Nail gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

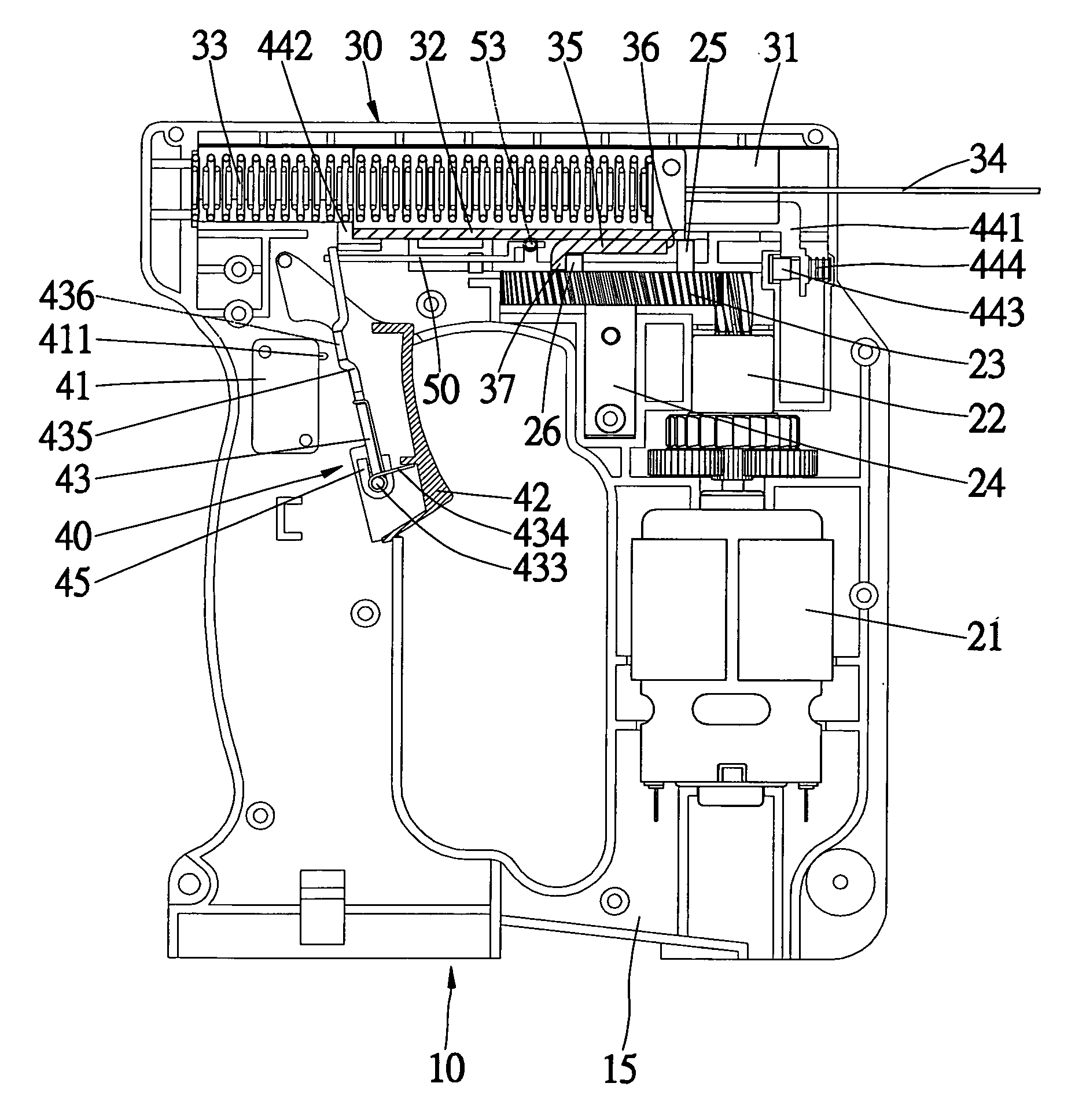

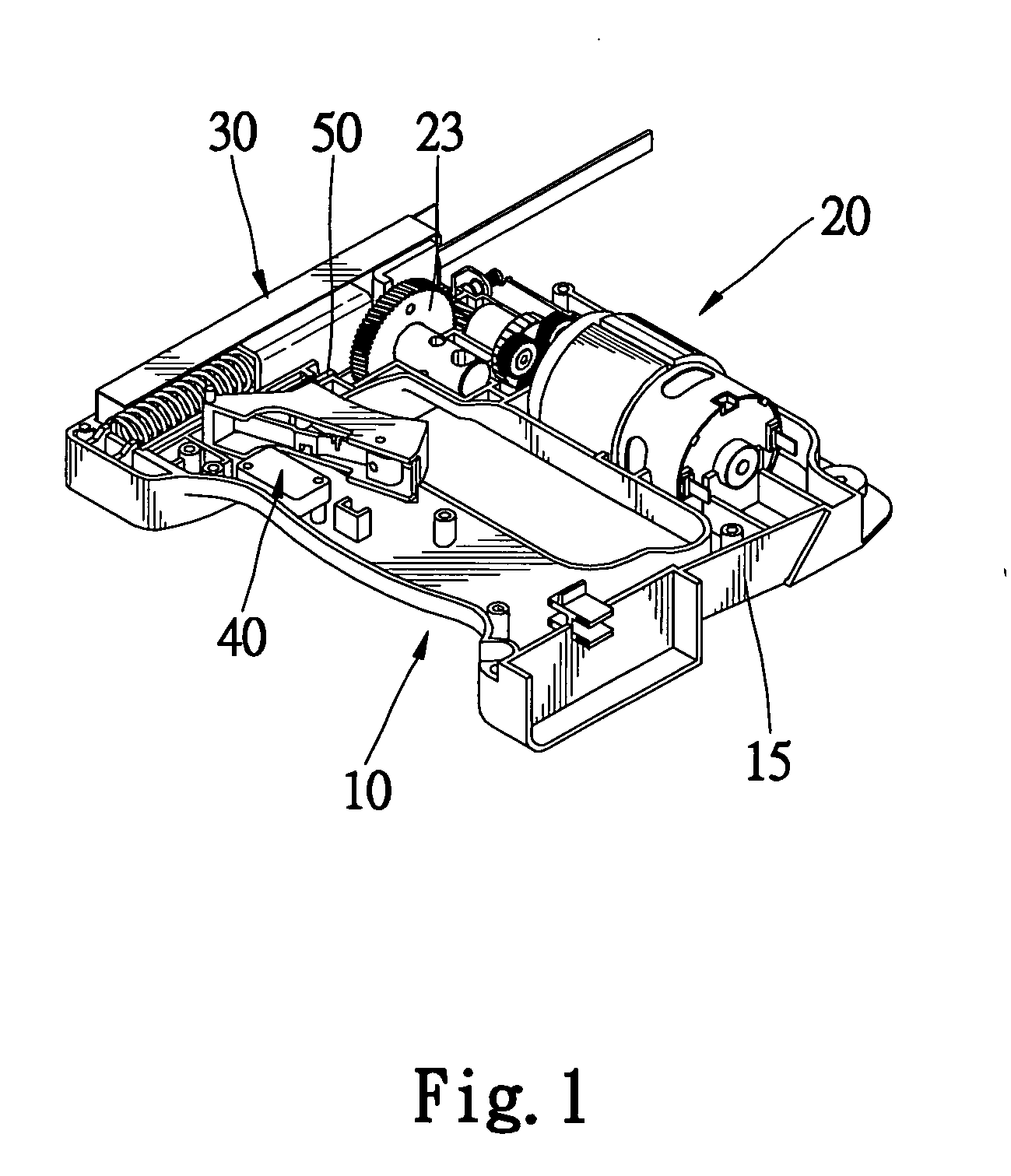

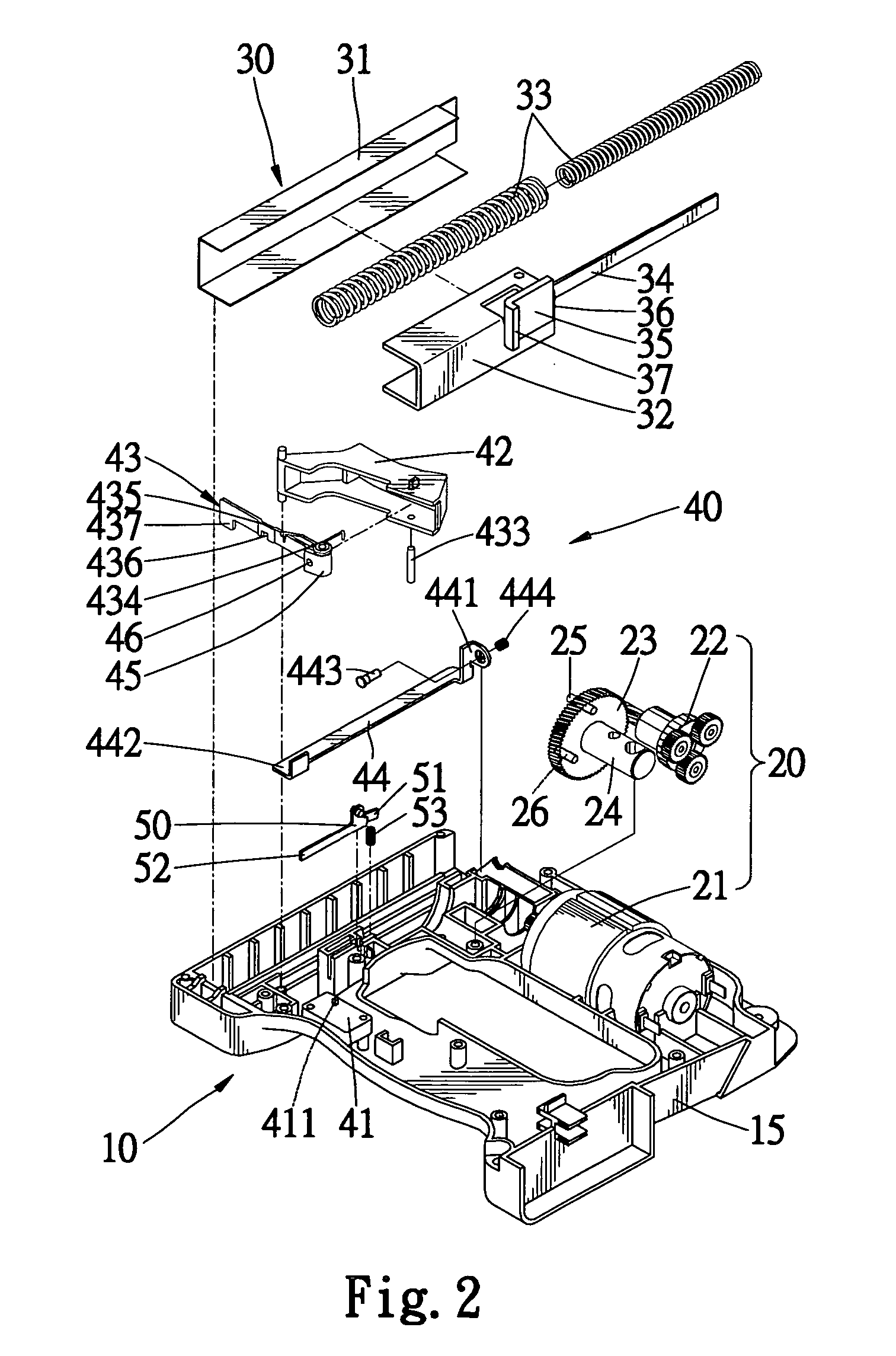

[0023] Referring to FIG. 1, a nail gun 10 includes a shell 15, a hammering device 30 for hammering nails, an energizing device 20 for providing energy to the hammering device 30, an actuating device 40 for actuating the energizing device 20 and a lever 50 for disabling the actuating device 40 after a nail is fired. The actuating device 50 can be reset in order to allow the firing of one more nail.

[0024] Referring to FIGS. 2 and 3, the energizing device 20 includes a motor 21 installed in the shell 15, a transmission 22 connected with the motor 21, a gear 23 connected with the transmission 22, and a shaft 24 for installing the gear 23 rotationally in the shell 15. A short rod 26 and a long rod 25 extend from a side of the gear 23.

[0025] The hammering device 30 includes a trough 31 installed in the shell 15, a hammer 32 movable in the trough 31, a pusher 34 secured to the hammer 32 and two springs 33 compressed between a portion of the shell 15 and a portion of the hammer 32. A tab ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy | aaaaa | aaaaa |

| Compressibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com