Package Advancement System

a packaging and positioning technology, applied in the field of packaging advancement systems, can solve the problems of not being able to easily roll or slide along the shelf, not being able to dispense packages in certain orientations on the shelf, and gravity no longer being the only source of packaging dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

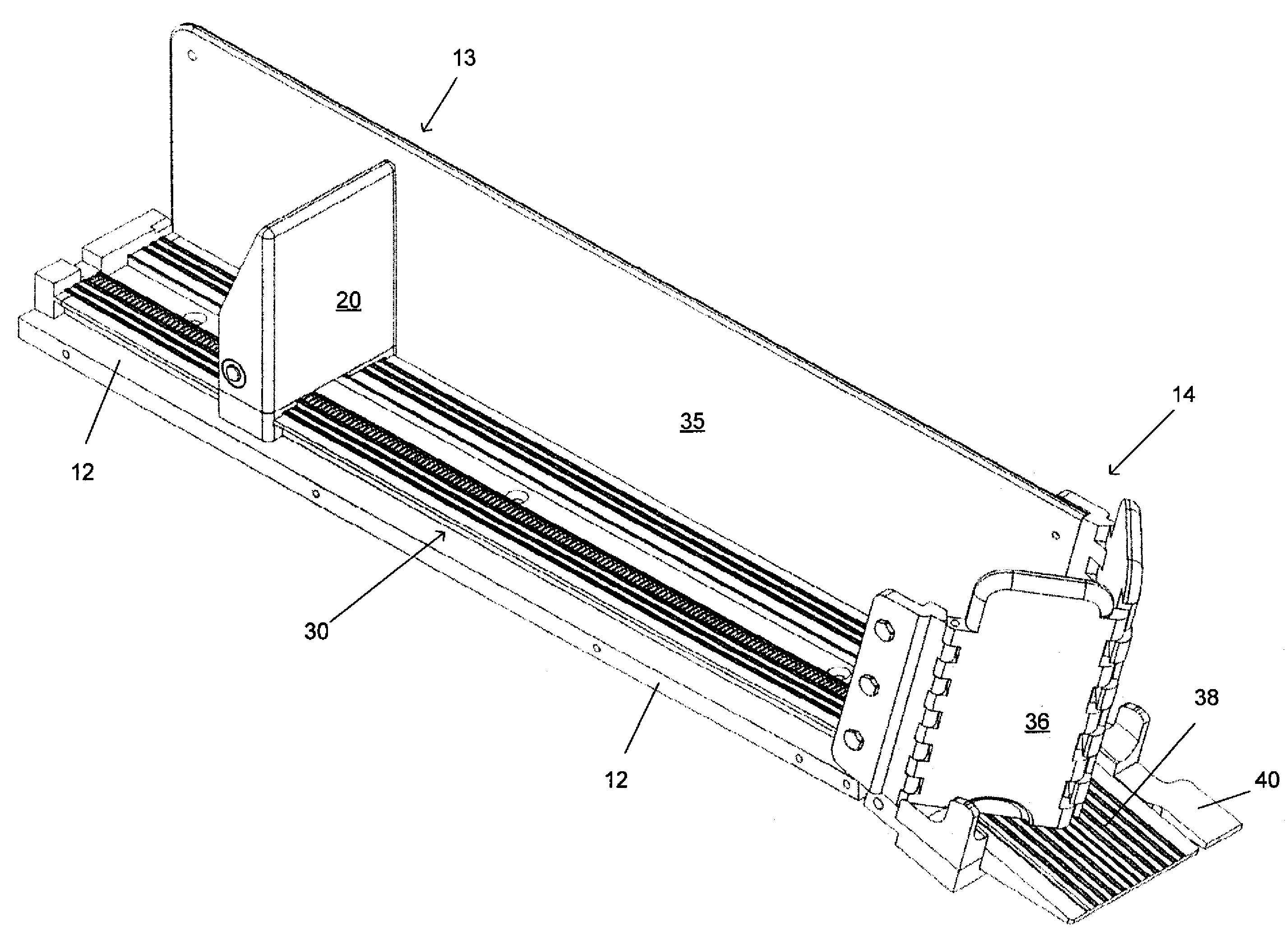

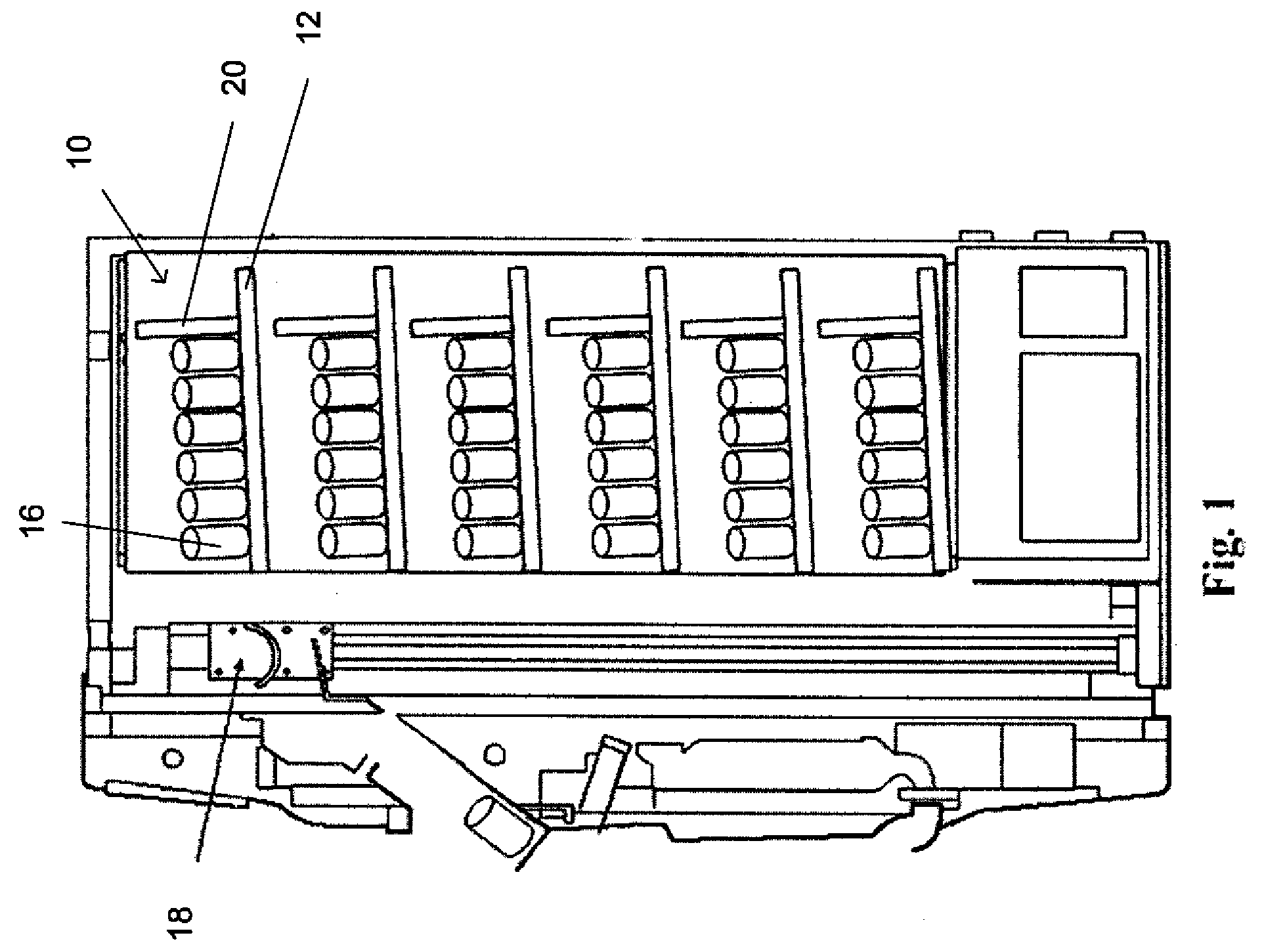

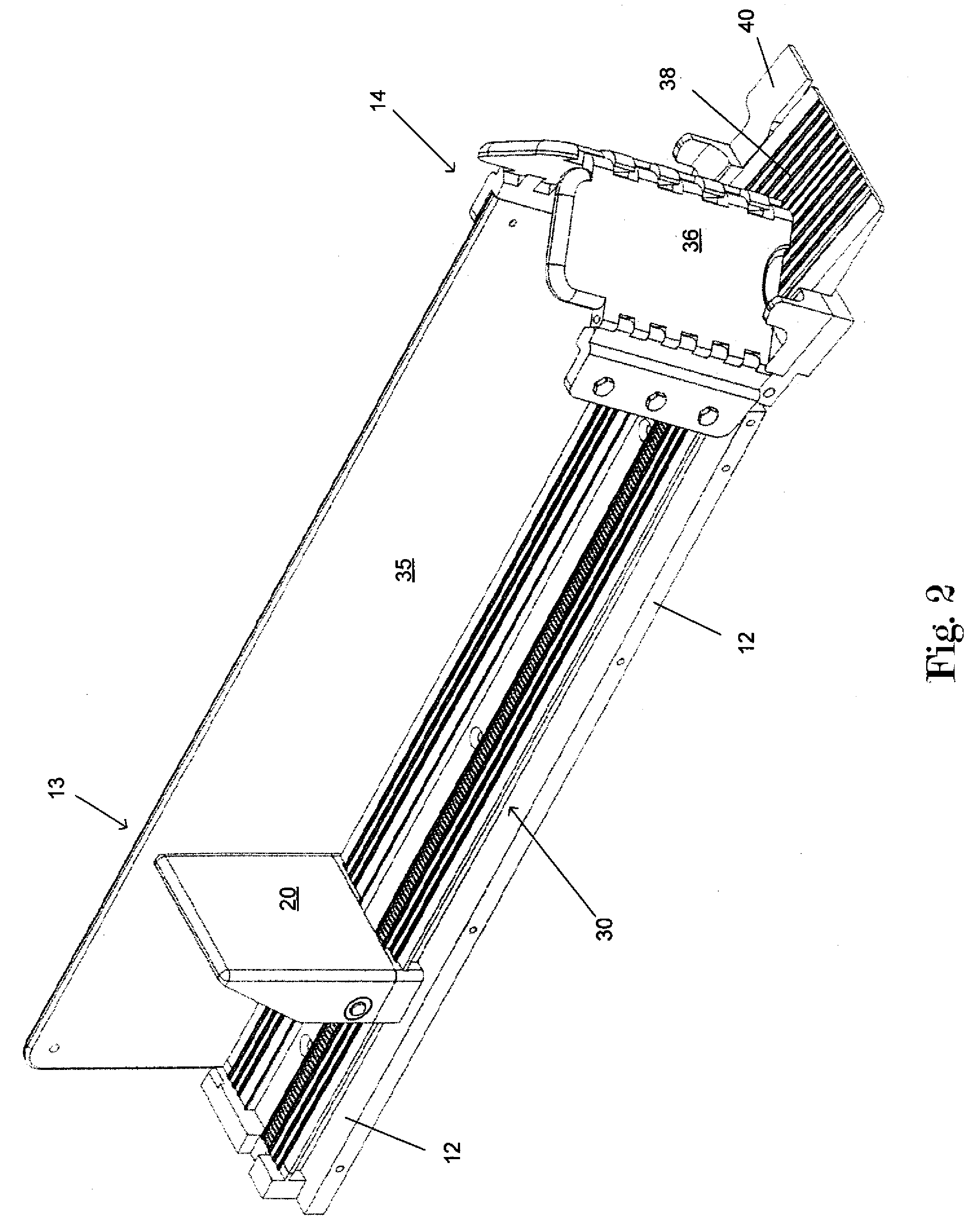

[0013]Generally described, the present application relates to a package advance system to move a package along a shelf of a dispensing unit and to assist in the loading of the packages onto the shelf. The package advance system may include an end plate positioned on the top of the shelf. The end plate may be affixed to a spring system. The spring system may attempt to push or pull the end plate towards a dispensing end of the shelf. The spring system may include a spring to move the end plate. The spring system may further include a damper to modify the rate and force that the spring exerts on the end plate.

[0014]The end plate may interface packages disposed on the shelf. The spring system forces the end plate to interface with the packages. If a space or gap exists amongst the packages on the shelf, the spring system may move the end plate to push the packages together collectively towards the dispensing end of the shelf. For example, if the product at the dispensing end of the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com