Joining system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

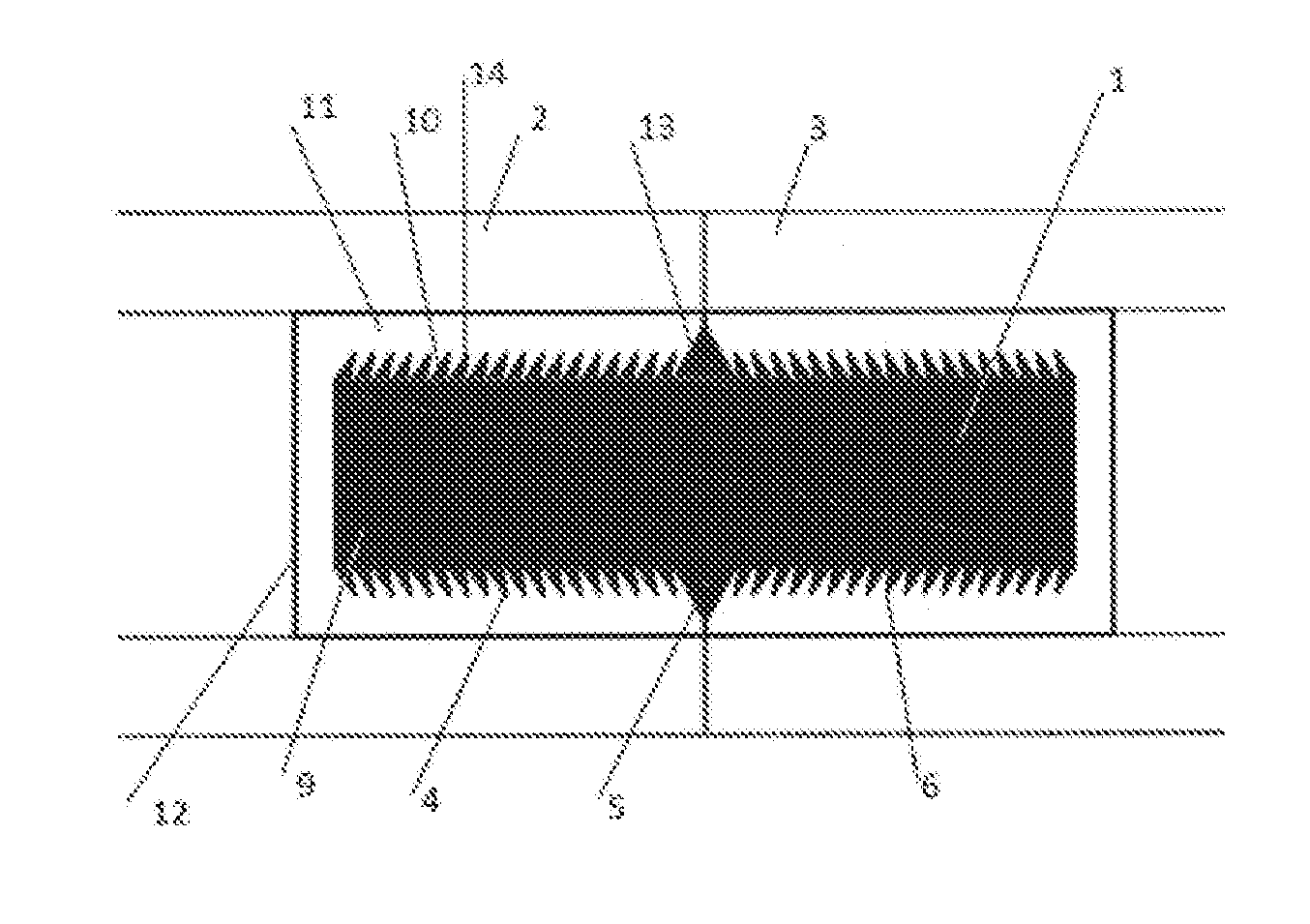

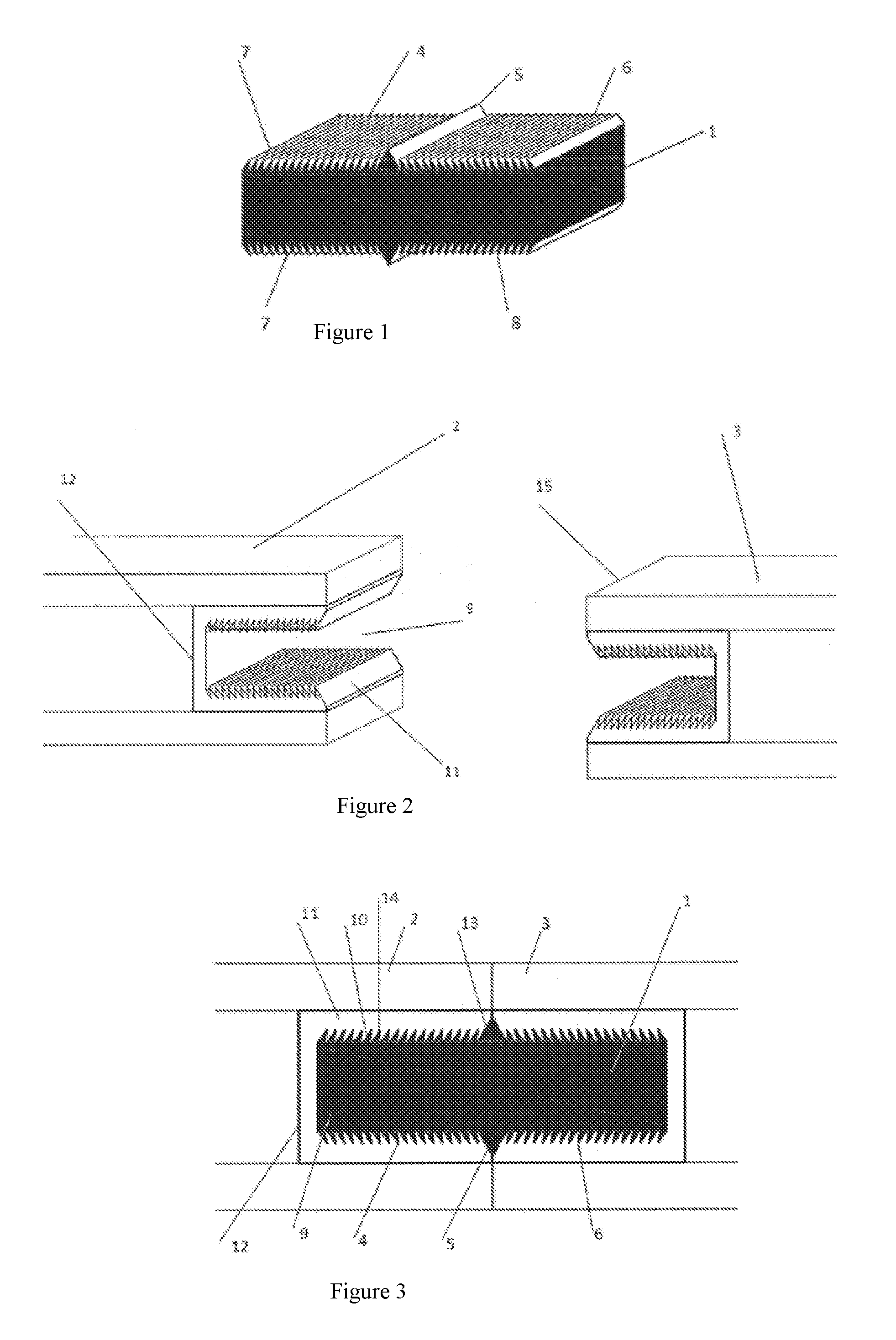

[0025]FIG. 1 shows a joining system comprising a locking device 1 and first and second elements 2, 3 to be joined by the locking device 1.

[0026]The locking device 1 has a first end section 4, a centre section 5, and a second end section 6, where the first and second end sections 4, 6 extend in opposite directions from the centre section 5. In a preferred embodiment, the locking device 1 has substantially the shape of a right parallelepiped. I.e., the locking device 1 is shaped as a right-angled block having six sides. Two first opposing sides have a mutually identical shape while the adjacent two, second opposing sides also have a mutually identical shape. The shape of the second opposing sides could be identical to that of the first opposing sides. However, it could also be different in terms of dimensions. The remaining two third opposing sides of the block can also be described as the short ends of the block. The block preferably has an elongated shape.

[0027]However, the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com