Drawer slide assembly

a slide assembly and drawer technology, applied in the field of drawer slide assembly, can solve the problems of not including other protective or locating mechanisms, increasing frictional resistance, preventing the drawer box from being smoothly and stably opened or closed, etc., to achieve smooth and stable opening and closing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

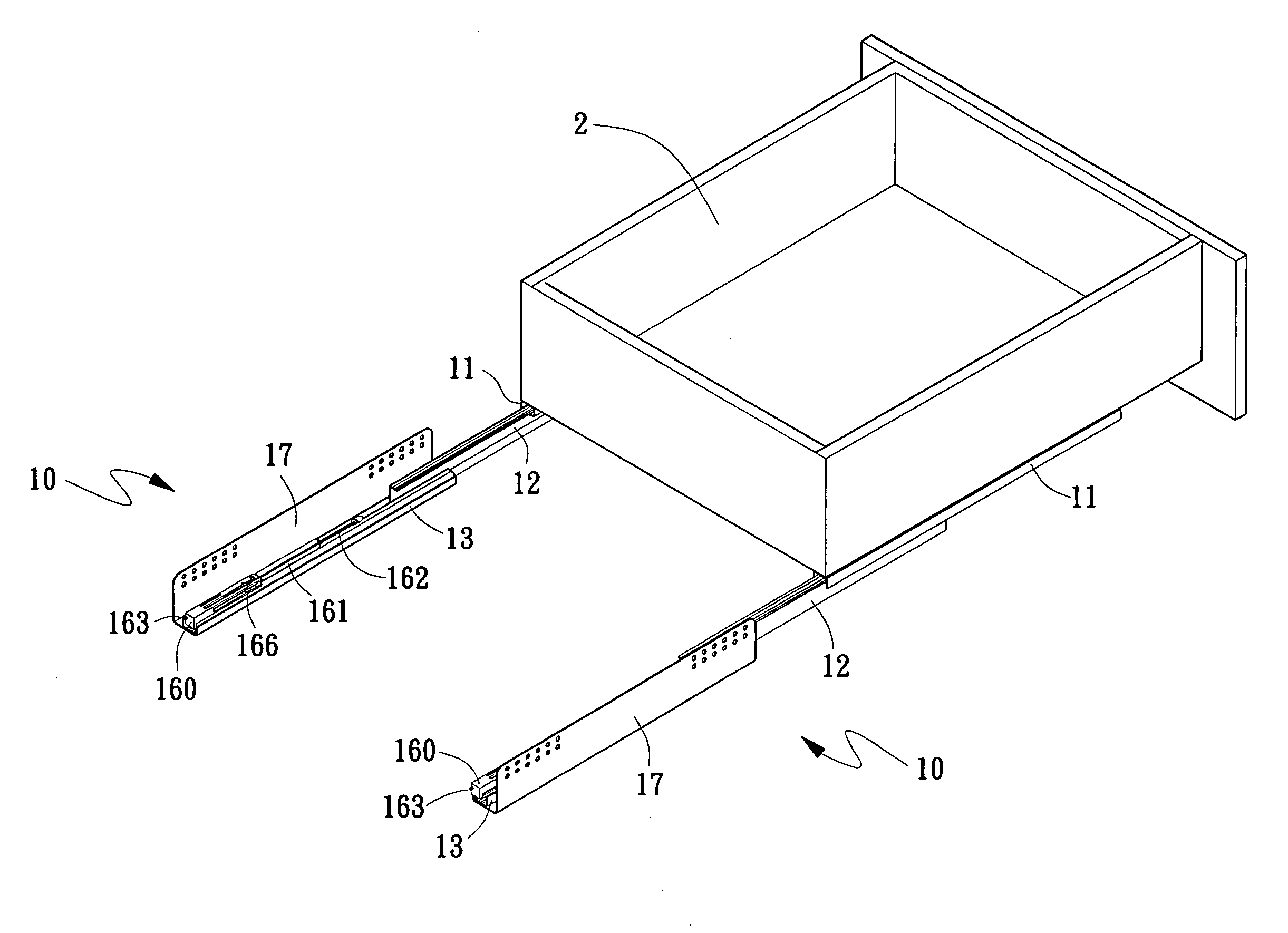

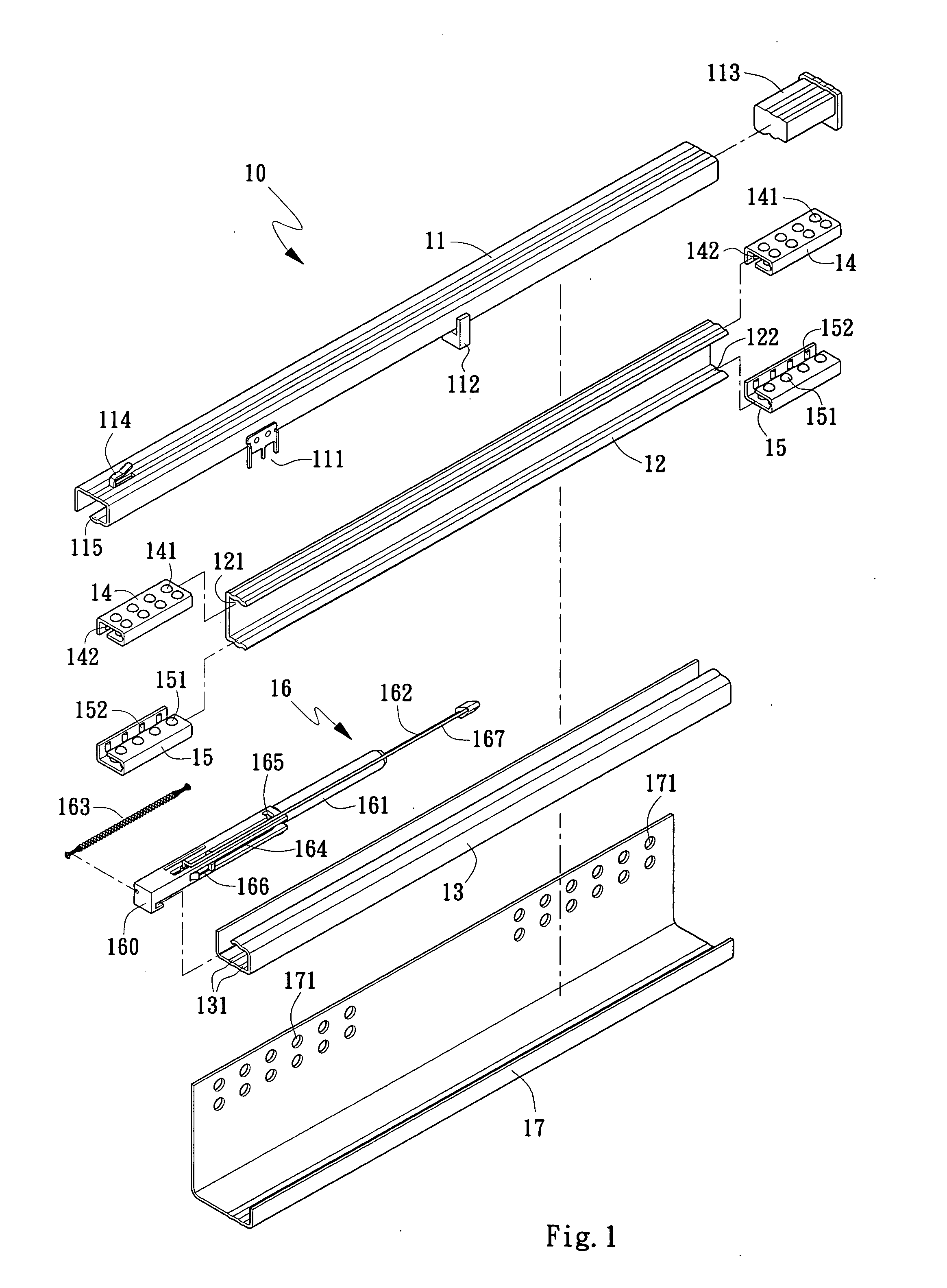

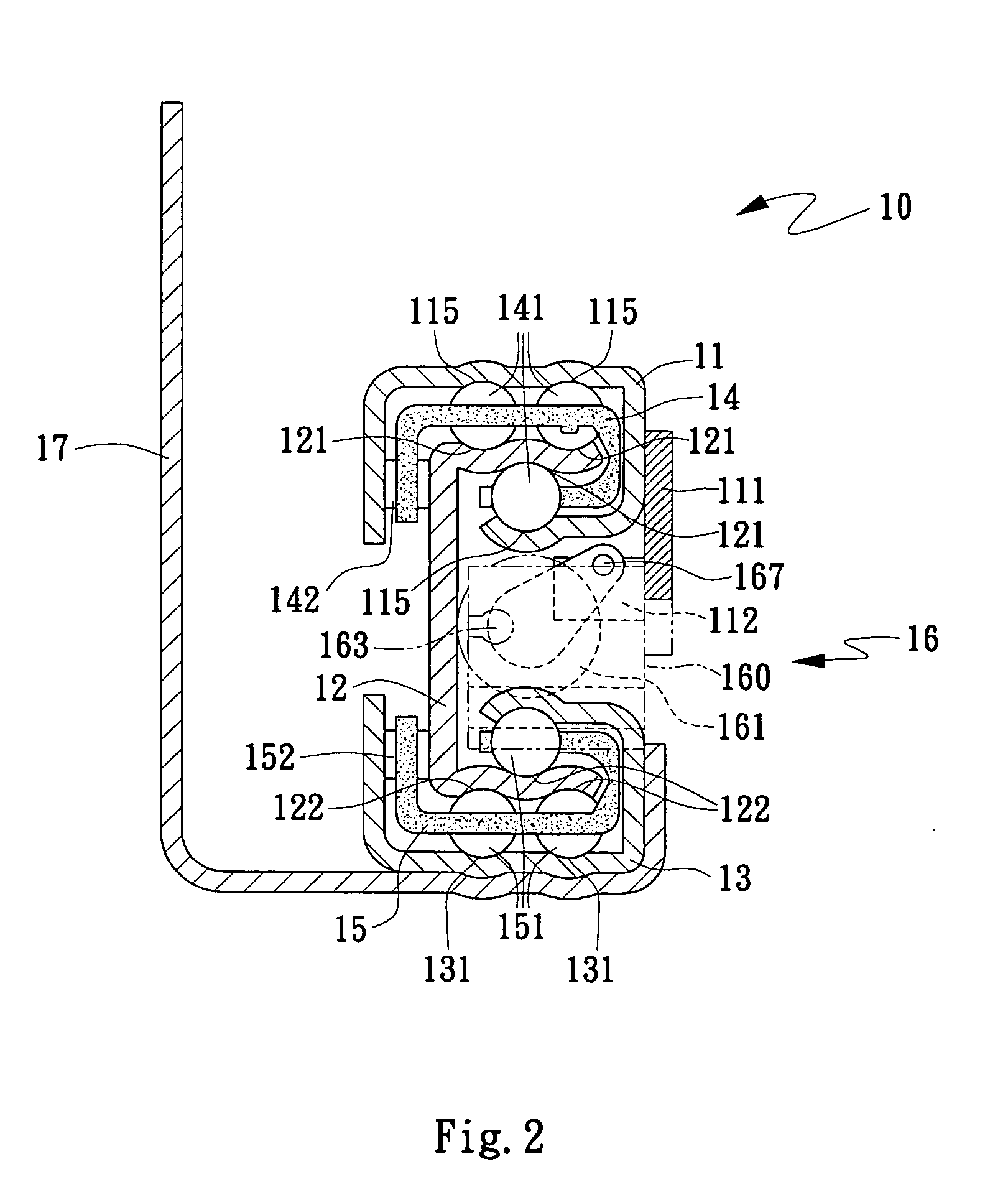

[0016]Please refer to FIG. 1 that is an exploded perspective view of a drawer slide assembly 10 according to an embodiment of the present invention, and to FIG. 2 that is an assembled sectional view of FIG. 1. As shown, the drawer slide assembly 10 of the present invention includes an upper slide 11; an inner slide 12 having a buffer unit 16 located therein; at least two upper sliding guides 14; and a mounting plate 17 provided with a plurality of mounting holes 171 for holding the assembled upper slide 11 and inner slide 12 to a fixed place.

[0017]The upper slide 11 has an outer end closed with a stopper 113, so as to prevent external dust from invading the upper slide 11 to adversely affect the smooth moving of the upper sliding guides 14 in the upper slide 11.

[0018]Each of the upper sliding guides 14 is provided on a top and a bottom with a plurality of first sliding bearings 141, such that the first sliding bearings 141 located at the top of the upper sliding guides 14 bear again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com