Partially reusable surgical stapler

a stapler and part-reusable technology, applied in the field of surgical staplers, can solve the problems of difficult sterilization after use, relatively complicated mechanical instruments with reusable staplers, etc., and achieve the effect of convenient replacement, convenient replacement and convenient replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

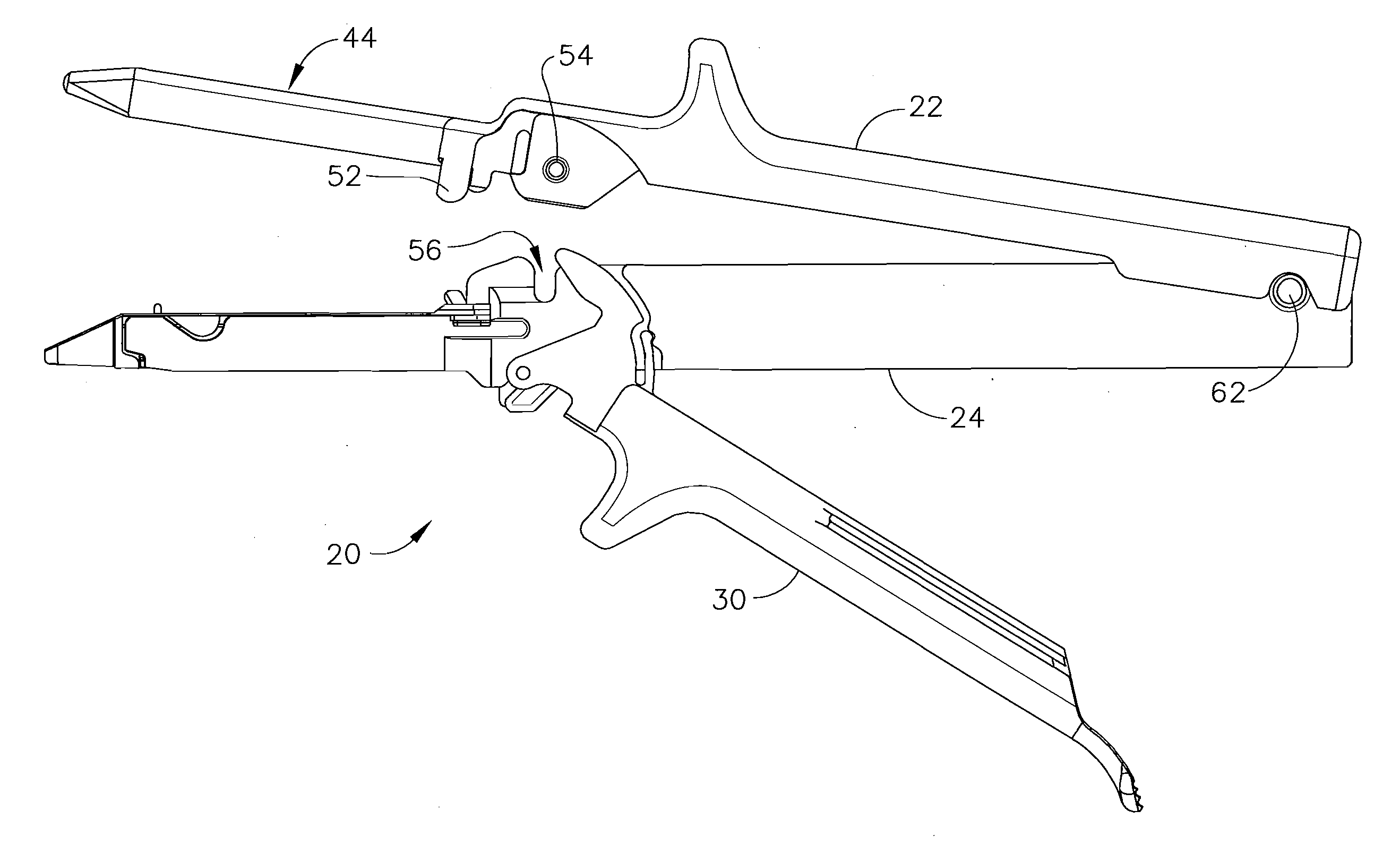

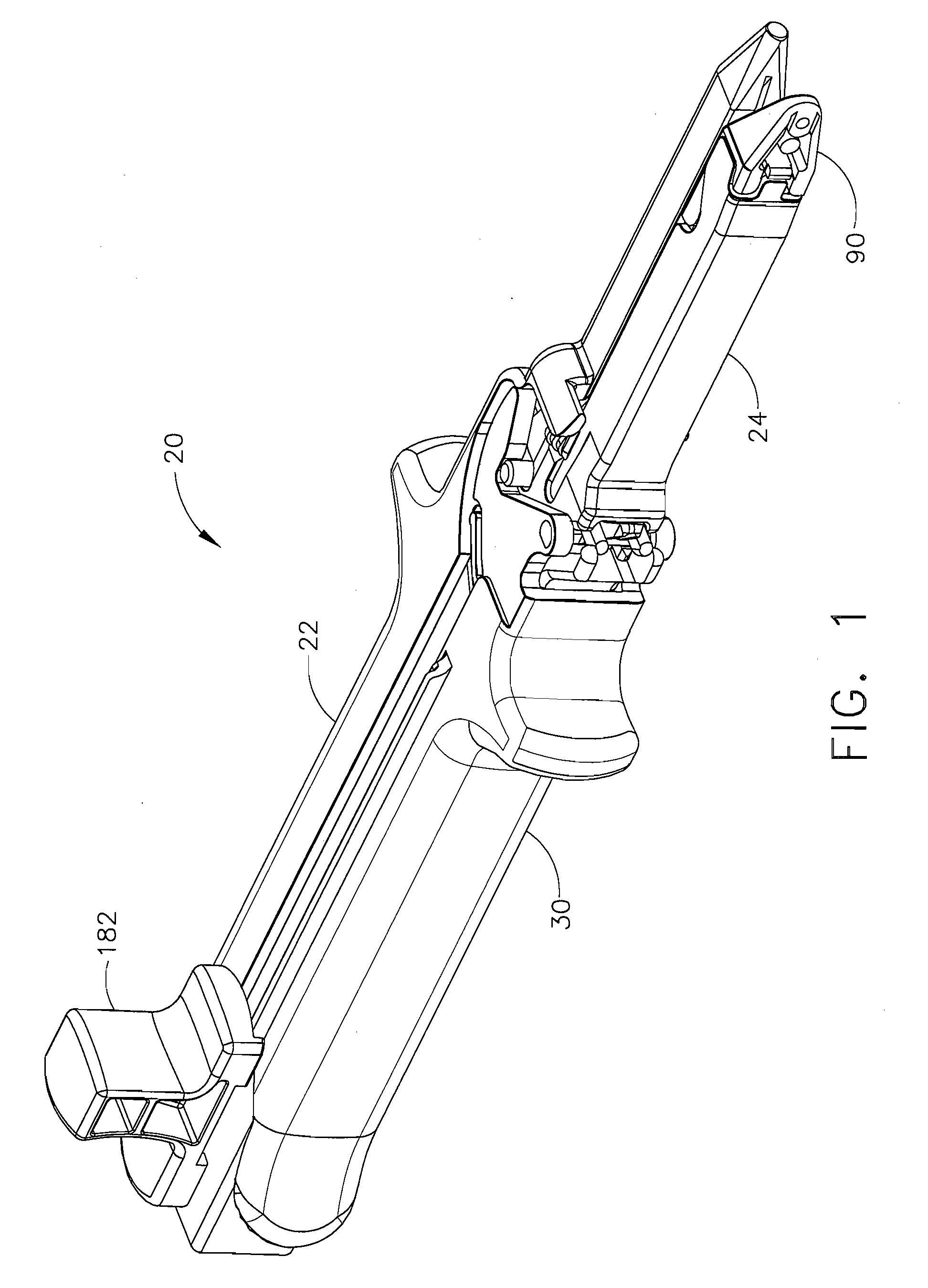

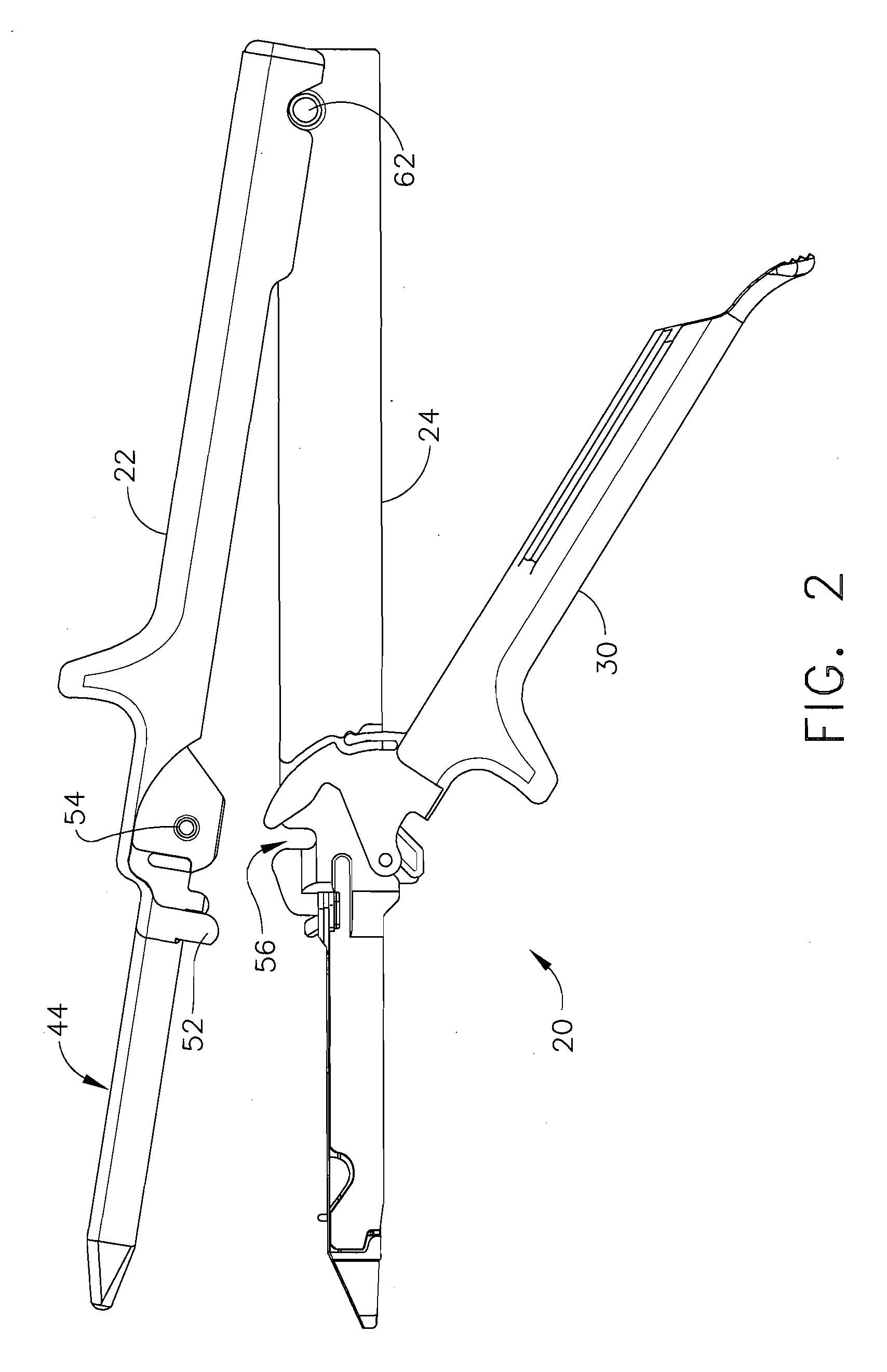

[0036]Referring now to the drawing figures, in which like numerals indicate like elements throughout the views, FIGS. 1 through 3 illustrate a first exemplary surgical stapler 20 of the present invention. The body of stapler 20 includes an upper jaw member 22, a lower jaw member 24, and a latching member 30. Latching member 30 is pivotable relative to the upper and lower jaws members 22, 24, as shown in FIGS. 2-3. Latching member 30 can be pivoted through a series of different latching states to lock the stapler closed for use or to open the stapler varying degrees to allow for adjustment of tissue within the stapler, the replacement of a staple cartridge, or disassembly of the stapler. Upon completion of a surgical procedure, latching member 30 can be pivoted to a fully open position to allow stapler 20 to be disassembled in preparation for the resterilization and reuse of portions of the stapler.

[0037]As shown in FIGS. 4 and 5, upper jaw 22 comprises a single piece, elongated chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time intensive | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com