Flat-sided funnel

a funnel and flat-sided technology, applied in the field of funnels, can solve the problems of inability to adapt to the design of singletons made from inexpensive materials and fail to roll well, and the mouth of empty bags tends to collapse, etc., and achieves the effect of convenient storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

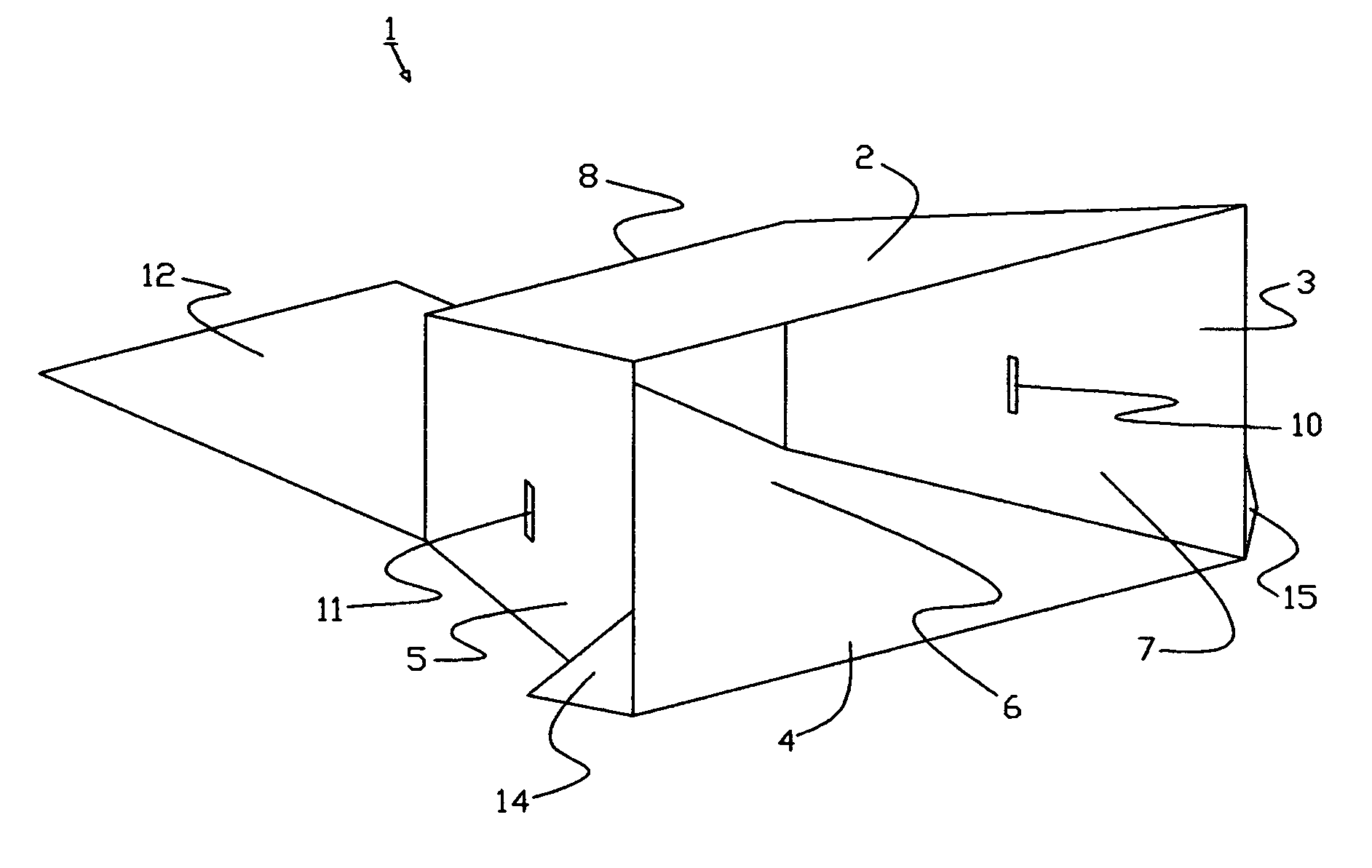

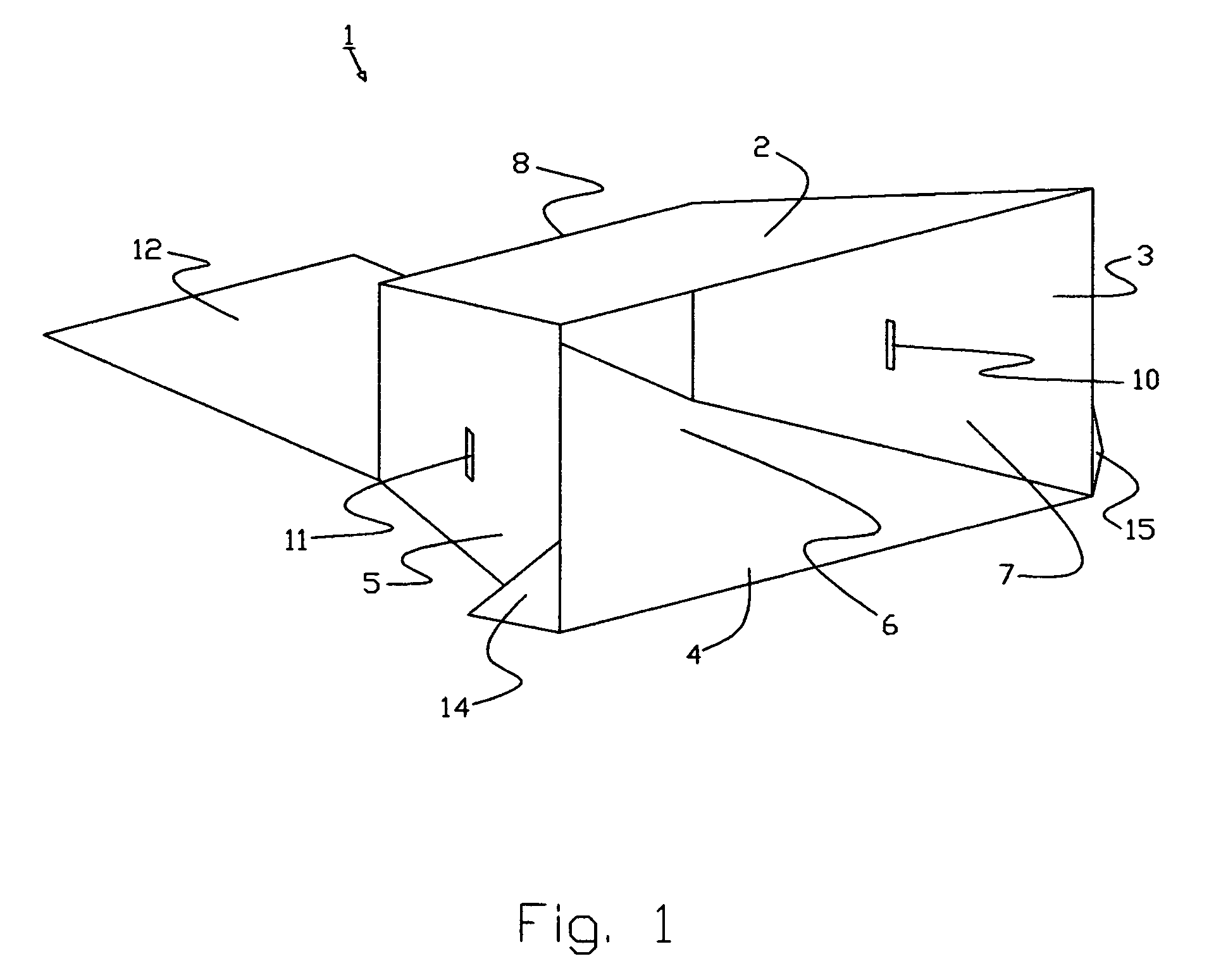

[0022]FIG. 1 shows a funnel according to an embodiment of the invention.

[0023] Briefly, a funnel according to an embodiment of the invention includes at least four flat sides that form a passage with a first opening and a second opening. The first opening is wider and taller than the second opening. At least one of the four flat sides includes one or more slots for attaching a bag such as a leaf bag.

[0024] Thus, FIG. 1 shows funnel 1 with sides 2, 3, 4 and 5 that form passage 6. This passage has first opening 7 and second opening 8. The first opening is wider and taller than the second opening. Sides 3 and 5 include slots 10 and 11 for attaching a bag (not shown) such as a leaf bag. The bag can be attached using any suitable technique or device, including but not limited to tape, clips, pins, and the like.

[0025] In a preferred embodiment, openings 7 and 8 are perpendicular to at least one of the four flat sides. In FIG. 1, this side is side 4. In more exact geometric terms, a fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| durable | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com