Ball injecting apparatus for wellbore operations

a wellbore and ball injection technology, applied in the direction of borehole/well accessories, fire extinguishers, fluid removal, etc., can solve the problems of failure of well treatment operations, valve malfunction, ball sticking to the bottom of the well, and high danger of treatment fluid,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Wellbore Operations

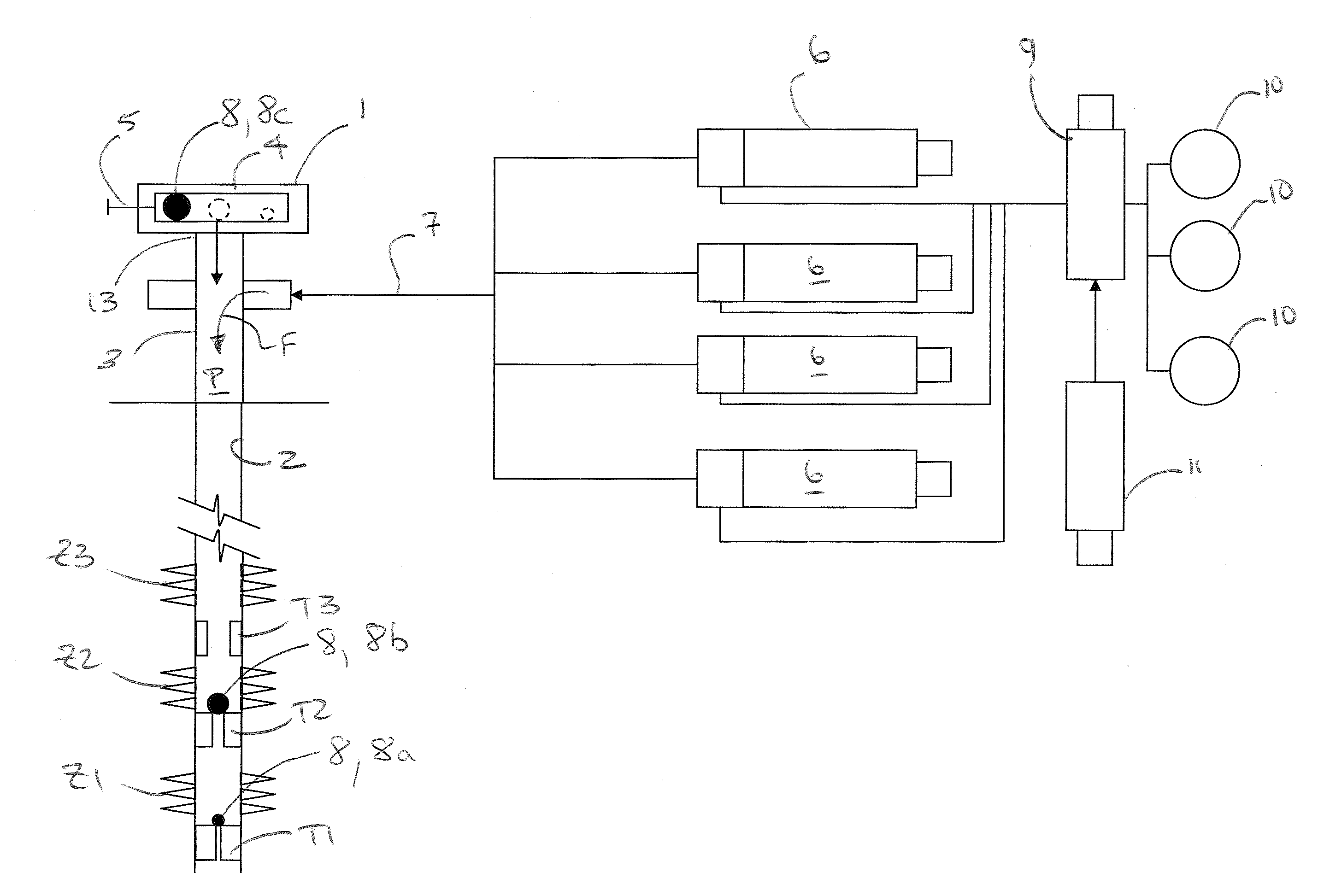

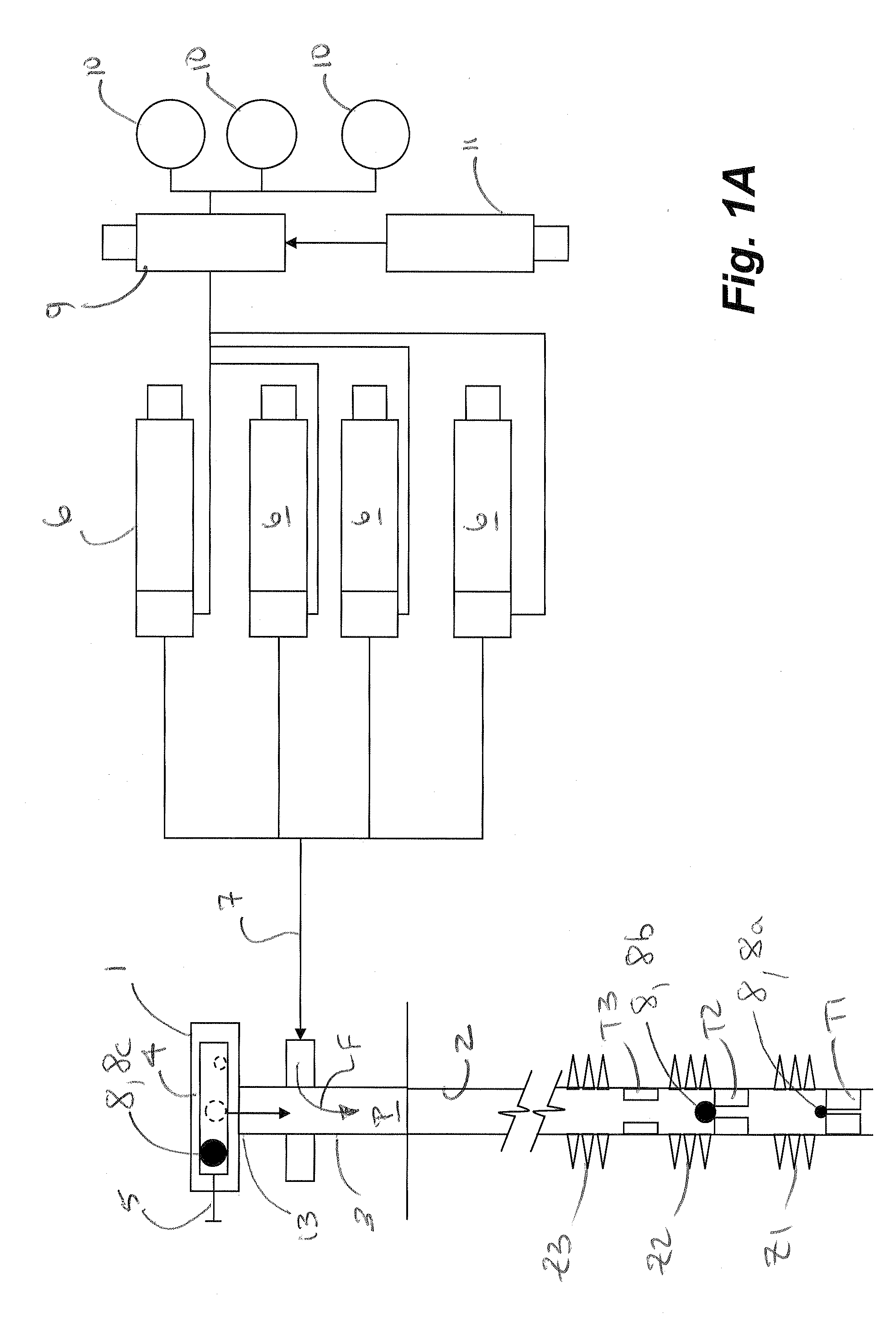

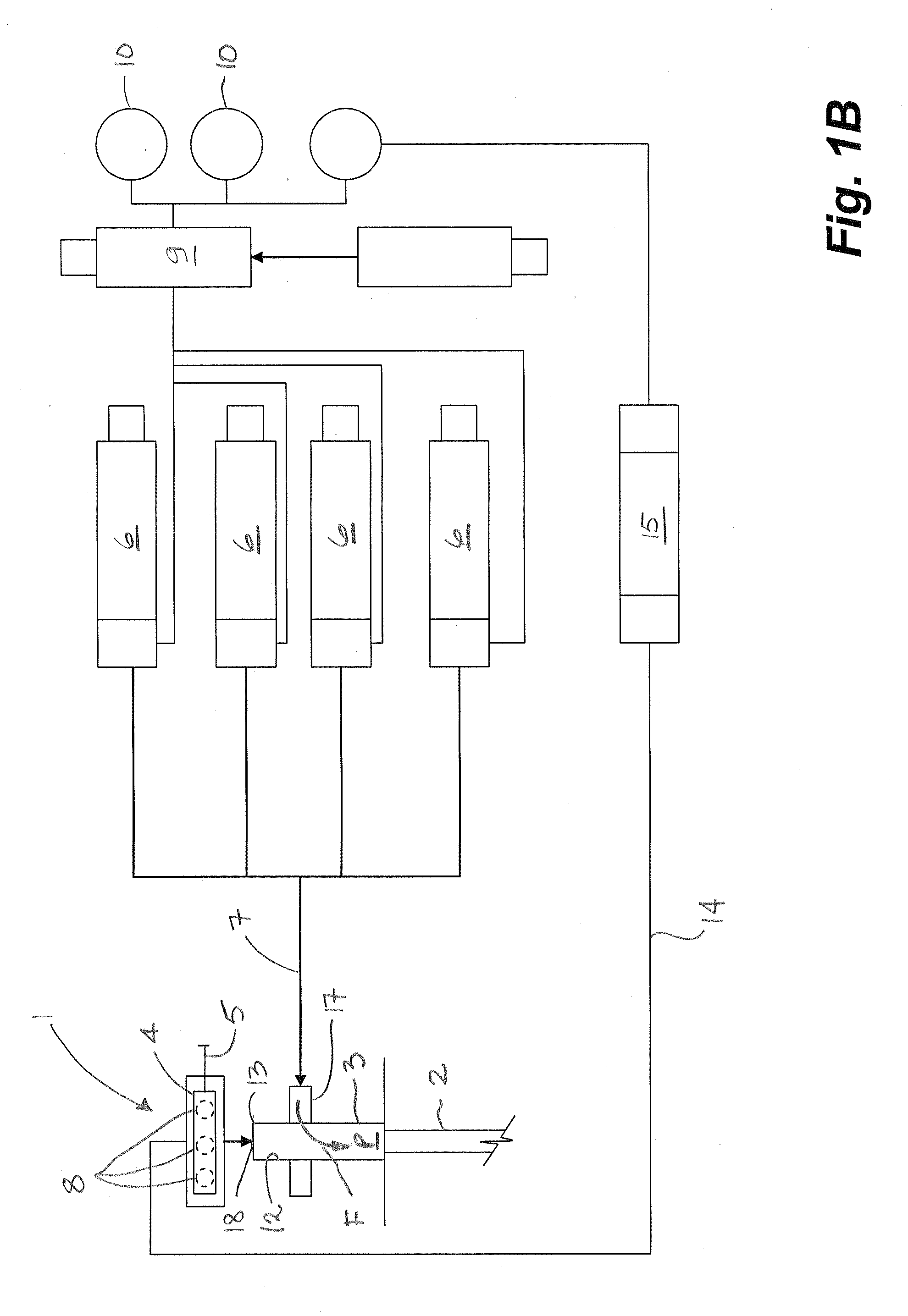

[0057]With reference to FIGS. 1A and 4A-4D, a system and method for conducting operations on a wellbore 2 are provided. The wellbore 2 is fit with two of more downhole tools T1,T2,T3, such as packers spaced at intervals along the wellbore for isolation of a first zone and subsequent zones Z1,Z2,Z3. The system and methodology can implement an embodiment of the ball injecting apparatus 1 of the present invention.

[0058]With assistance of the embodiment illustrated in FIG. 1A, the ball injecting apparatus 1 is mounted with the transverse port 37 fluidly connected directly atop a stimulation multi-port wellhead 3. A flow F of stimulation fluids 7 can be provided to the wellhead 3 and the apparatus 1 can inject drop balls 8 into the flow path P for delivery down the wellbore 2. As is known by those of skill in the art, operations on the wellbore can include actuating a first packer T1 for blocking flow therebelow so that stimulation operations can be conducted on a zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com