Handrail System Stanchion

a technology of handrails and brackets, which is applied in the field of glass barrier systems and support members, can solve the problems of brittleness of vinyl wedges used to secure glass to posts, weakened posts, and brittle parts of glass wall products currently available on the mark

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

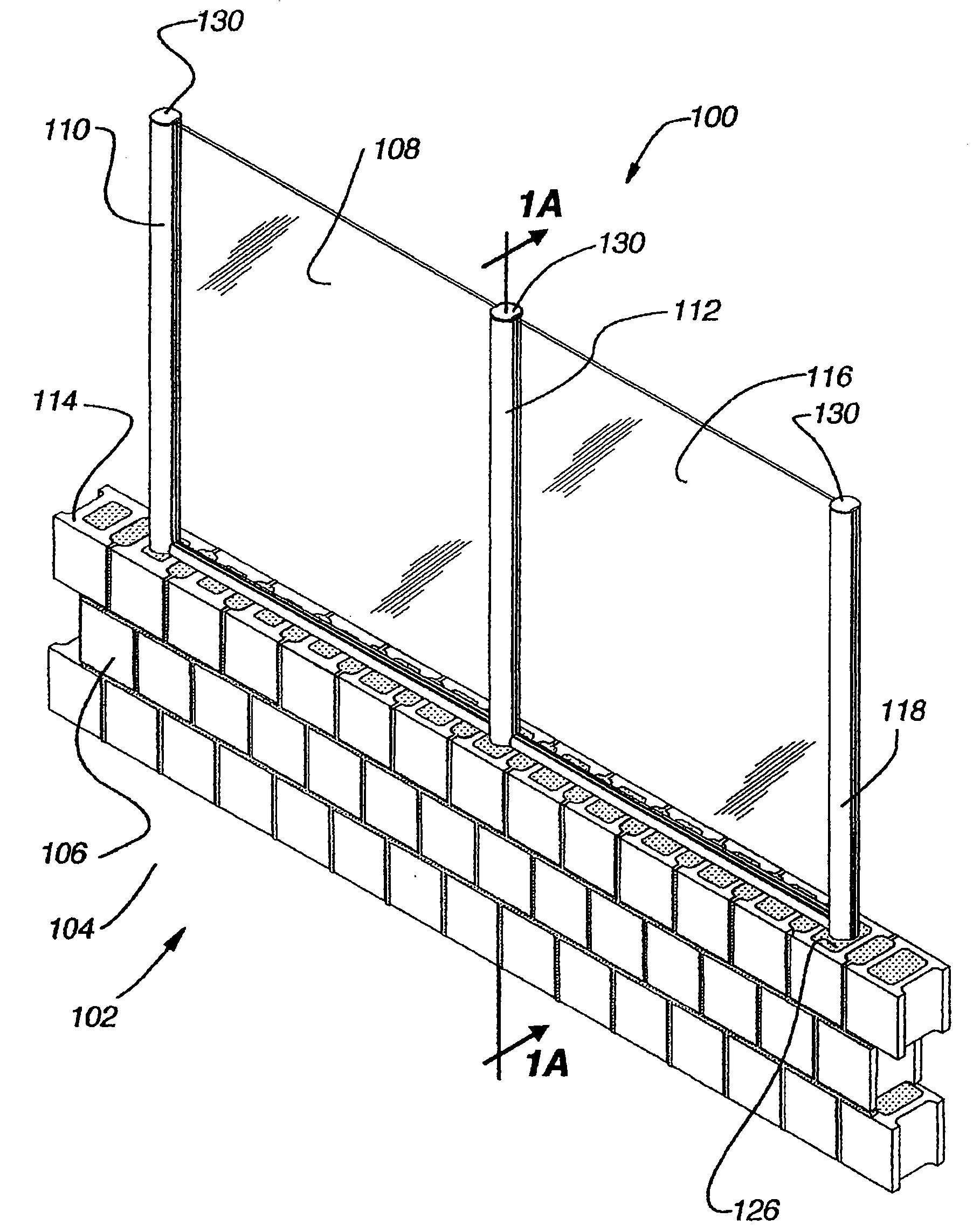

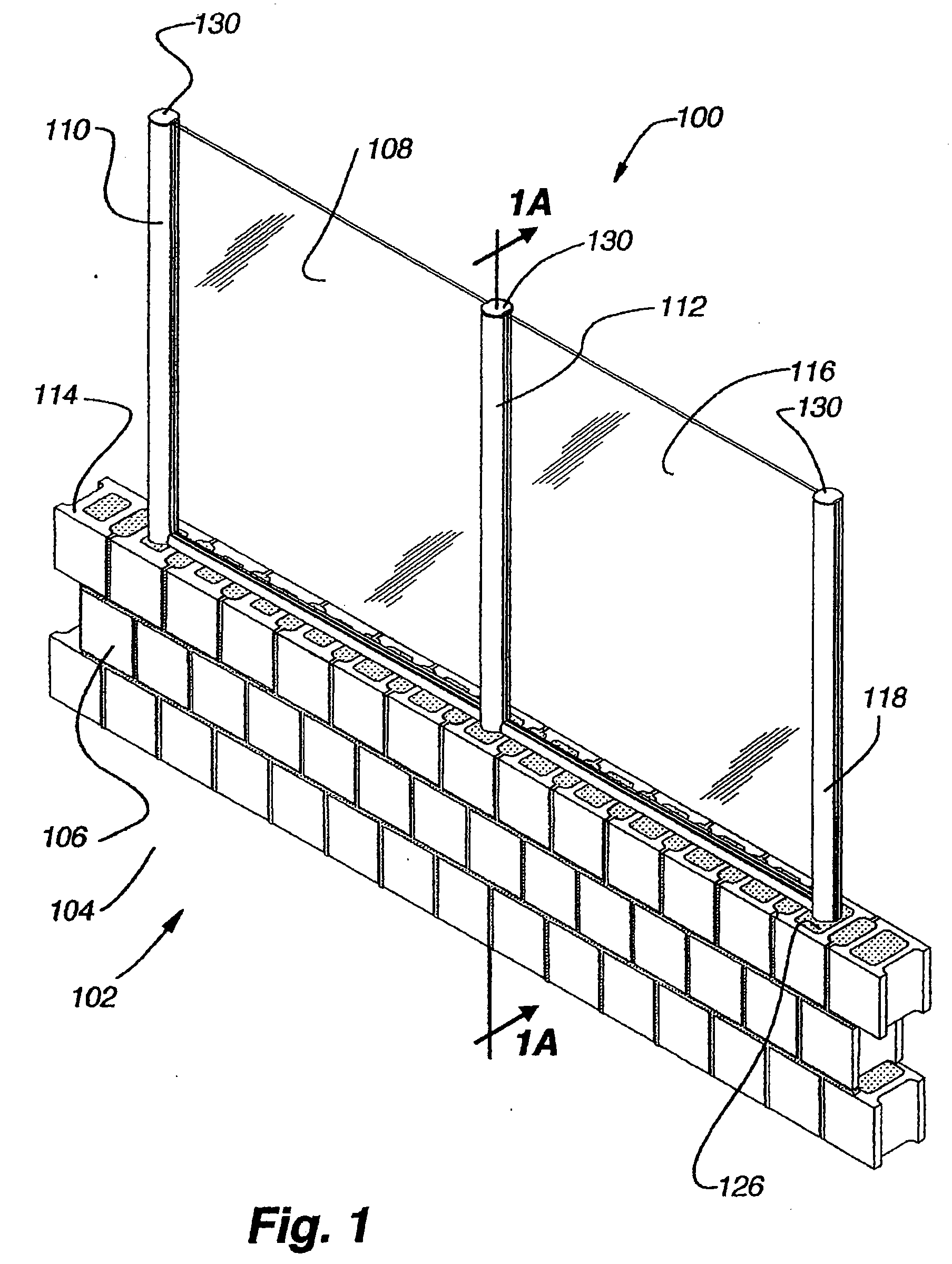

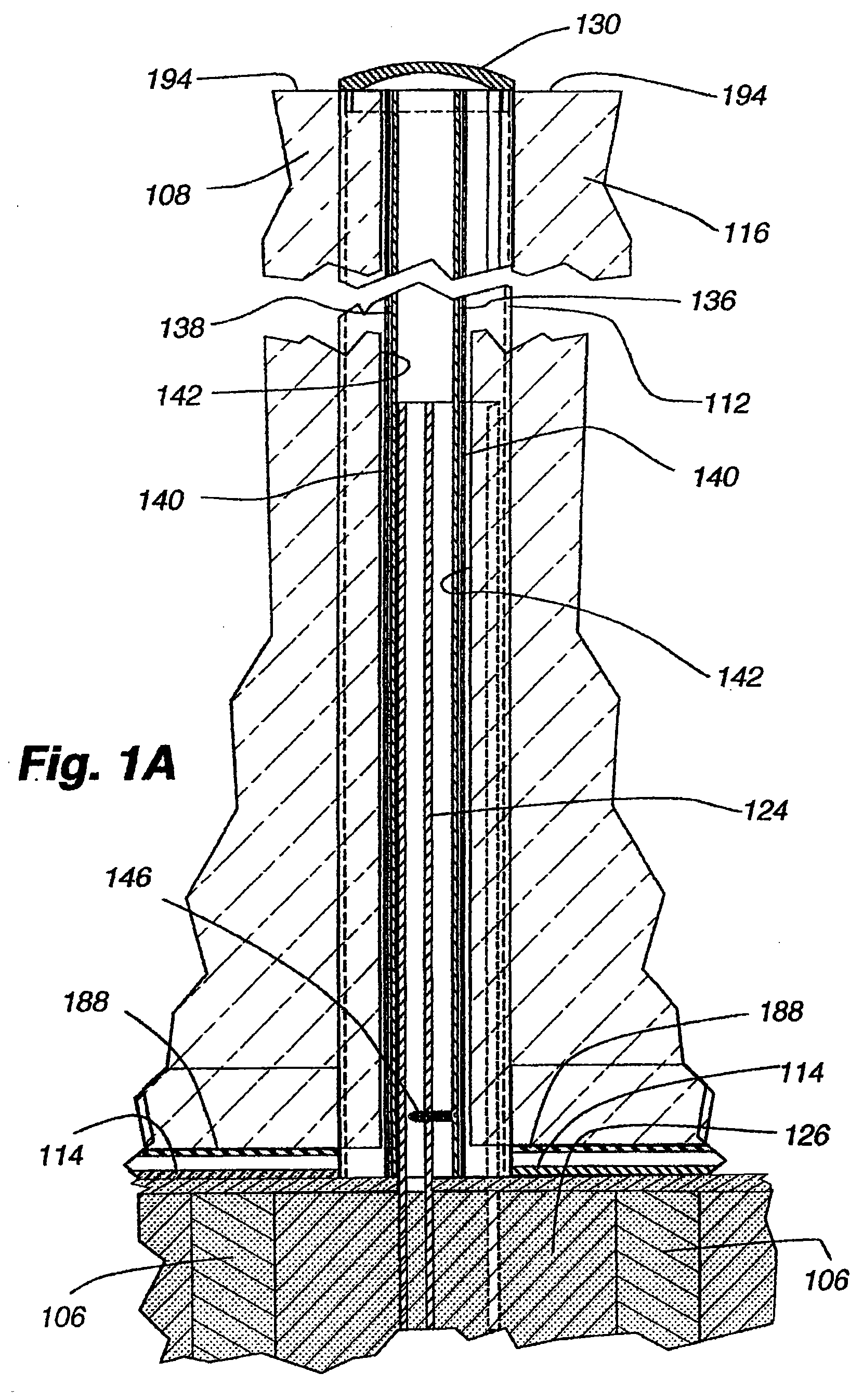

[0026] The present invention provides a glass barrier system constructed from pieces of glass supported between posts extending upward from various types of base structures, such as concrete slabs, masonry walls, and other similar structures. The posts are supported by support members connected with or embedded into the base structure. For example, in one embodiment of the glass support system, aluminum posts are supported by steel members embedded into and extending from a concrete base structure. By supporting the aluminum posts above the concrete, the glass barrier system can eliminate problems associated with lime in the concrete reacting with the aluminum posts. The glass barrier system according to the present invention can provide other benefits when installed as part of a larger construction project, such as a new building construction. For example, because the posts are not connected with or embedded directly into the base structure, the present invention allows the posts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com