Beverage can marketing device with removable center cover

a beverage can and center cover technology, applied in the direction of caps, liquid handling, transportation and packaging, etc., can solve the problems of contamination issues on the outer surface of beverage cans and beverage can tops such as cans, and the conventional beverage can and beverage can top configuration such as the can b> suffer from a variety of deficiencies, so as to increase sales, easy to wipe and remove, and steal market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

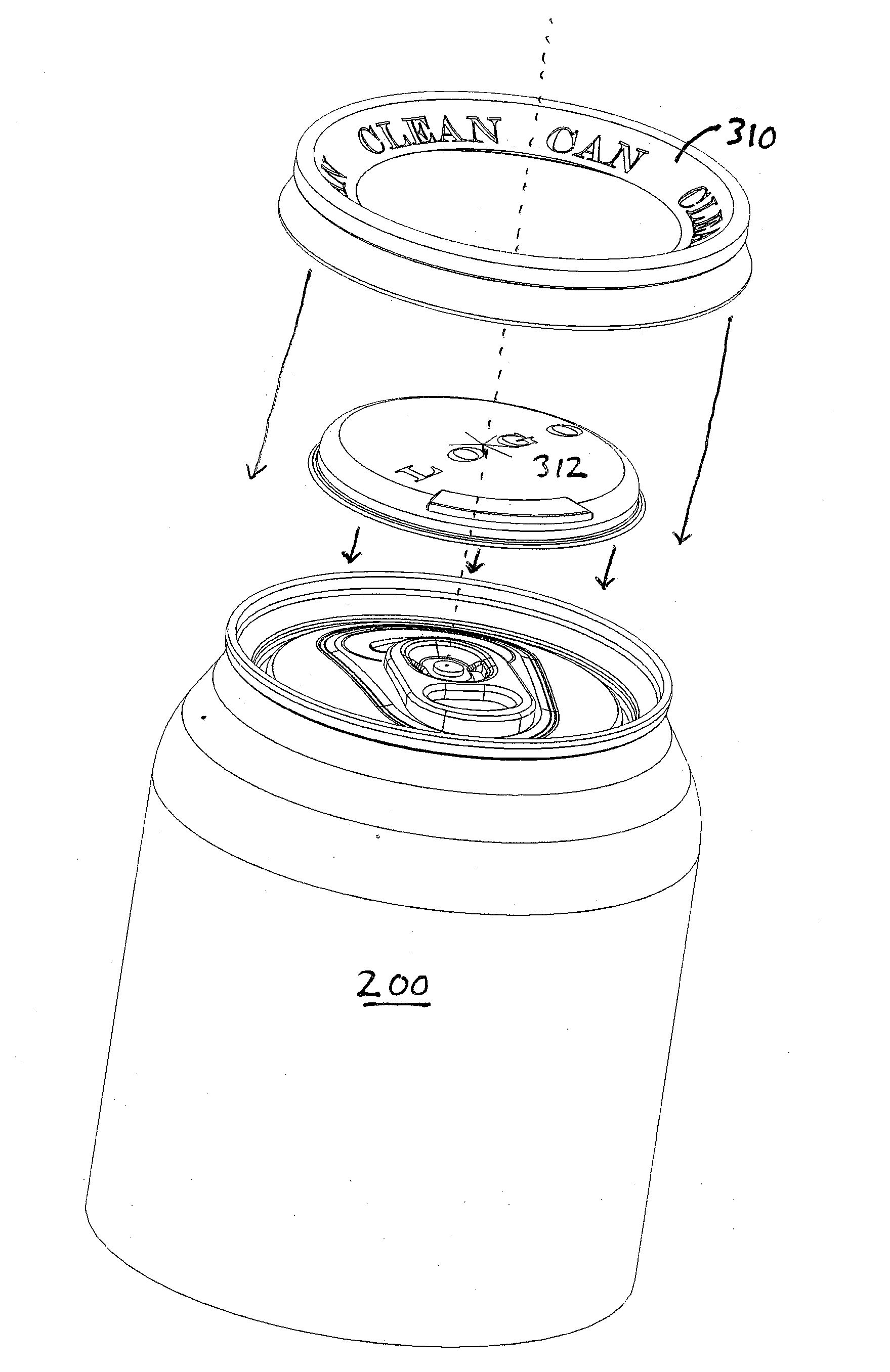

[0058]FIG. 3 shows a can top device 300 configured in accordance with one example embodiment of the present invention. FIG. 4 shows a beverage can 200 (e.g. a soda can, beer can or other beverage can) on which the can device 300 from FIG. 3 is installed.

[0059]The can top device 300 in FIGS. 3 and 4 includes a rim section 310 and a removable central cover 312. The rim section 310 is operable to be secured to the top of a beverage can 200 (as shown in FIG. 4) by snapping onto the rim of the can. The rim section 310 in this example includes an outer surface that begins at the lower edge of an outer skirt 313. The outer surface of the rim section 310 in this example extends up an outside area of the beverage can, over the rim, and slopes downwards towards the central panel of the beverage can top and over a countersink groove inside the rim of the beverage can top. The rim section 310 ends at an inner edge that joins in this example to an outer lower edge of the removable central cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com