Device and method for painting curved outer surfaces of an aircraft

a technology for aircraft and outer surfaces, applied in process and machine control, program control, instruments, etc., can solve the problems of affecting the and requiring a very long production time. , to achieve the effect of shortest production time and durable application of high-quality picture moti

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

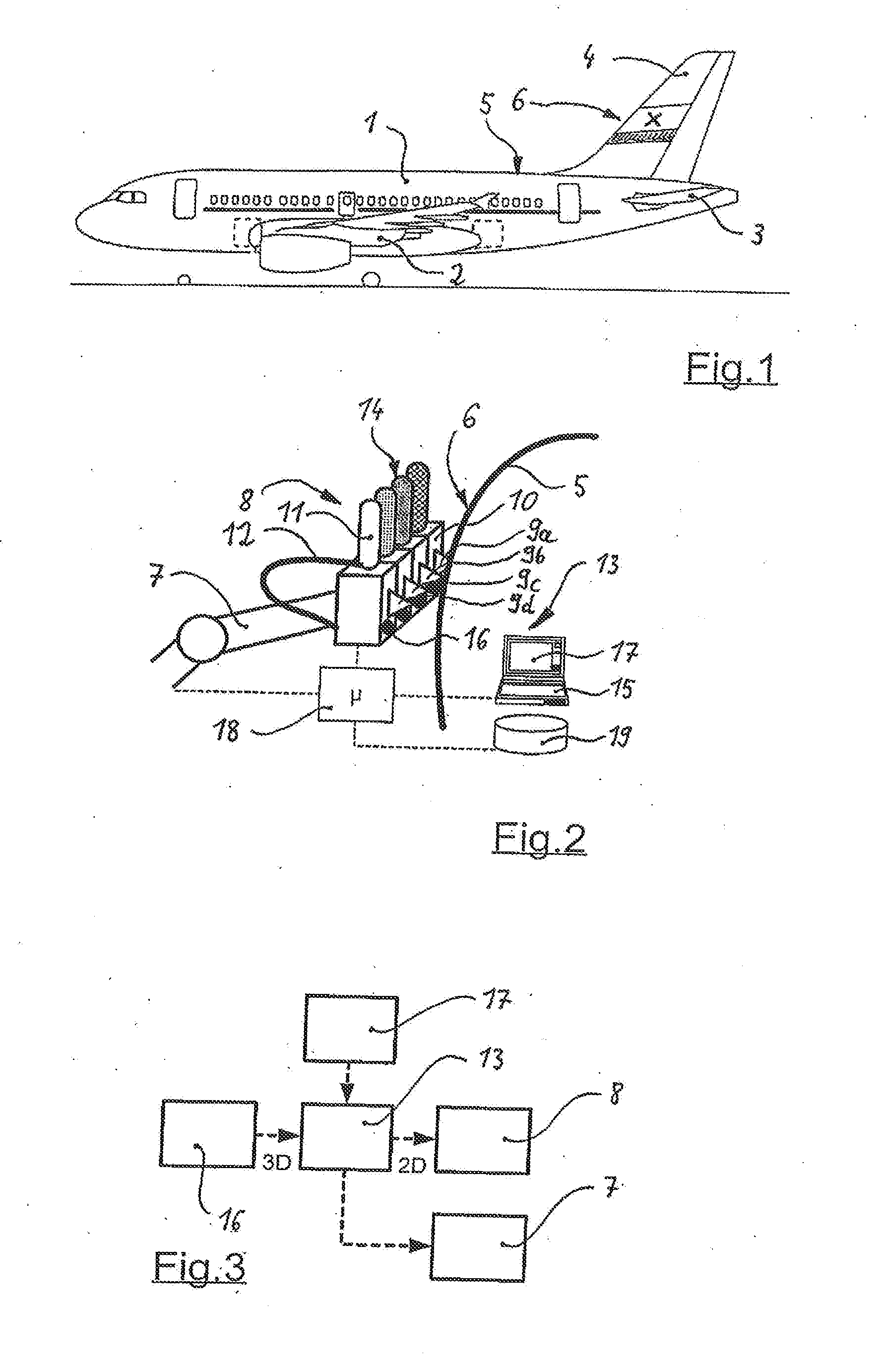

[0022]According to FIG. 1, an aircraft—that is realized in the form of a passenger aircraft-features a fuselage 1, on which a wing 2 with engines is laterally arranged. The rear side of the fuselage 1 features an elevator unit 3, as well as a rudder unit 4 that protrudes upward from the fuselage 1 by a significant distance.

[0023]In this exemplary embodiment, the outer surface 5 of the rudder unit 4 is provided with a photo-realistic picture motif 6 that consists of many color gradations. The outer surface 5 of the rudder unit 4 is essentially curved in one plane, onto which the picture motif 6 is automatically applied in the form of PUR aircraft paint with the aid of the device described below.

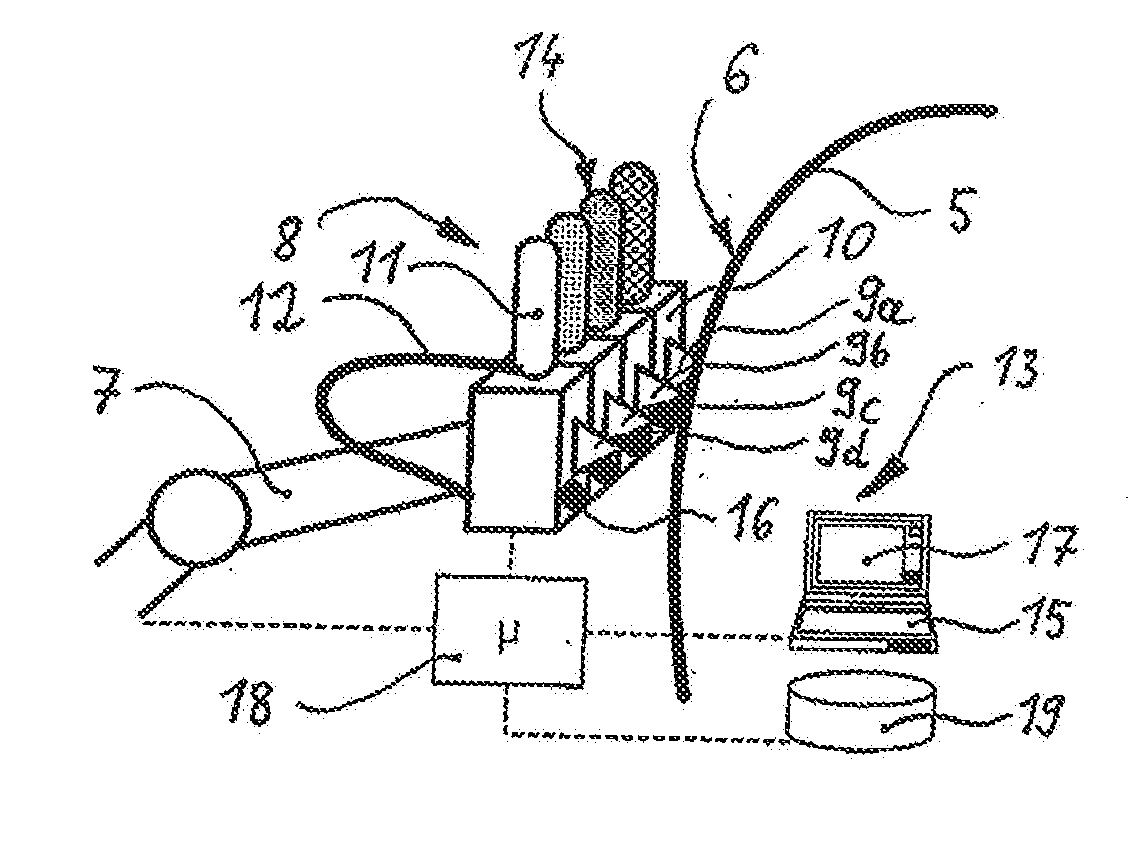

[0024]According to FIG. 2, the device for painting the—only sectionally illustrated—outer surface 5 essentially consists of a spatially adjustable positioning device 7, on which a paint applicator 8 is arranged, wherein the positioning device 7 and the paint applicator 8 are driven along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com