Steam turbine exhaust diffuser

a technology of steam turbines and diffusers, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of loss and adverse pressure drop, and difficulty in bearing maintenance purposes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

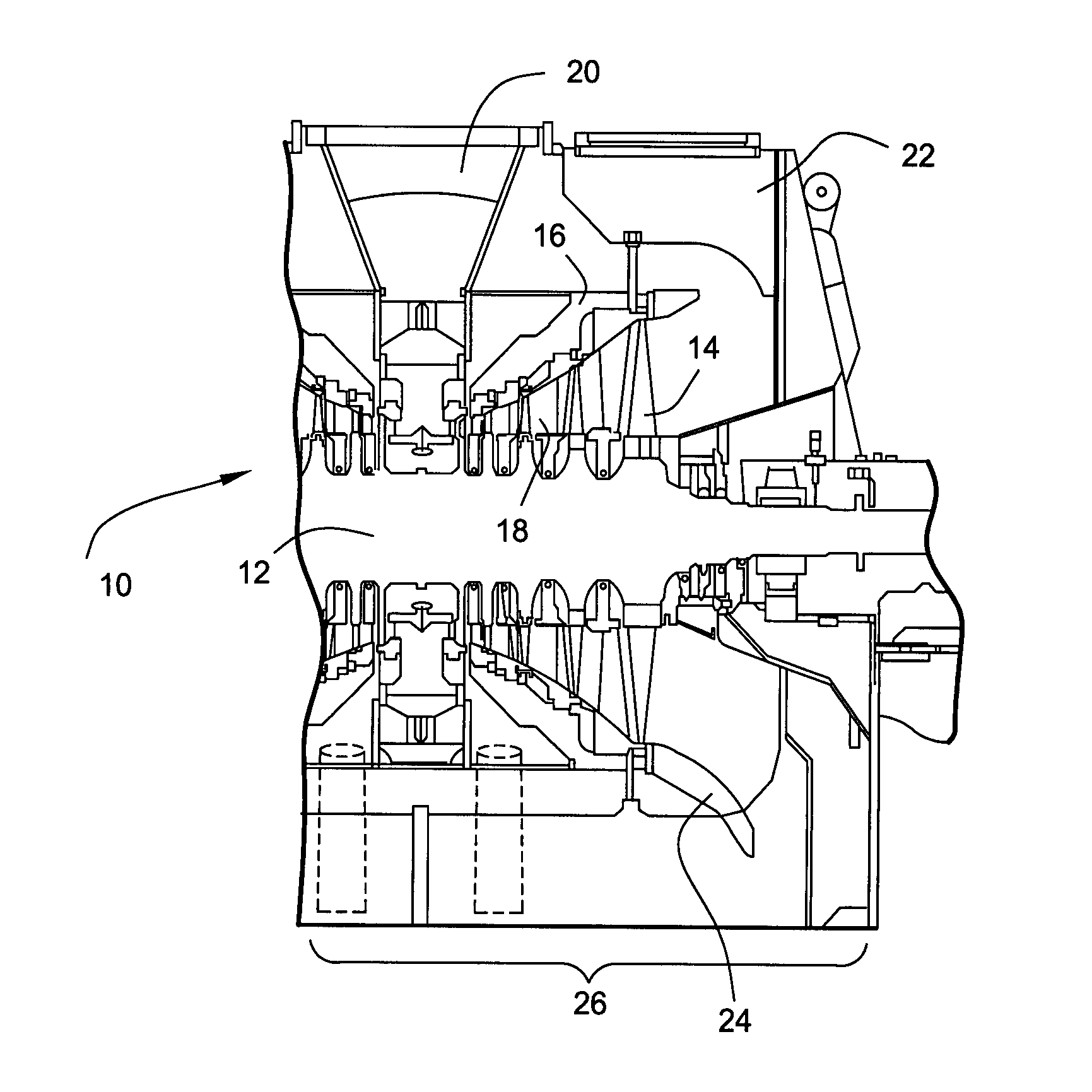

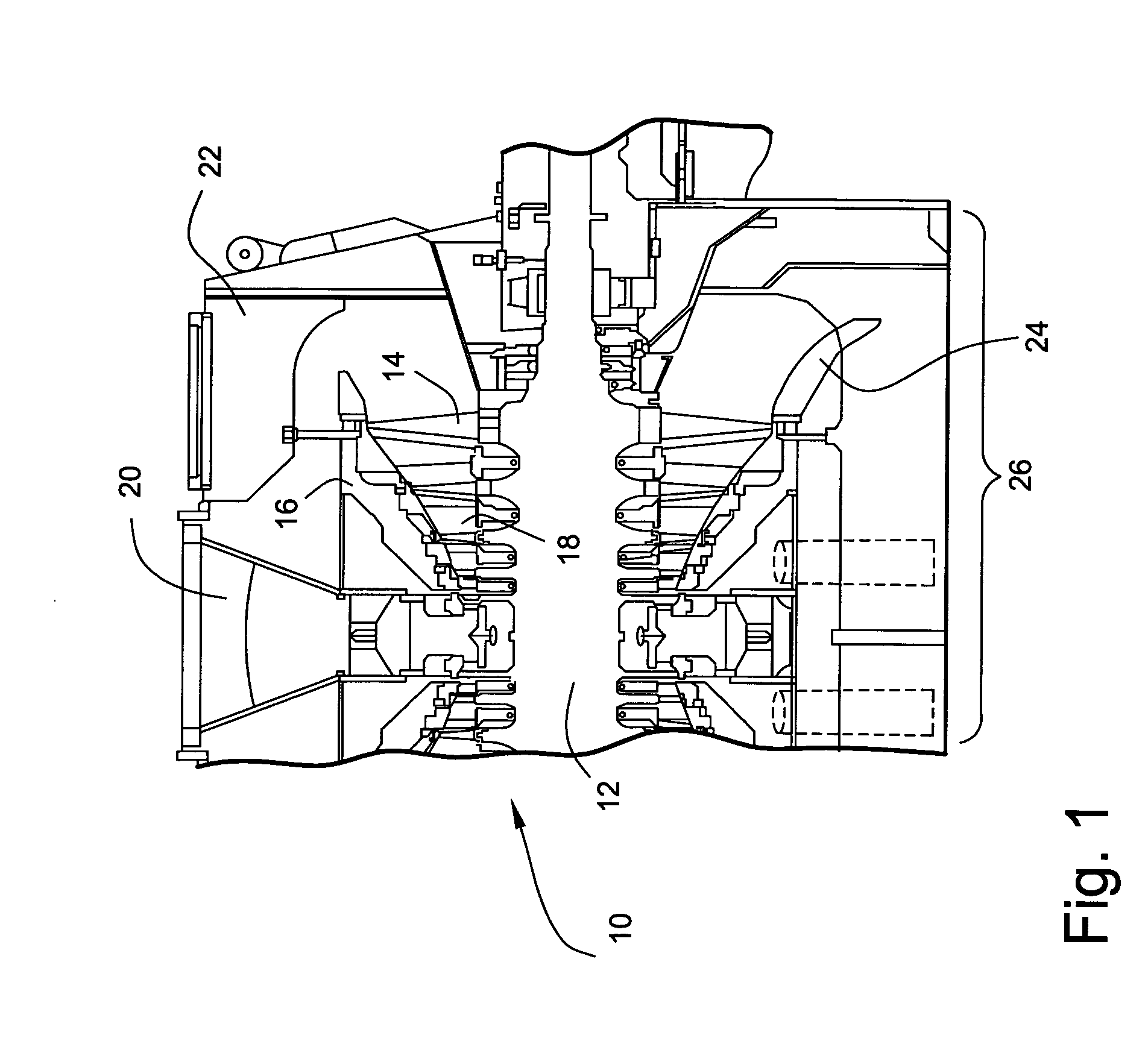

[0007] Referring now to the drawings, particularly to FIG. 1 there is illustrated a portion of a steam turbine, generally designated 10, including a rotor 12 mounting a plurality of turbine buckets 14. An inner casing 16 is also illustrated mounting a plurality of diaphragms 18. A centrally disposed generally radial steam inlet 20 applies steam to each of the turbine buckets and stator blades on opposite axial sides of the turbine to drive the rotor. The stator vanes of the diaphragms 18 and the axially adjacent buckets 14 form the various stages of the turbine forming a flow path and it will be appreciated that the steam is exhausted from the final stage of the turbine for flow into a condenser not shown.

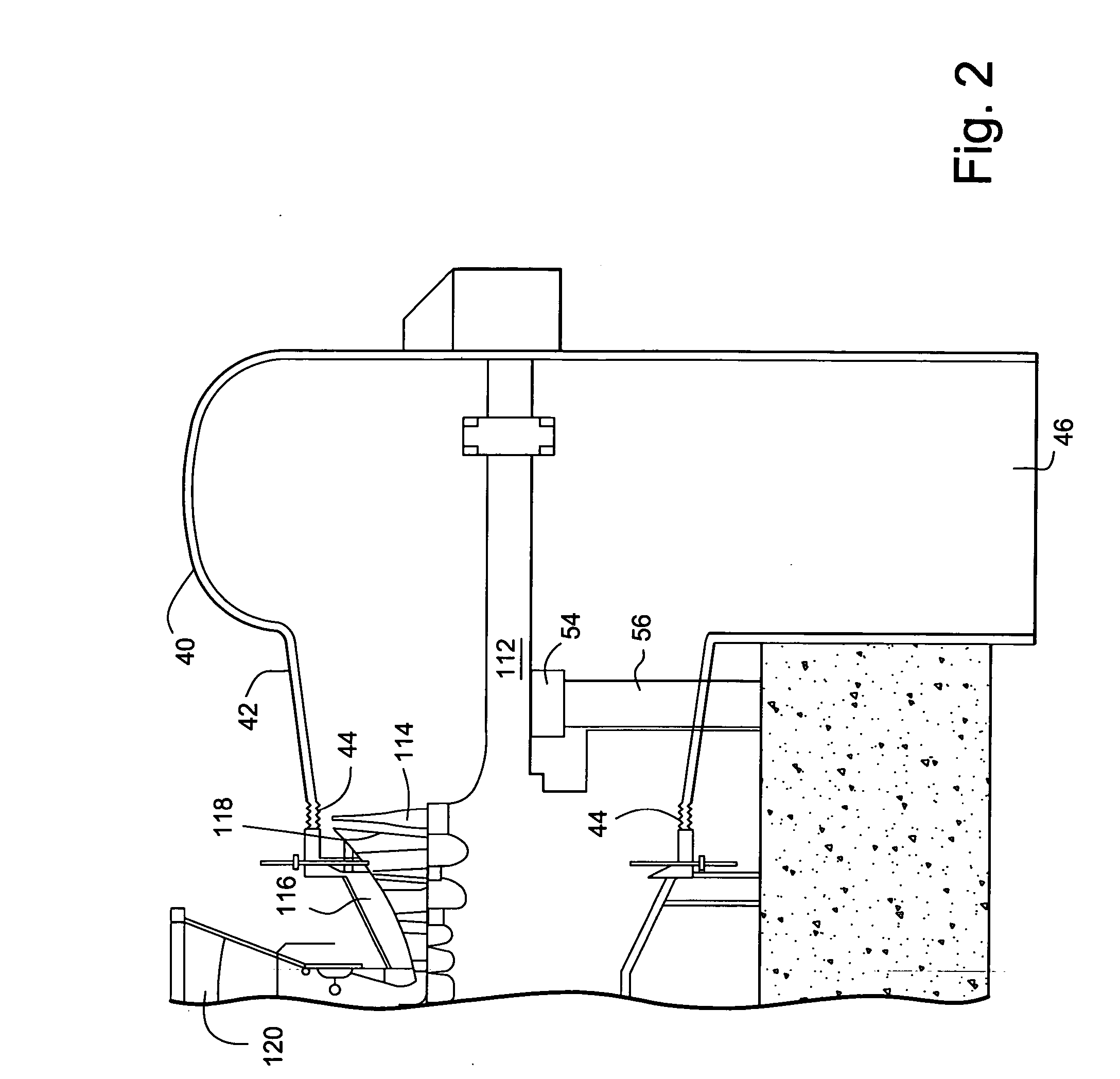

[0008] Also illustrated in FIG. 1 is an outer exhaust hood 22 which surrounds and supports the inner casing of the turbine as well as other parts such as the bearings. In the illustration of FIG. 1, the turbine includes steam guides 24 for guiding the steam exhausting from the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com