Dustpan with a latching mechanism

a technology of latching mechanism and dustpan, which is applied in the field of dustpans and dustpans, can solve the problems of more difficult making and repair, and achieve the effects of simplified construction and repair mode, less fatiguing the user, and simplified operation mod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

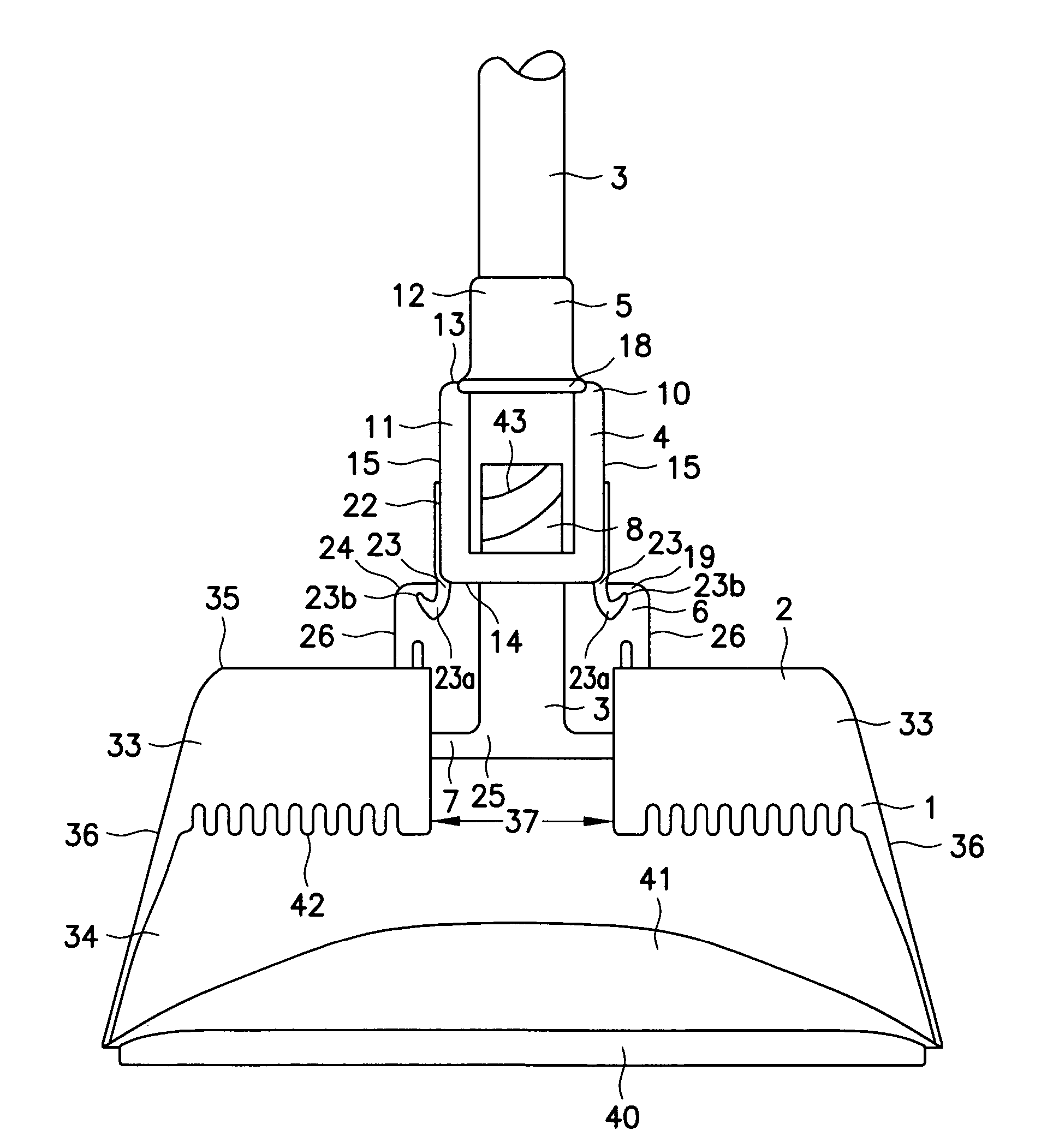

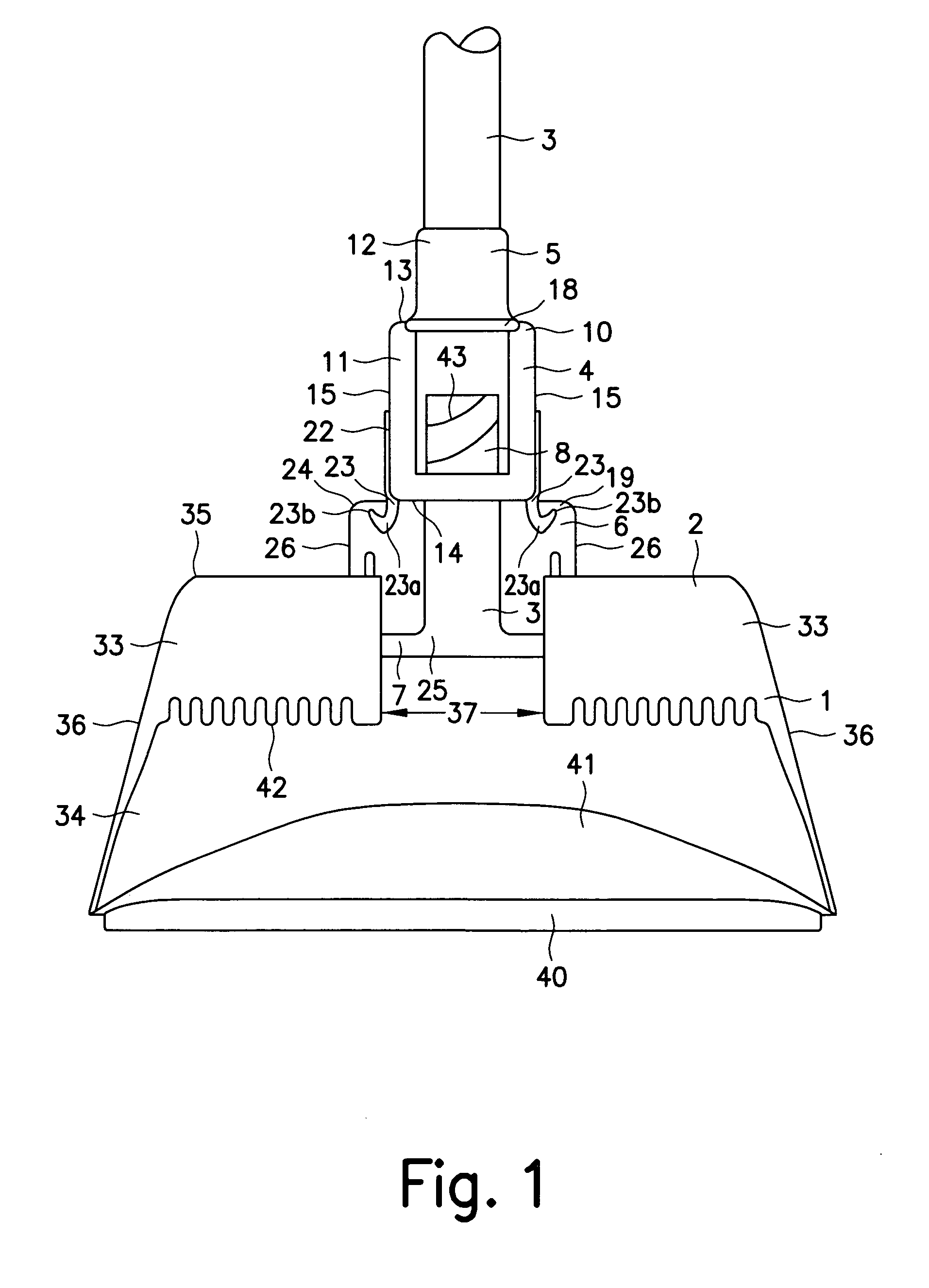

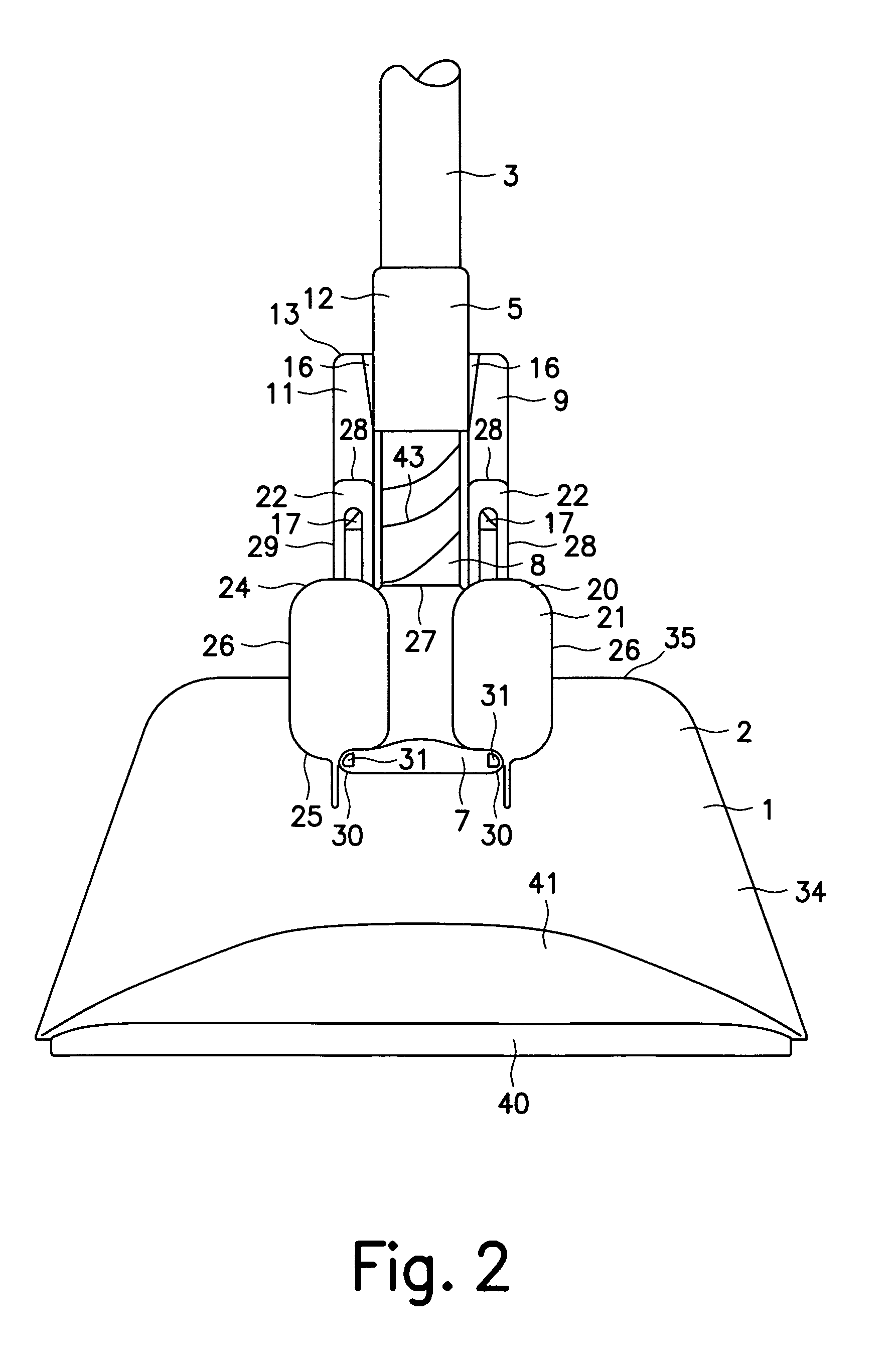

[0017] With reference to the drawings, in particular to FIGS. 1-8 thereof, the present invention, a dustpan with a novel latching mechanism, denoted by reference numeral 1 will be described. A dustpan 1 is shown comprising a dustpan receptacle 2, a handle 3 and a latching mechanism 4 consisting of two members: an upper latching member 5 and a lower latching member 6. The handle 3 is connected to the upper latching member 5 and the lower latching member 6. The dustpan receptacle 2 is connected to the lower latching member 6 by a pivotal connection 7. The upper latching member 5 and the lower latching member 6 are connected and interface each other. The handle 3 has a lower end 8 and an upper end 8a.

[0018] The upper latching member 5 has a first latching interface 9 (considered to be the front surface of the upper latching member 5) and a back surface 10 and consists of a plate 11, and an open ended hollow rod 12 for accepting a part of the handle 3. The plate 11 has a top edge 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com