Offset leg framing element for fire stop applications

a technology of offset leg and frame element, which is applied in the direction of girders, fireproofing, walls, etc., can solve the problems of inefficient use of z-clips in this manner, high labor intensity, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

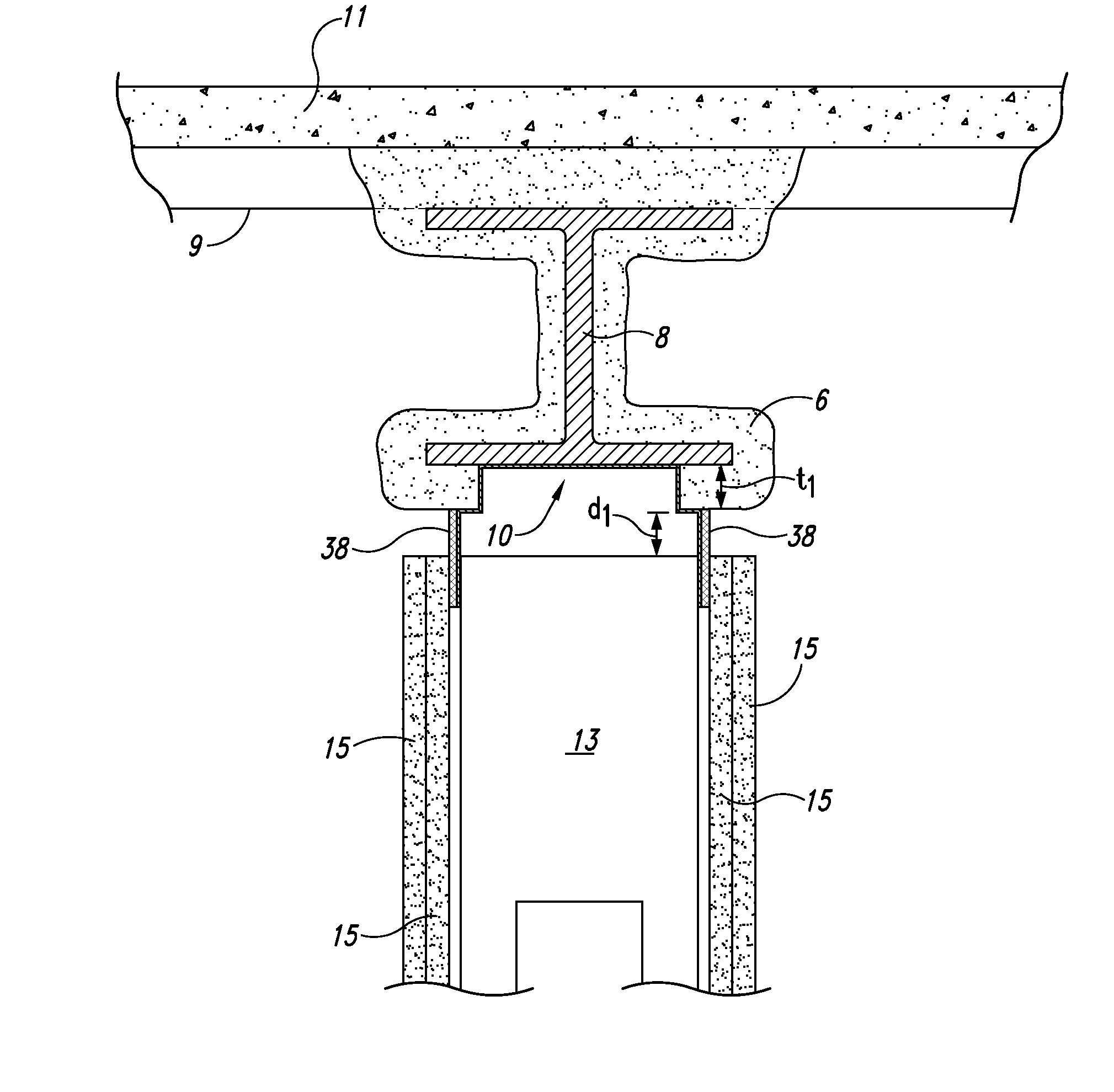

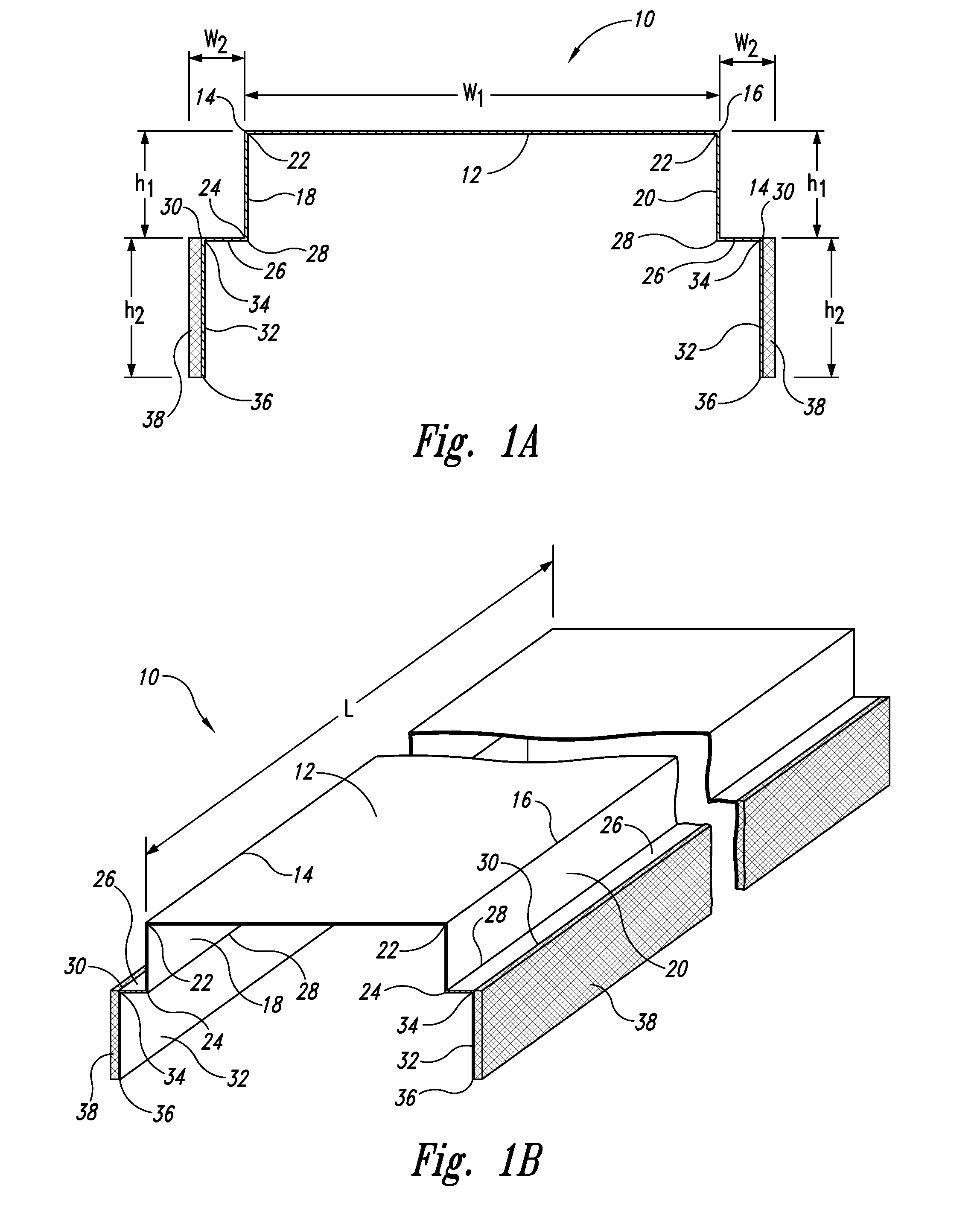

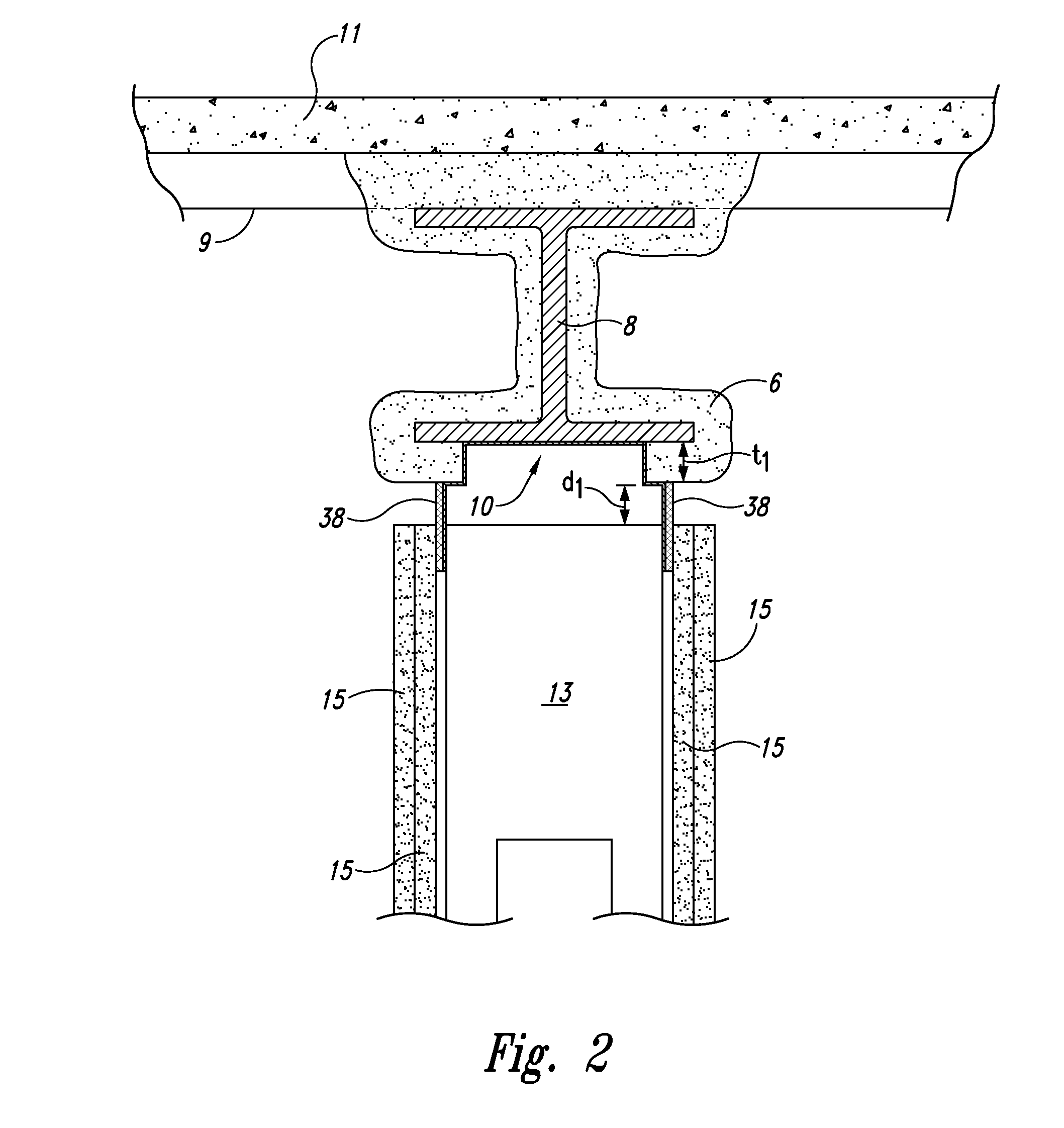

[0021]Referring now to the drawings wherein like reference numerals are used to designate like parts and features, the present invention in a first embodiment (and as best shown in FIGS. 1A-B) is directed to an offset leg framing element for use in a fire rated assembly (of a building). The offset leg framing element 10 comprises a web section 12 having opposing edges 14, 16, and a pair of outwardly extending sidewalls 18, 20 integrally connected to the web section 12. As shown, each sidewall 18, 20 has a proximal end 22 and a distal end 24, wherein the proximal end 22 of each sidewall 18, 20 is integrally connected to one of the opposing edges 14, 16 of the web section 12, and wherein the sidewalls 18, 20 are substantially parallel and confront each other.

[0022]The offset leg framing element 10 also comprises at least one laterally extending ledge section 26 integrally connected to one of the pair of outwardly extending sidewalls 18, 20. As shown, the at least one ledge section 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com