Separation of a Fluid Mixture Using Self-Cooling of the Mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

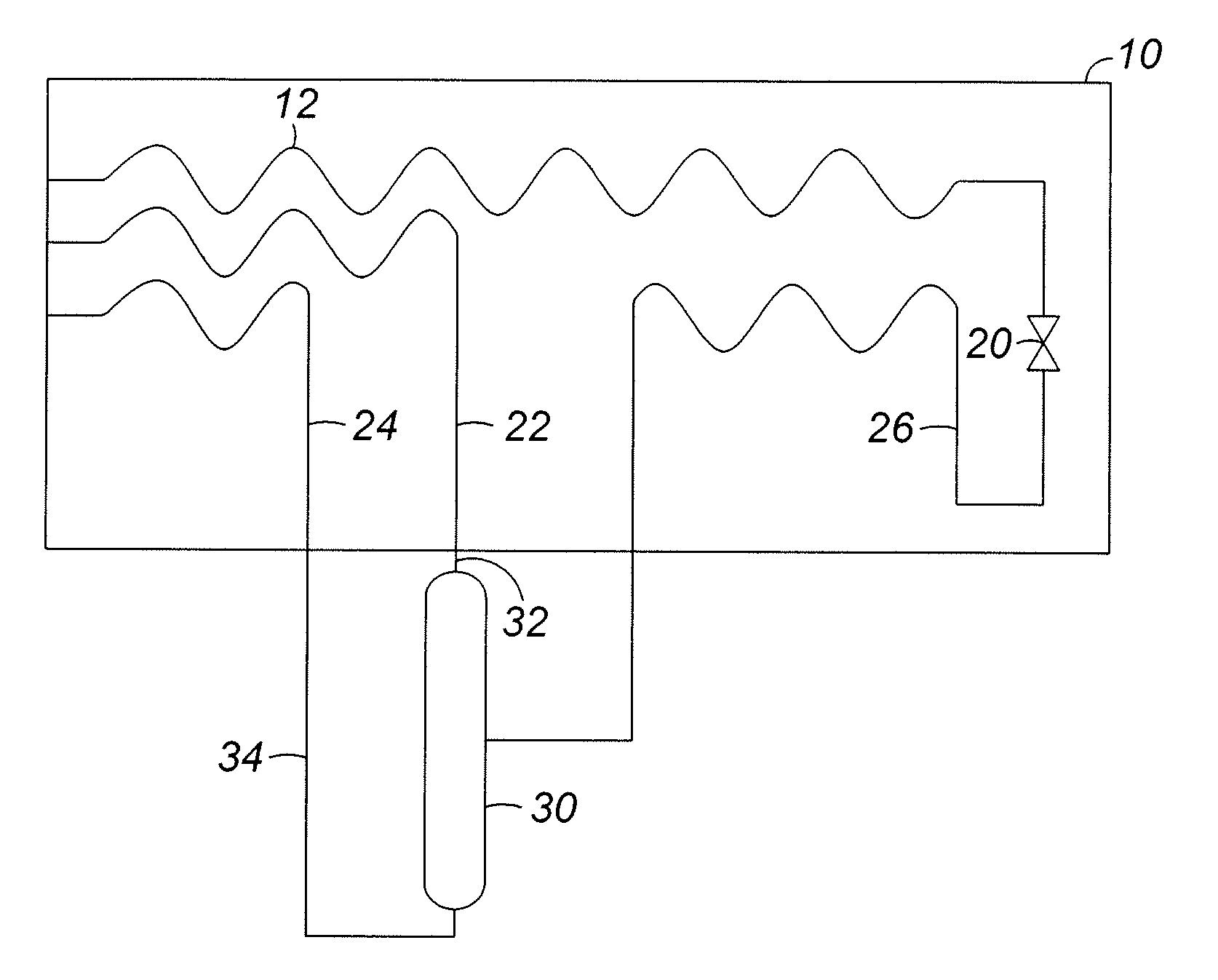

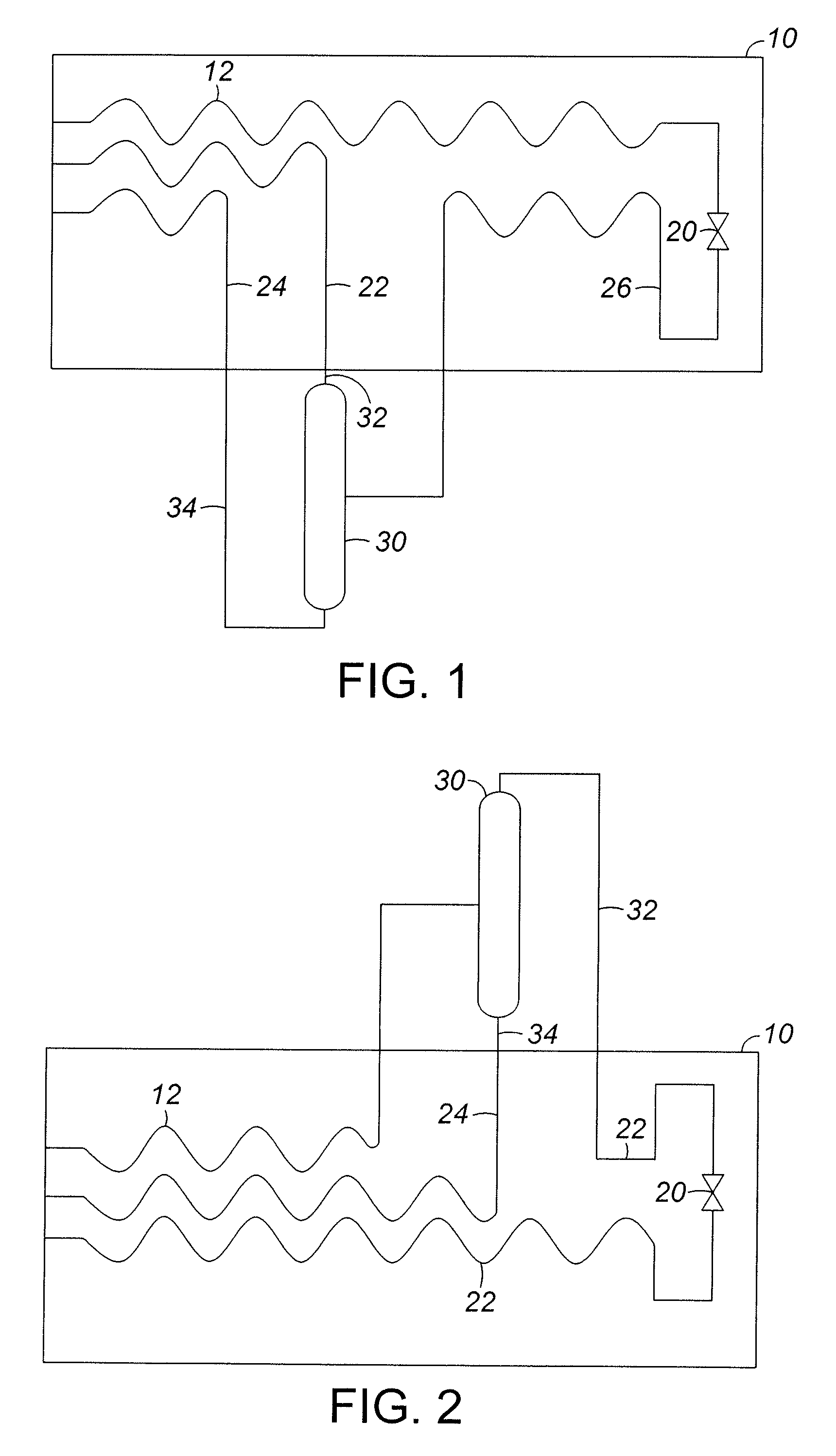

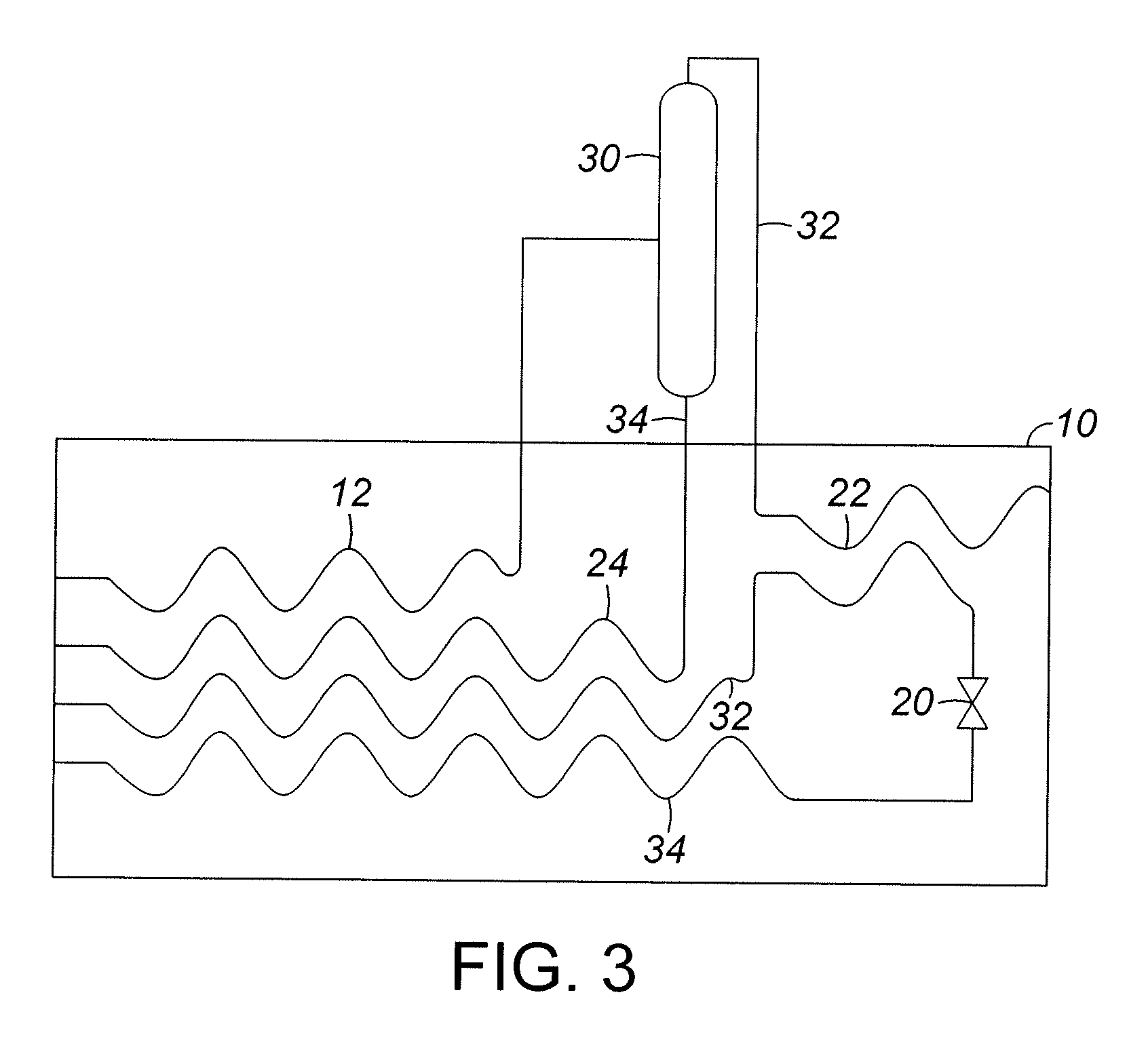

[0010]The use of liquefied natural gas (LNG) is increasing, as fuel and a means of transporting natural gas from remote sites having natural gas, without a nearby gas pipeline, to more distant areas where the natural gas is consumed. Natural gas is typically recovered from gas wells that have been drilled and is in the gas phase at high pressure. The high pressure gas is then treated and passed to a pipeline for transport. However, there are an increasing number of natural gas fields that are in remote locations relative to natural gas pipelines. The present invention is directed to a heat exchanger for cooling the natural gas at the gas wells. By providing an inexpensive heat exchanger for cooling and liquefying natural gas in remote locations, natural gas can be recovered on site and transported as LNG, rather than requiring a natural gas pipeline, or transporting the gas at very high pressures. In addition, improved methods for liquefying natural gas can also lead to improved met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com