Dosing body with an external base covering, method and device for applying the base covering

a technology of base covering and dosing body, applied in the field of can bodies, can solve the problems of affecting the design possibility of the can wall, and achieve the effect of simplifying the manufacturing result of cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

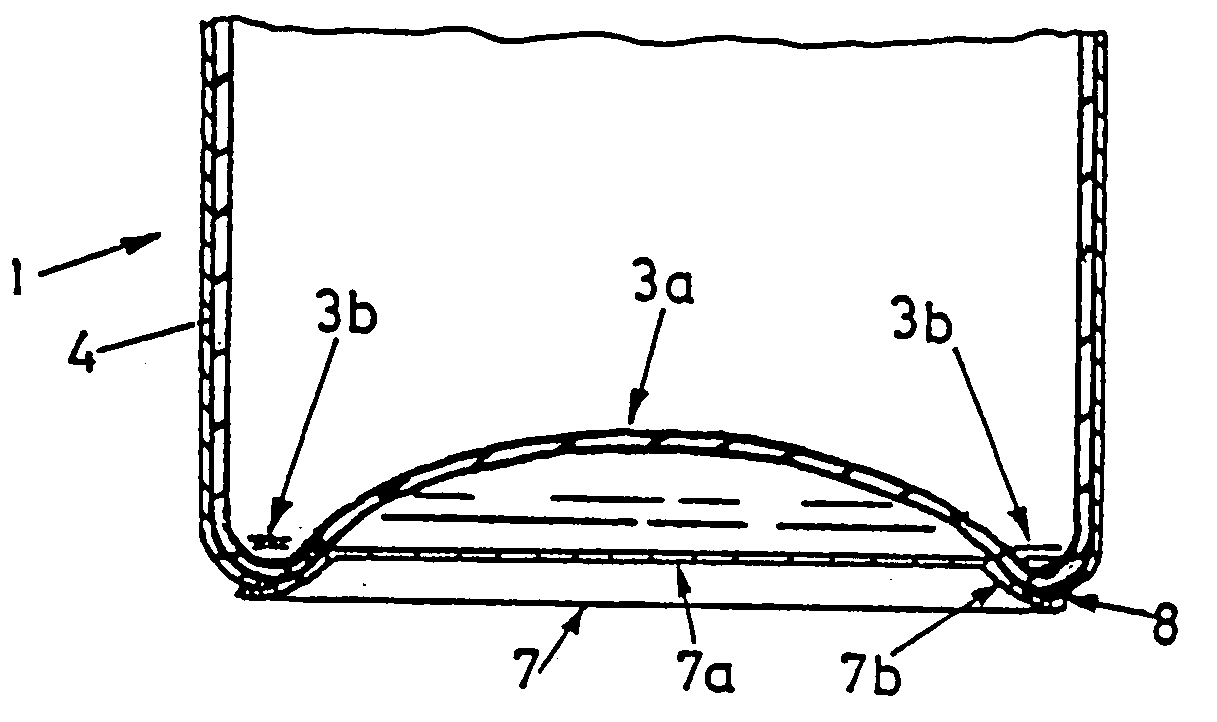

[0045]FIG. 1 illustrates a can body 1 in accordance with the state of the art with a jacket-like closed can wall 2 and a base 3 on the lower end face of the can wall 2. This is an aerosol can whose base 3 is arched with a central region 3a against the can interior. A downwardly projecting annular edge region 3b is formed around the central region 3a. The cans stand on a support line of the annular edge region 3b wherein the support line can be weakened by corrosion so that the central region 3a can break out. The can wall and the base include a metal layer 5. A decorative layer 4 is arranged on the exterior of the can wall 2 or at the metal layer 5 that extends from a valve seat 6 through a conified neck and the predominant region of the can wall 2 up to the transition wall from the can wall 2 to the base 3. An uncoated can region is visible beneath the lower edging of the decorative layer 4.

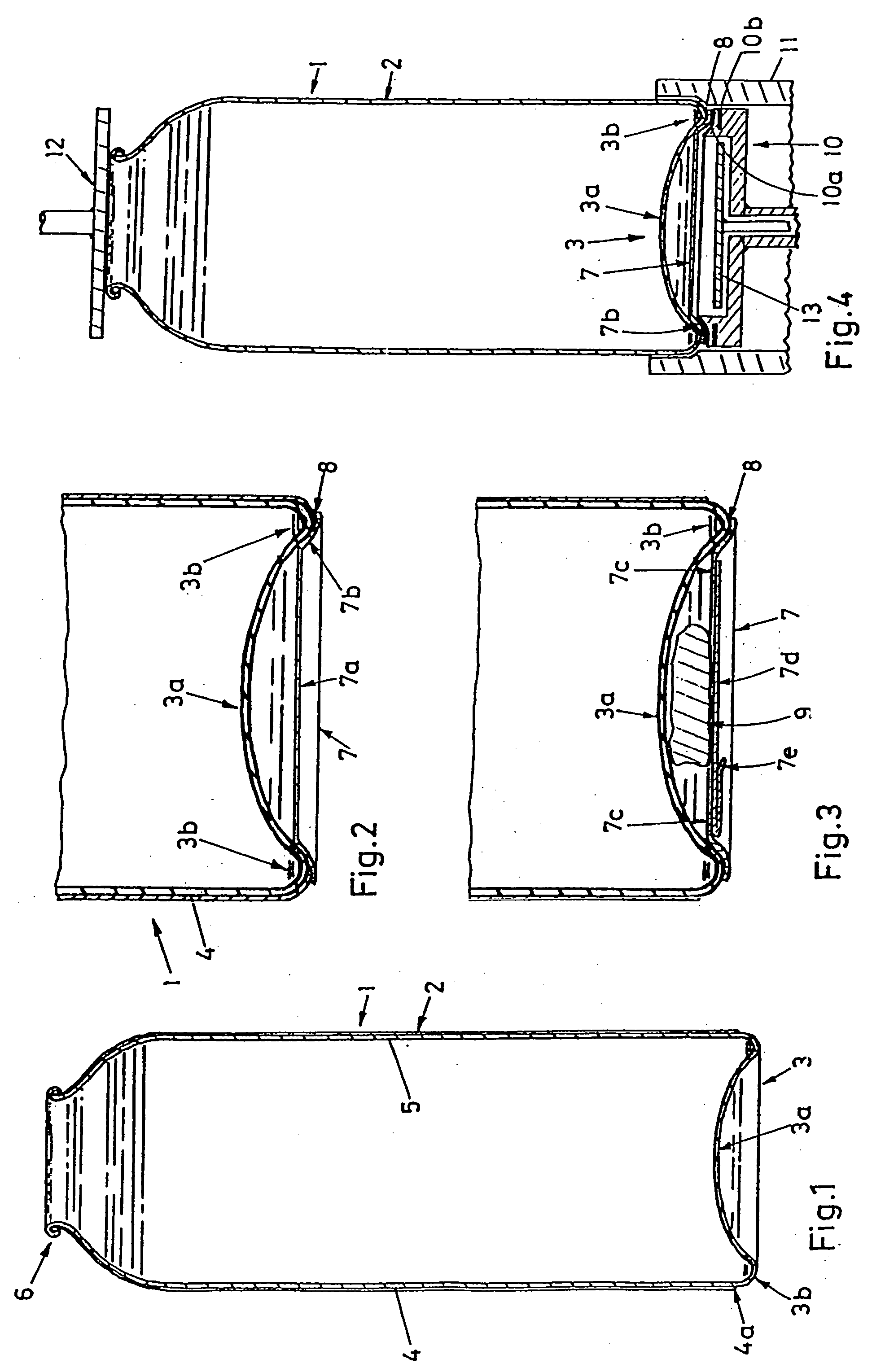

[0046]FIG. 2 shows a preferred embodiment of an aerosol can 1 with an external base coverin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com