Hybrid cryocooler with multiple passive stages

a technology of cryocooler and passive stage, which is applied in the field of cryocooler, can solve the problems of inefficient thermodynamics, large size, and high cost of the approach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A multi-stage cryocooler has three or more stages, including an active first stage and passive second and third stages. The active stage may include a Stirling expander, and the passive second and third stages may be pulse tube coolers. The cryocooler may provide cooling at three different temperatures. The coldest cooling temperature may be at or below 10 K, and may be at or below 5 K. The system may provide cooling at such low temperatures while still operating at a relatively high frequency, for example, at a frequency of at least about 20 Hertz.

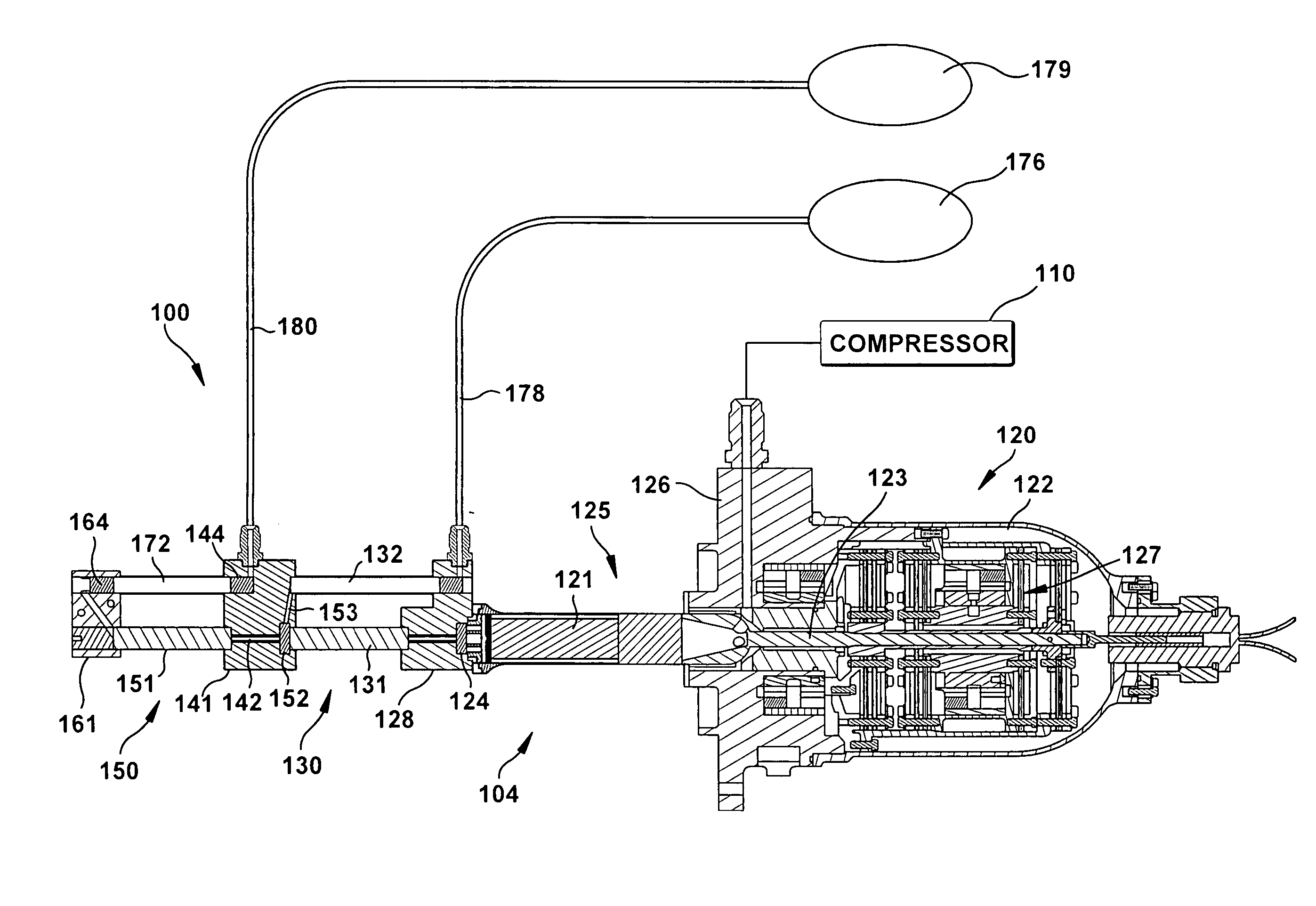

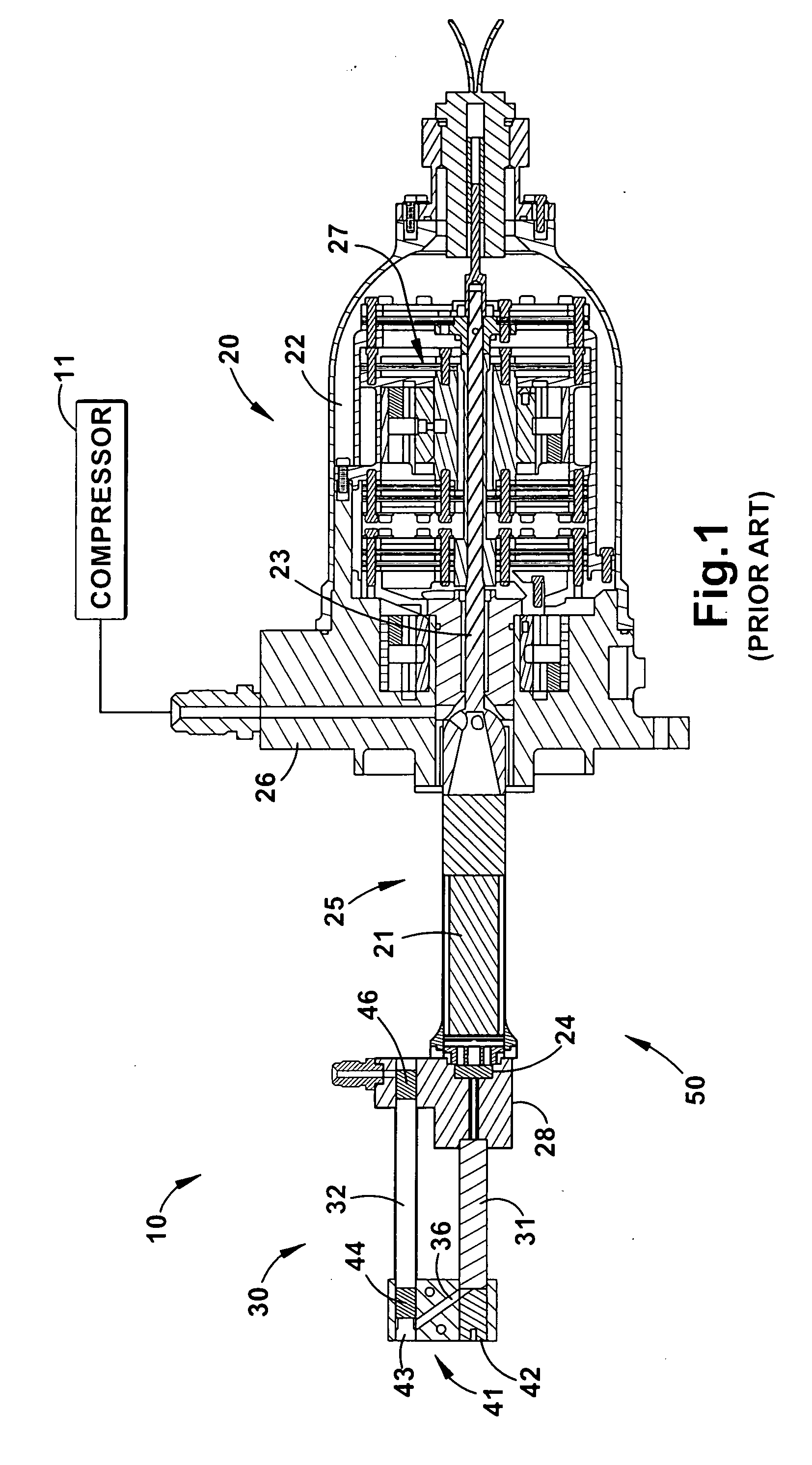

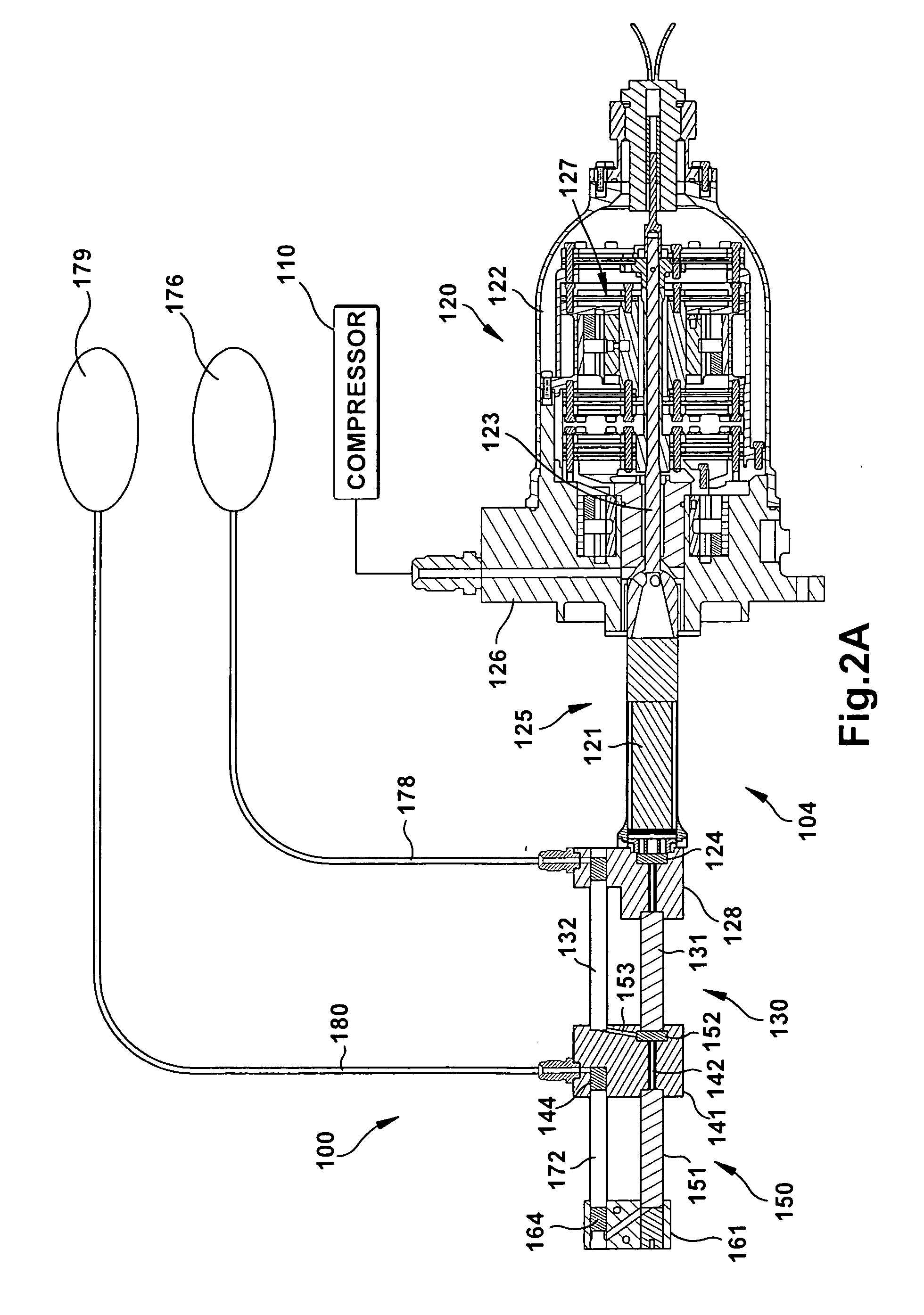

[0023] With reference initially to FIG. 2A, details are now discussed of a multi-stage cryocooler 100. The cooler 100 includes an active first stage 104, with a compressor 110 coupled to a first-stage expander 120, such as a Stirling expander. The expander 120 may be substantially identical to the expander 20 of the prior art cryocooler 10 (FIG. 1), and may include such parts as a first-stage regenerator 121, a plenum 122, and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com