Adjustable Rear Iron Sight for a Fire Arm

a rear iron sight and fire arm technology, applied in the direction of sighting devices, weapon components, weapons, etc., can solve the problems of inconvenient use, loss of initial zero range setting, and increments of elevation too large to achieve the effect of preventing looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

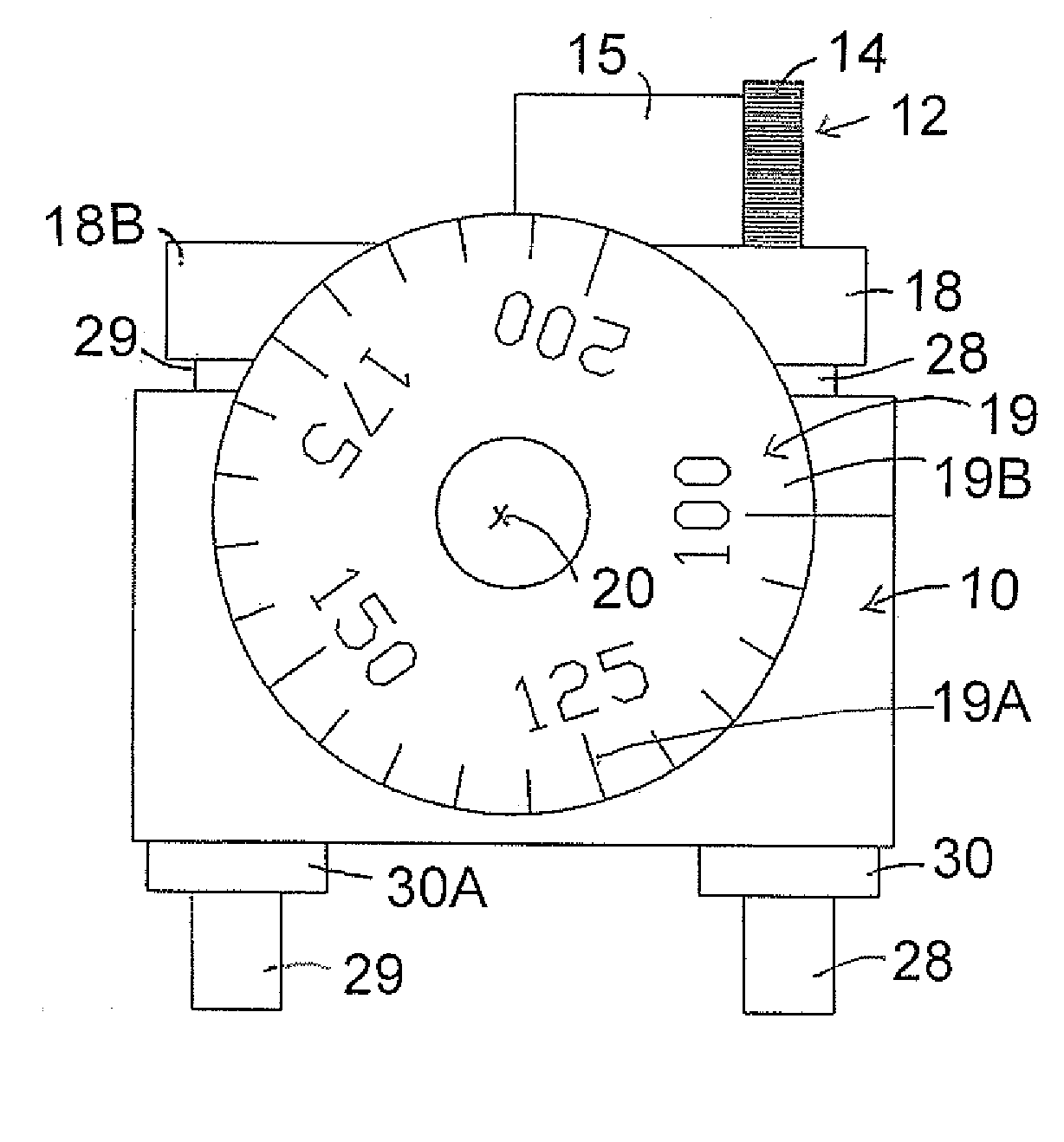

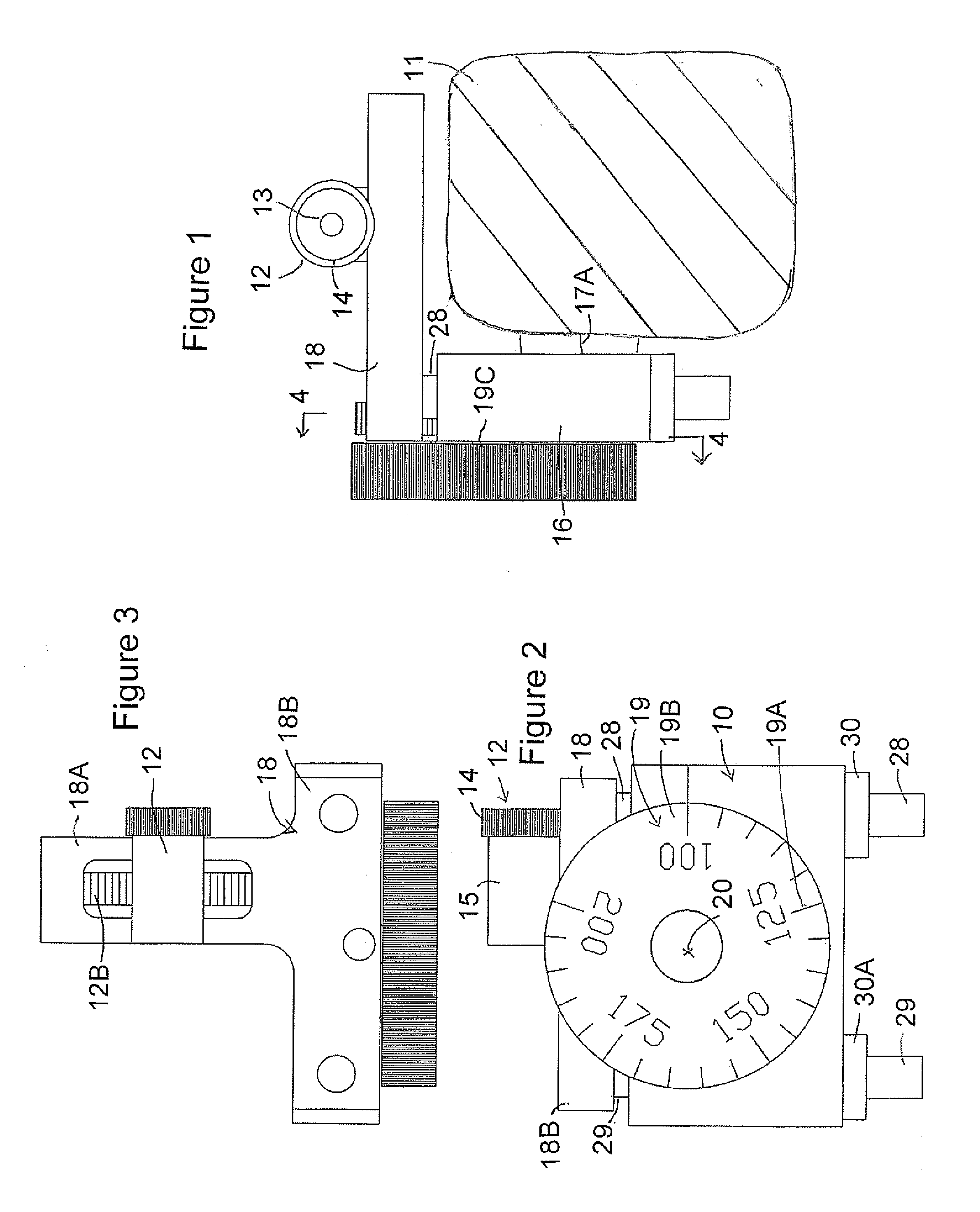

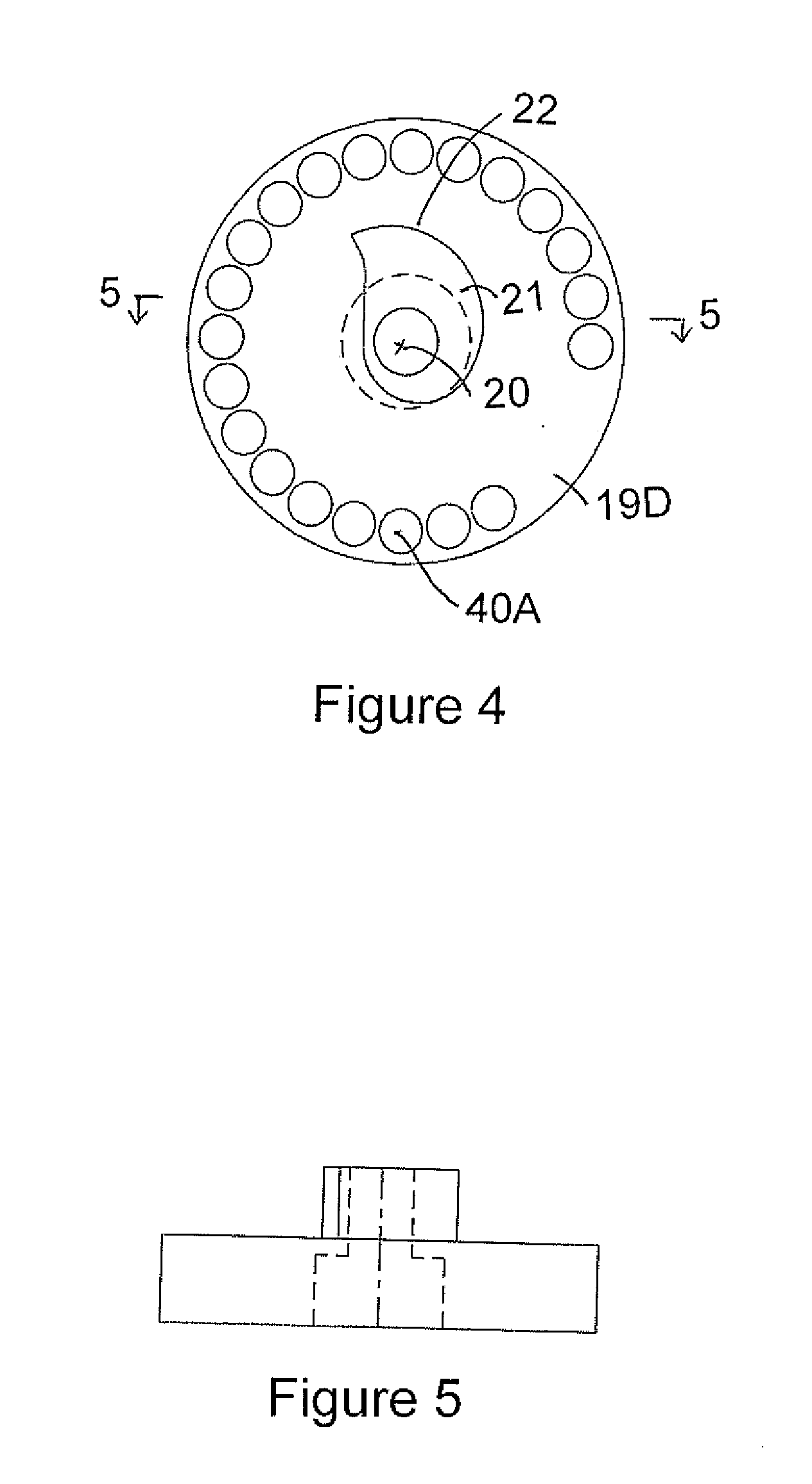

[0072]An adjustable rear iron sight 10 is provided for a firearm 11 for cooperation with a fixed front sight (not shown) where the user aligns the front and rear sights to aim the fire arm in a required direction.

[0073]The sight comprises a rear sighting element 12 which is shown in the form of an aperture 13 carried in a screw-in insert portion 14 for mounting in a housing 15. This is mounted generally at a rear of the fire arm and defines a visible alignment portion defined by the aperture for visual alignment by the user with the front sighting element (not shown). Other types of sighting elements can be used which allow the user to locate the rear sight relative to the front sight as are well known in the industry.

[0074]In general, the element 12 is carried on an a mounting member in the form of a mounting block 16 having mounting elements 17 for attachment of the mounting member 16 to the firearm 11. An adjustable member 18 is carried on the mounting member 16 and is adjustably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com