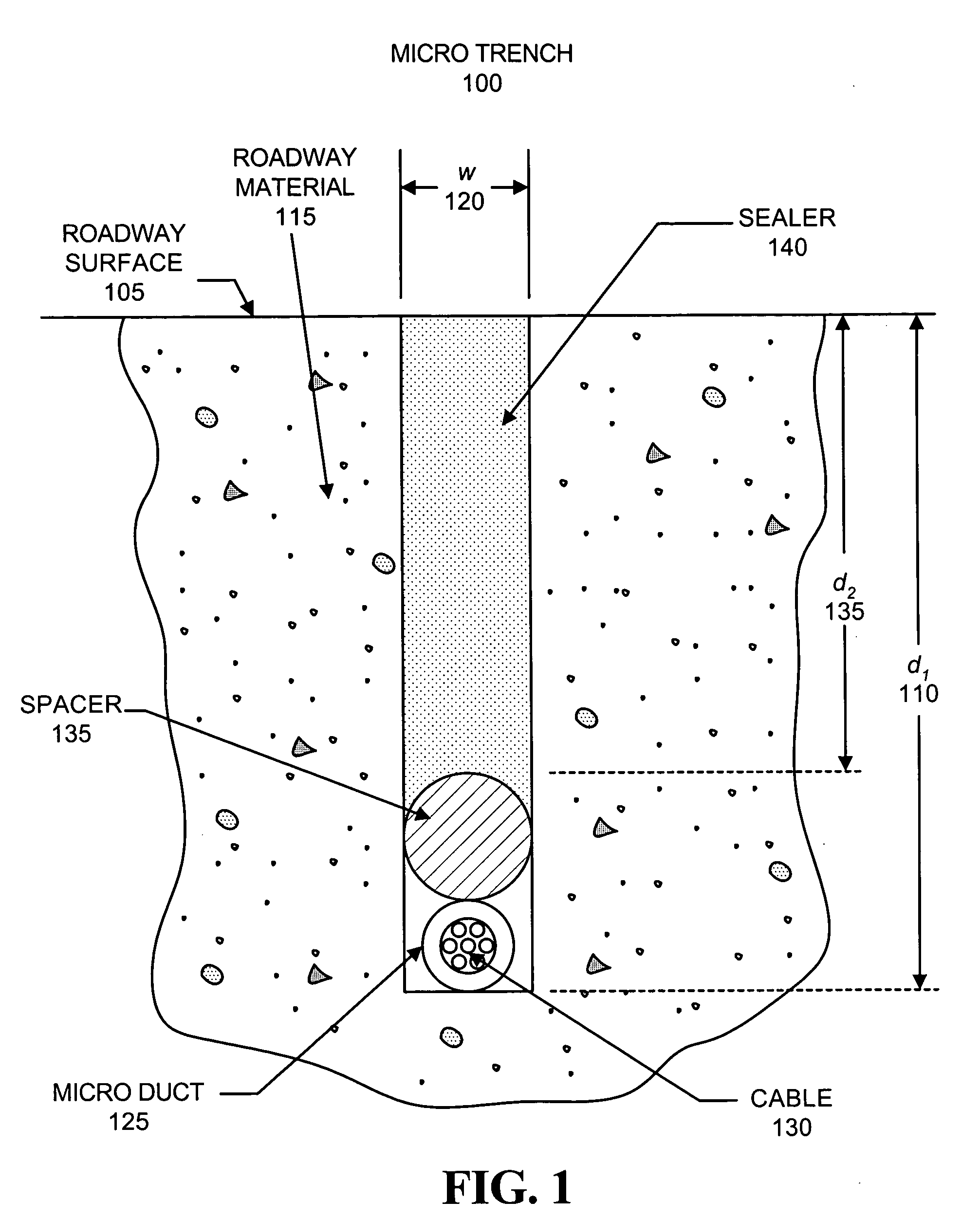

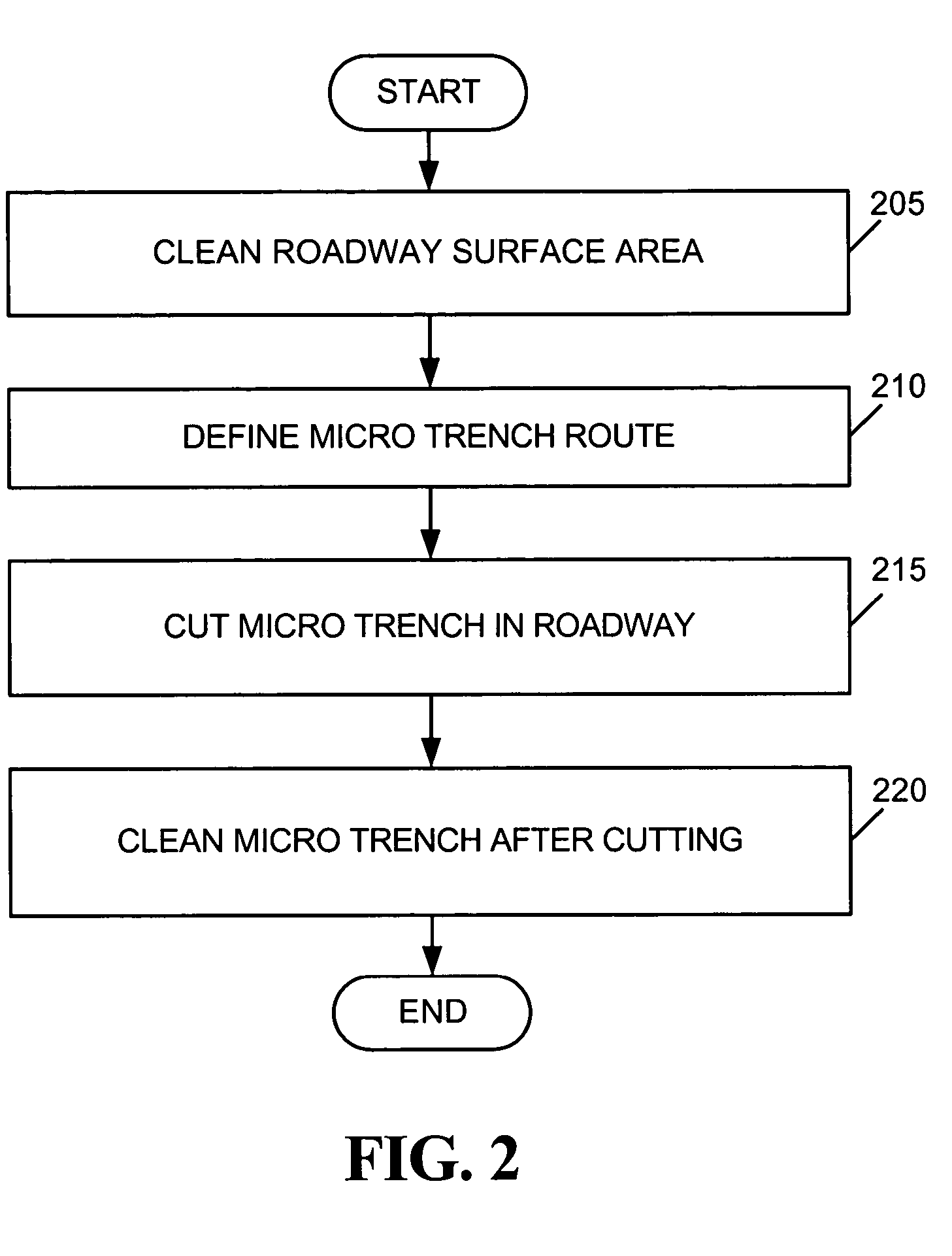

[0020] Methods and assemblies consistent with the present invention enable the placement of subsurface utility cables through the use of subsurface micro trenches and micro ducts, installed in roadway concrete or asphalt, that require minimal surface trenching, permit easy repair of the utility cables, and protect the utility cables from environmental conditions or external events. Consistent with one aspect of the invention, micro trenches may be cut approximately three to four inches into a roadway surface, and a micro duct that includes a high load rating material may be placed into the micro trench for carrying the subsurface utility...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com