Print media cartridge incorporating a power supply

a technology of power supply and print media, which is applied in the direction of printing, typewriters, other printing apparatuses, etc., can solve the problems of limiting the speed of printing or copying, limiting the speed of printing, and increasing the cost of providing the better performance to the manufacturer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

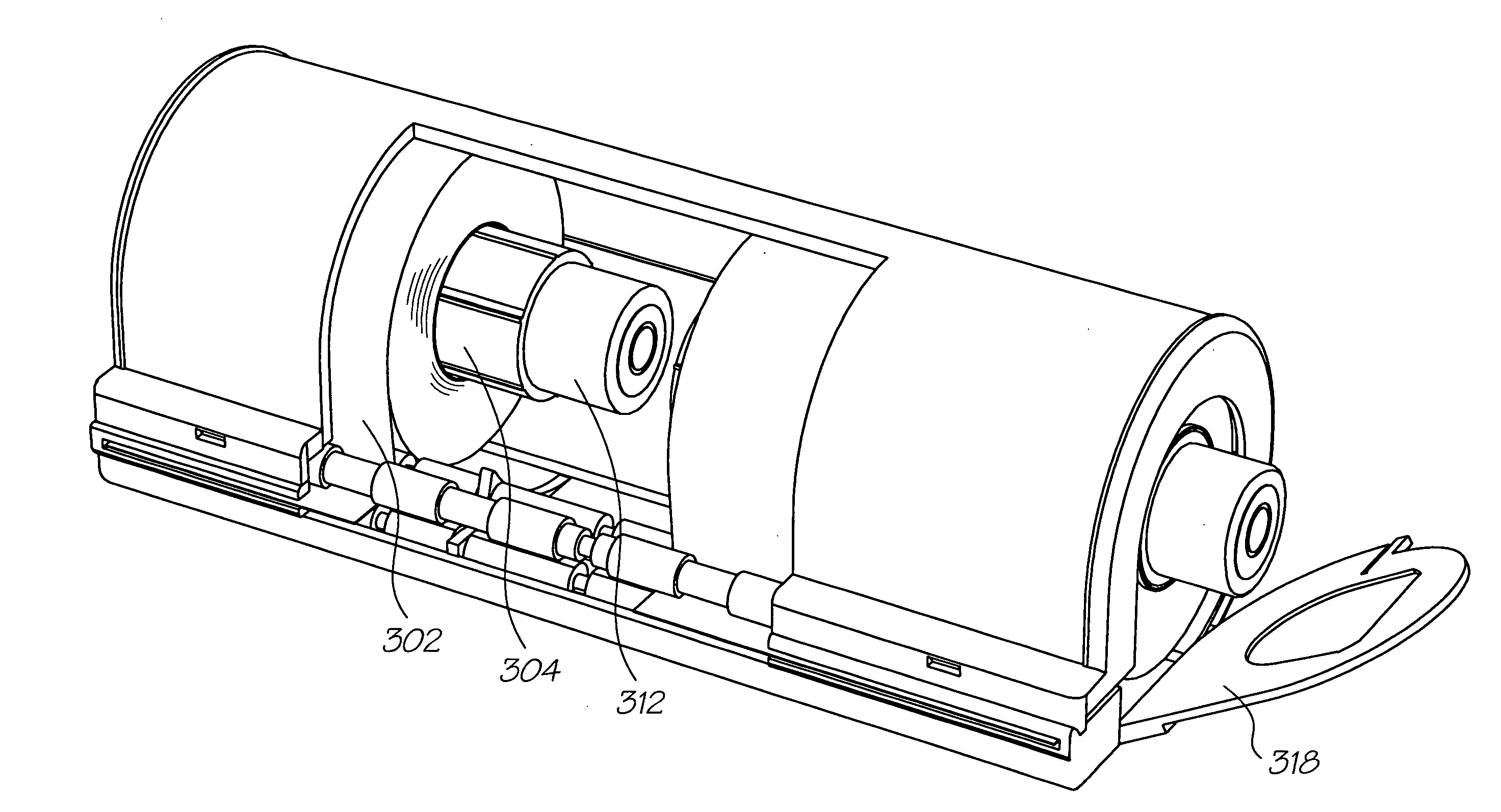

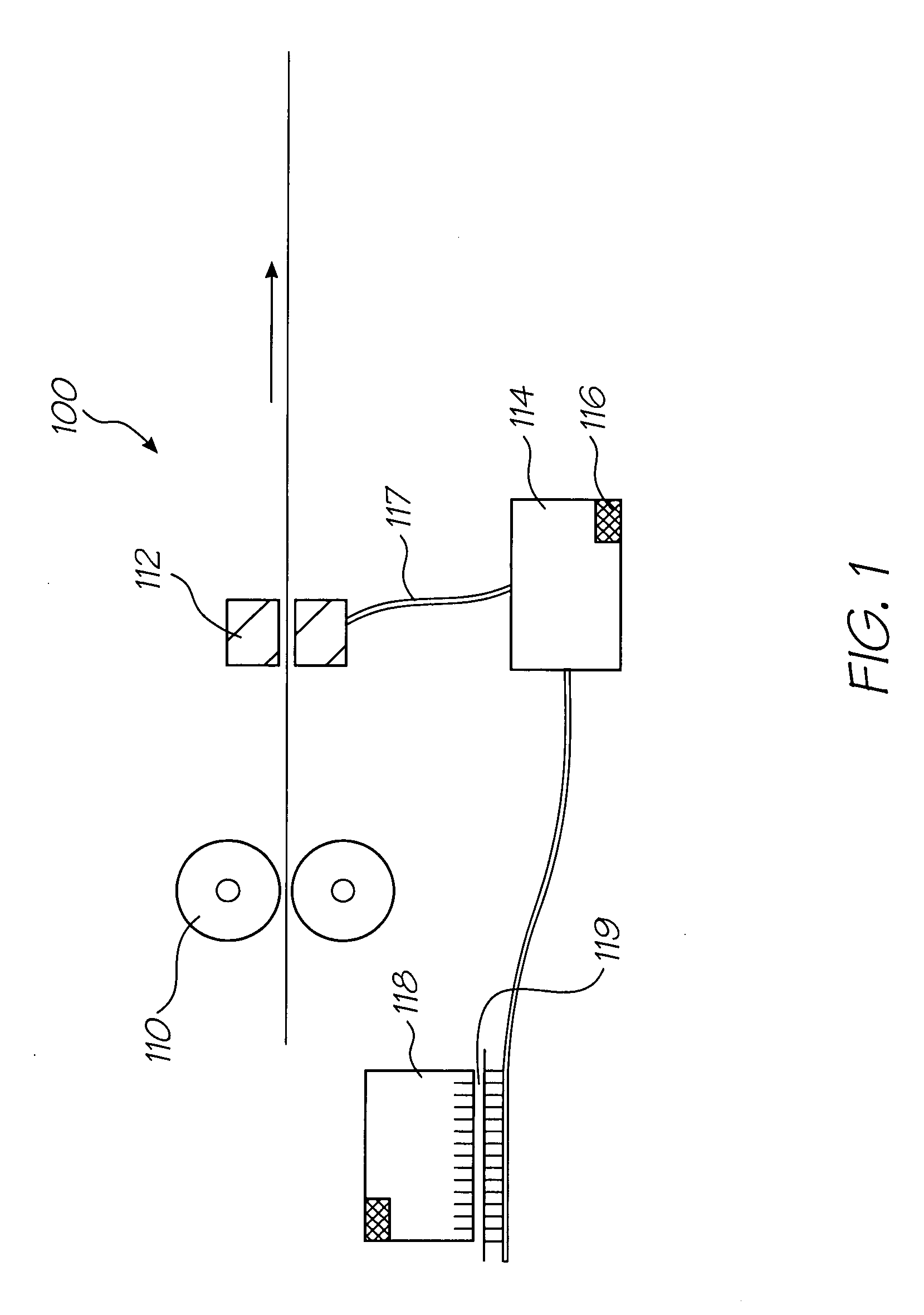

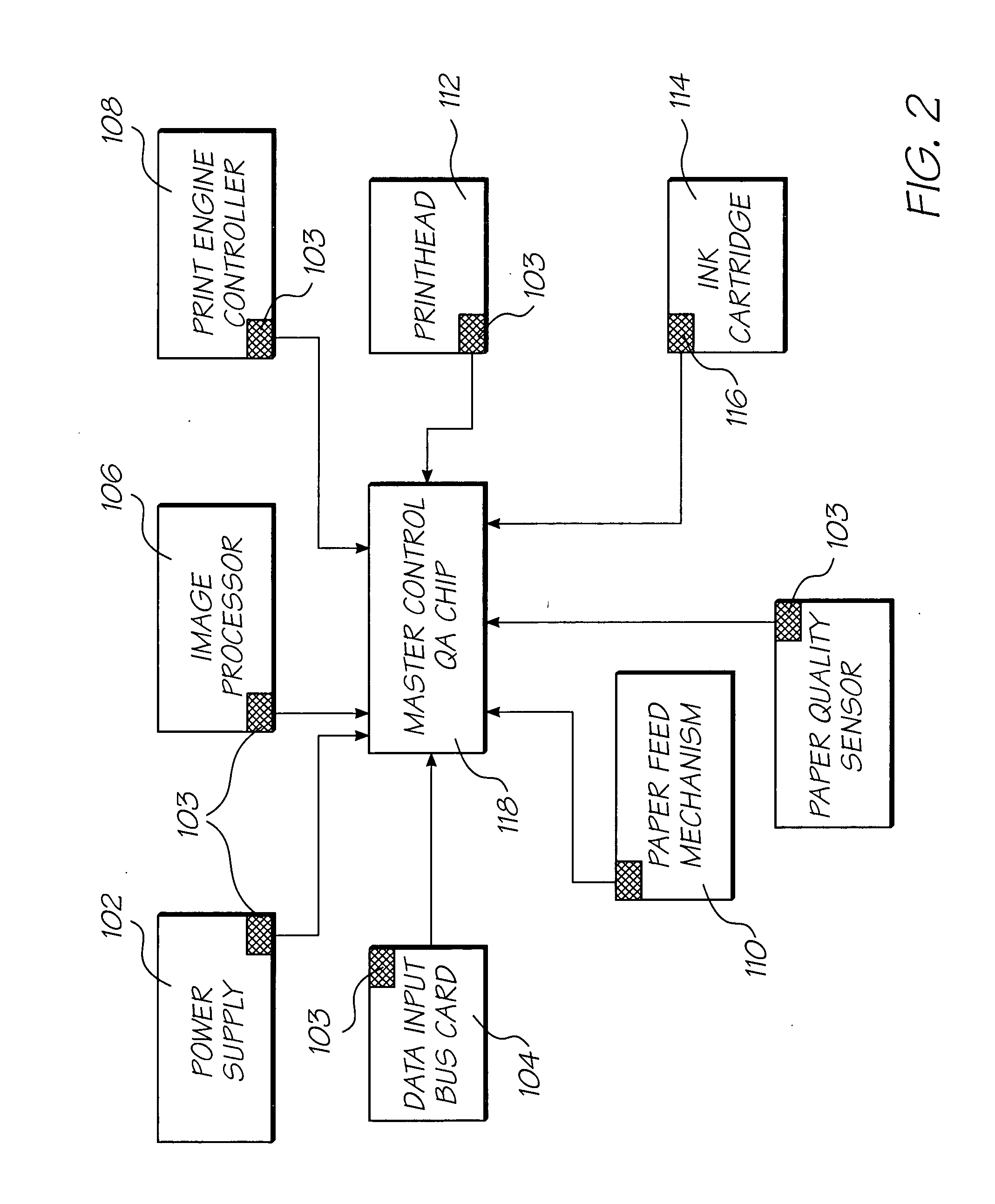

[0033] Referring to FIGS. 1 and 2 there are shown the major components of a typical ink jet printer 100. Typically an ink jet printer 100 has a power supply 102, a data input bus 104, an image processor 106, a print engine controller 108, a paper feed mechanism 110, a printhead 112 and an ink cartridge 114. The power supply 102 may be internal or external of the printer 100 and the printhead 112 and ink cartridge 114 may be separate units or combined in a single unit.

[0034] The performance of an ink jet printer is limited by a number of factors, including: [0035] 1) Image processor speed; [0036] 2) Data input bus speed; [0037] 3) Print engine controller speed; [0038] 4) Power supply; [0039] 5) Paper feed mechanism speed; [0040] 6) Printhead speed.

[0041] The printhead firing speed in turn is limited by: [0042] 1) Power consumption; [0043] 2) Heat dissipation; [0044] 3) Ink nozzle refill time; [0045] 4) Heat capacity of ink used.

[0046] The ink nozzle refill time is in turn limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com