Modular holster for handguns and the like

a modular, handgun technology, applied in the field of holsters, can solve the problems of increasing the cost of tooling for manufacture, requiring sizable inventories, and increasing the cost of manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

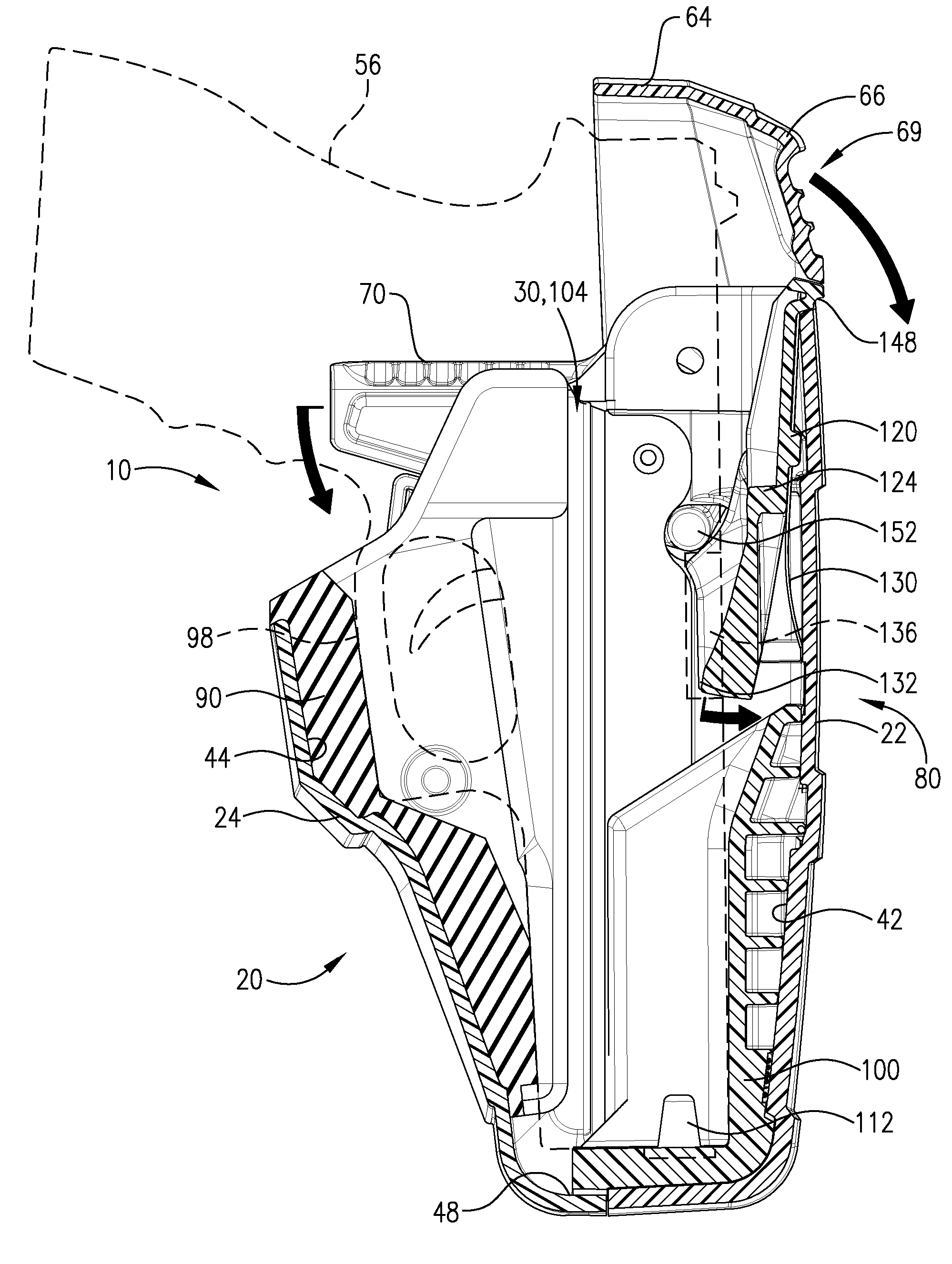

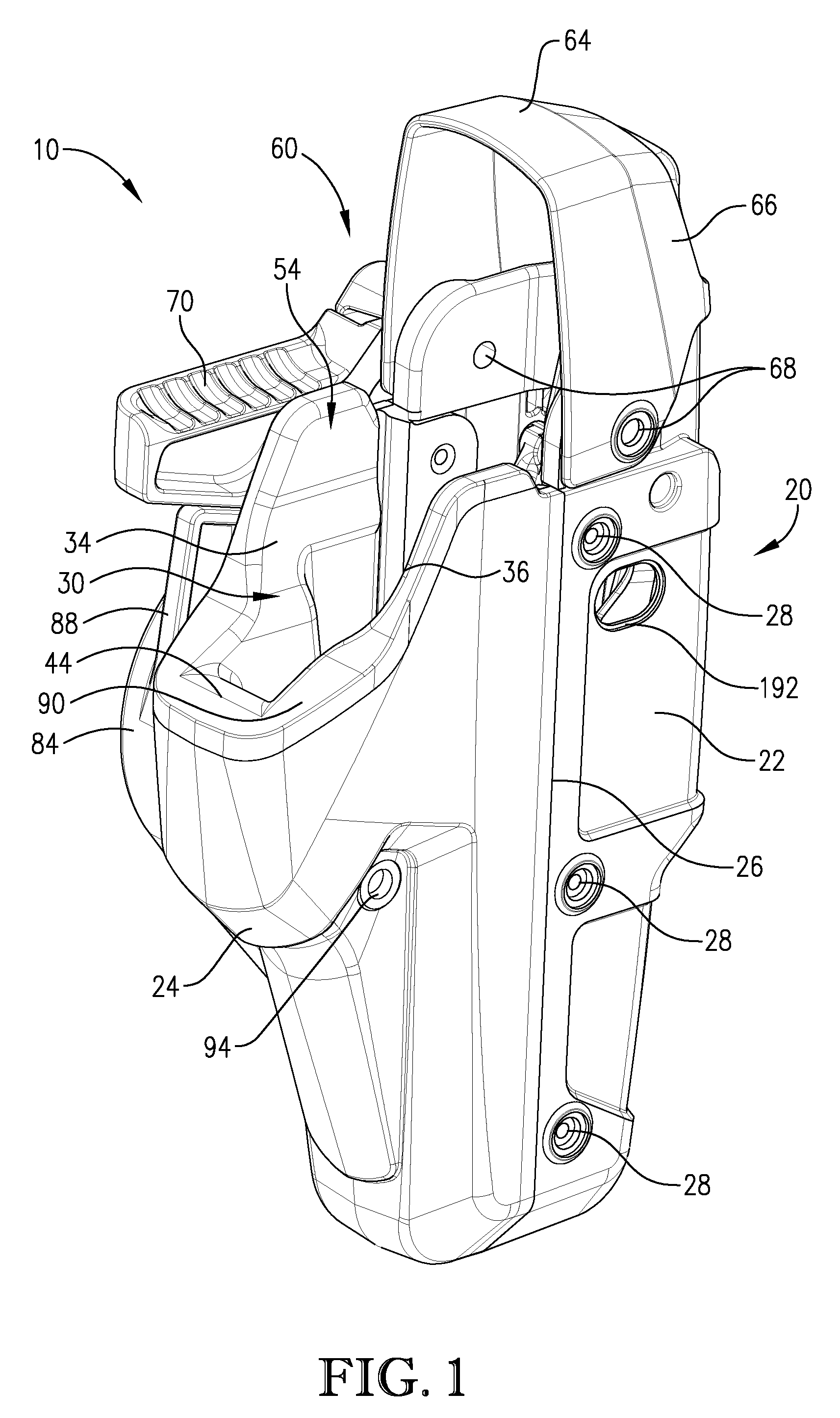

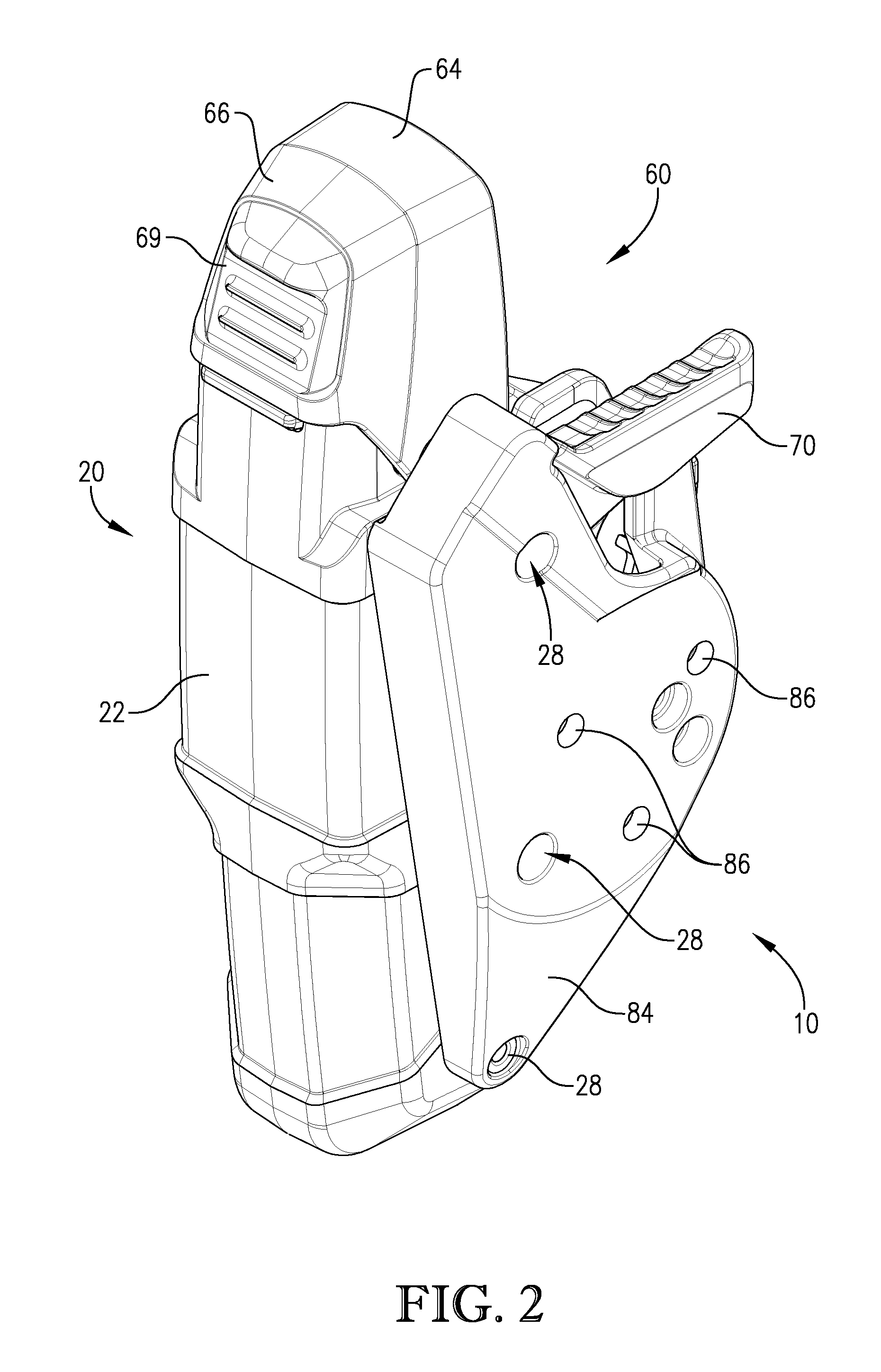

[0029] A holster incorporating principles of the present teachings is illustrated in FIG. 1 and designated generally by the reference numeral 10. The holster 10 includes a body 20 comprising a front shell 22 and a rear shell 24 coupled together to define a cavity 30. Front and rear shells 22, 24 may be coupled together along a longitudinal seam 26 where they overlap and are screwed together via rows of attachment holes 28 and screws (not shown) on the inner and outer sides of holster 10. Front and rear shells 22 and 24 cooperate to form opposing inner and outer side walls 34 and 36, respectively, of body 20. Body 20 further includes front and rear walls 42 (FIG. 11) and 44, respectively, and a floor 48 including a drain hole 50, as best shown in FIG. 8. Body 20 defines a top opening 54 sized to admit at least a portion of a handgun 56 (see FIGS. 11-12) into cavity 30. Cavity 30 may also include other openings, such as an open bottom. A substantially enclosed cavity, such as the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com