Wire crimping tool

a crimping tool and wire technology, applied in the field of crimping tools, can solve the problems of restricting the ability of accessing and crimping connectors, inconvenient use only one function of conventional crimping tools, so as to achieve convenient and versatile use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

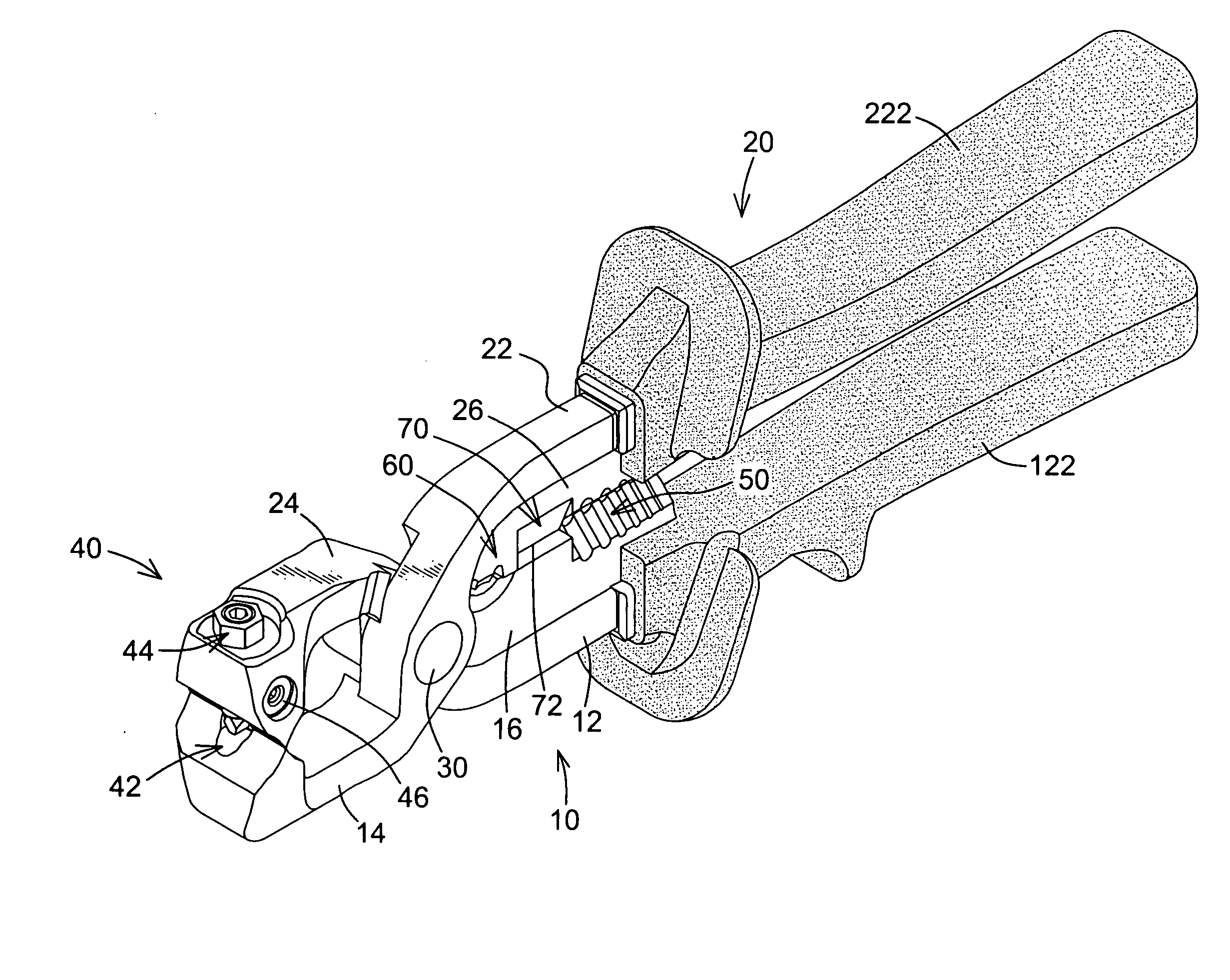

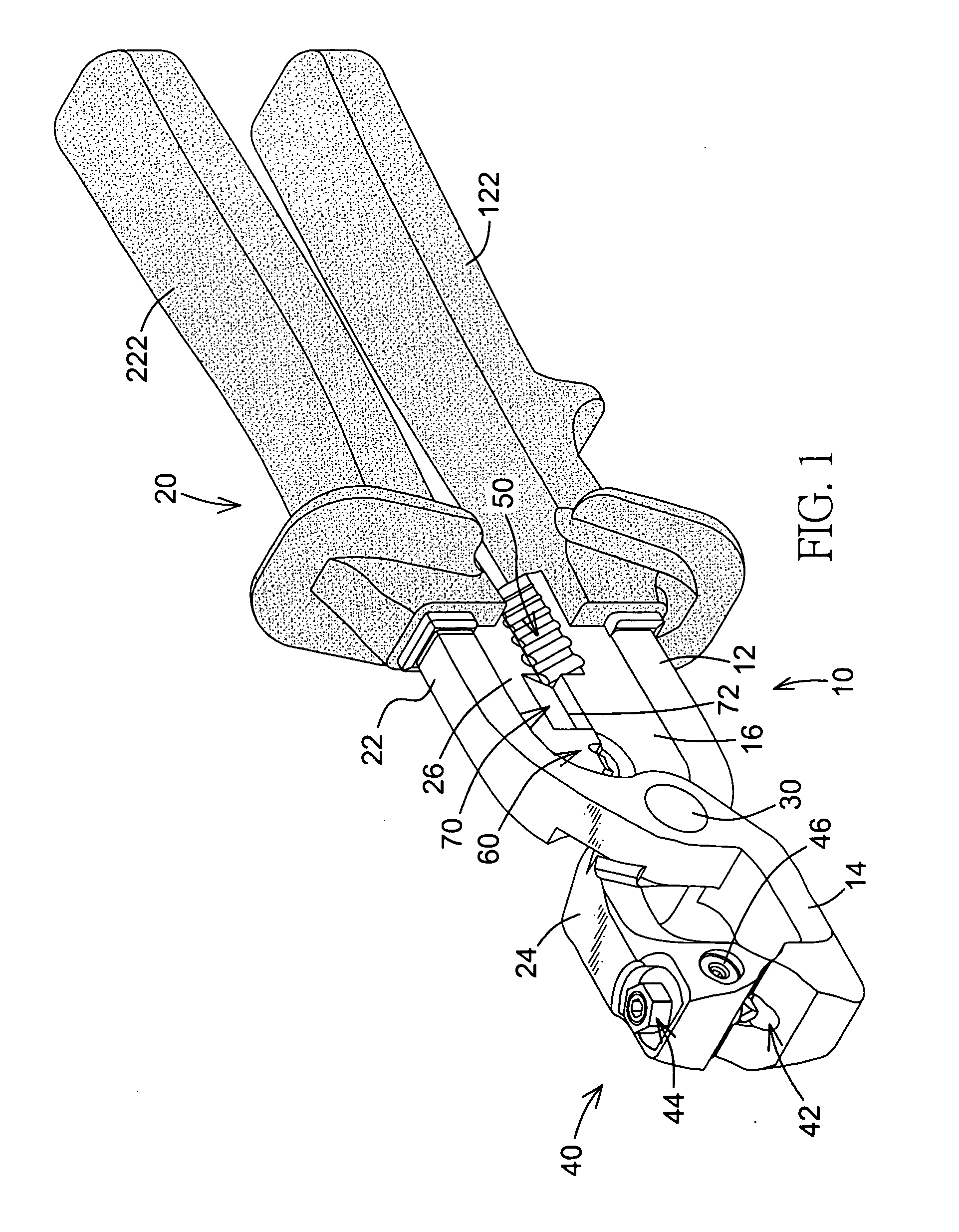

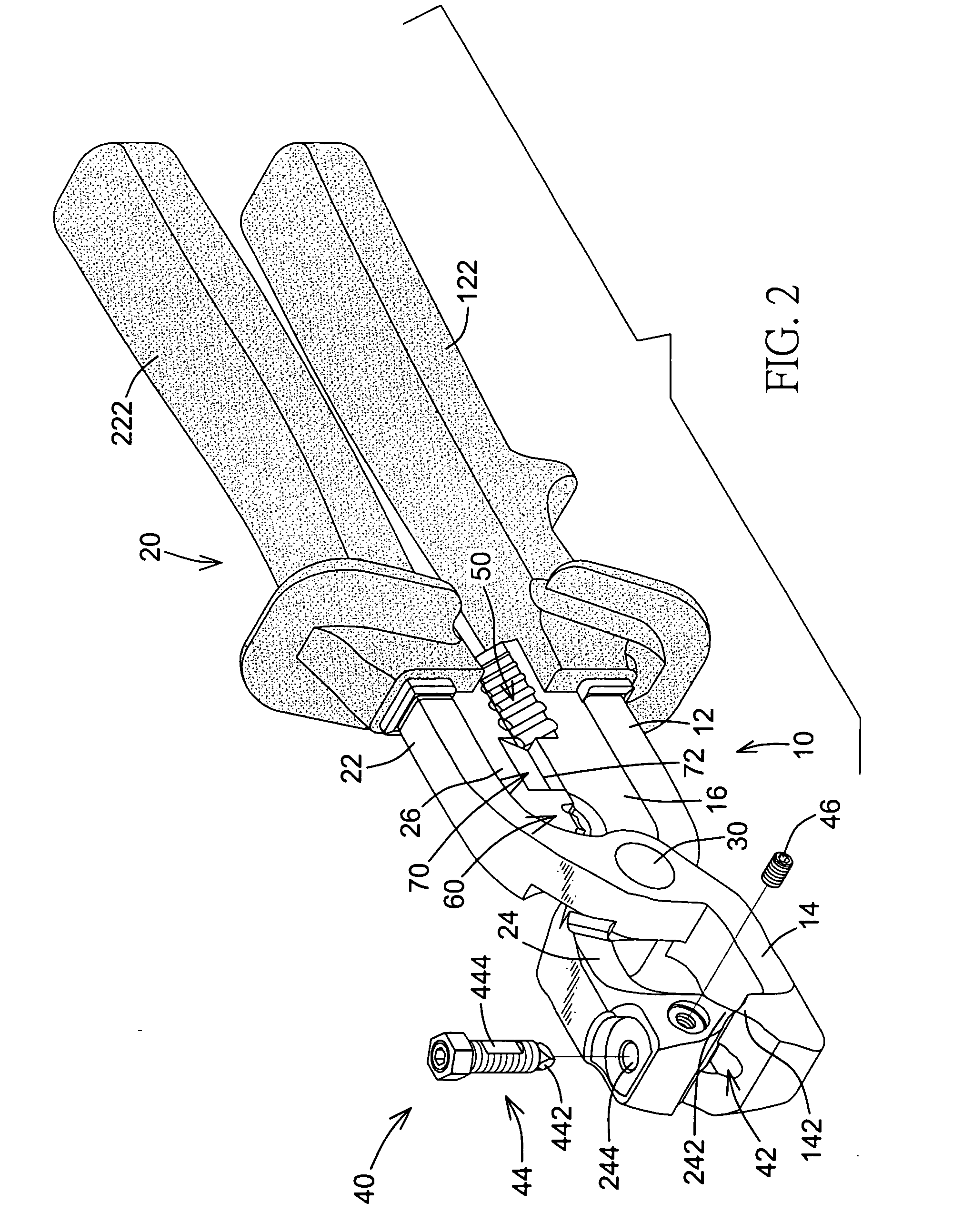

[0021]With reference to FIGS. 1 and 2, a wire crimping tool in accordance with the present invention comprises two arms (10,20) and an adjustable wire crimping device (40). The arms (10,20) are pivotally connected to each other with a pivot (30). Each arm (10,20) having two ends, a handle (12,22) formed one end of the arm (10,20) and a jaw (14,24) formed on the other end of the arm (10,20). Each arm (10,20) has a coat (122,222) made of an insulating material mounted around the handle (12,22) of the arm (10,20).

[0022]Each jaw (14,24) is C-shaped to define a space between the jaws (14,24). With further reference to FIGS. 3 and 4, the jaws (14,24) each have a cutting end (142,242) facing and selectively abutting against with each other, and the cutting end (142,242) of each jaw (14,24) has a triangular section to form a sharp tip (143,243) on the cutting end (142,242). The sharp tips (143,243) can be used to cut a wire and strip the insulation off wires.

[0023]With further reference to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| insulating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com