Connection Assembly For Fan Blades Of A Ceiling Fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

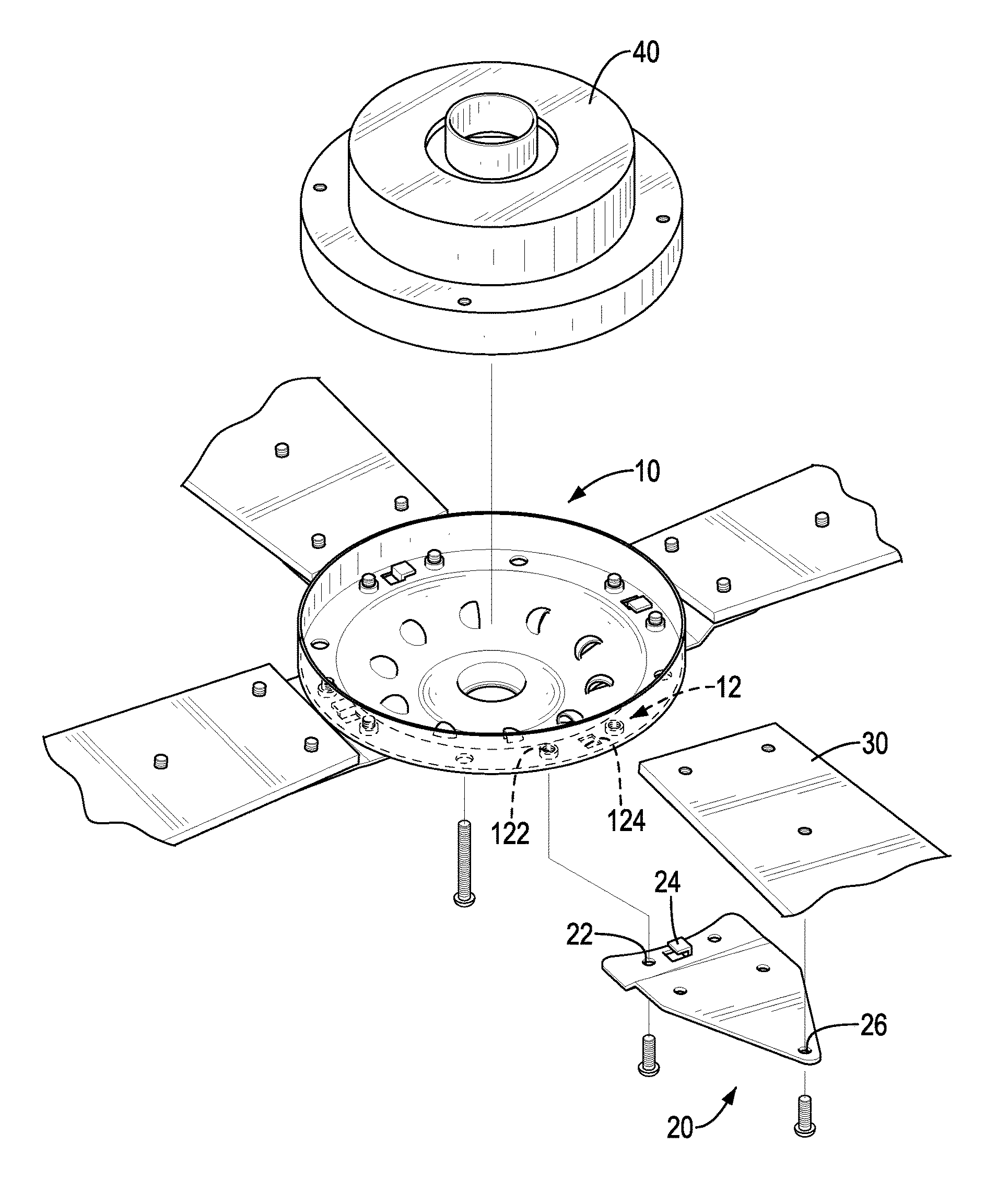

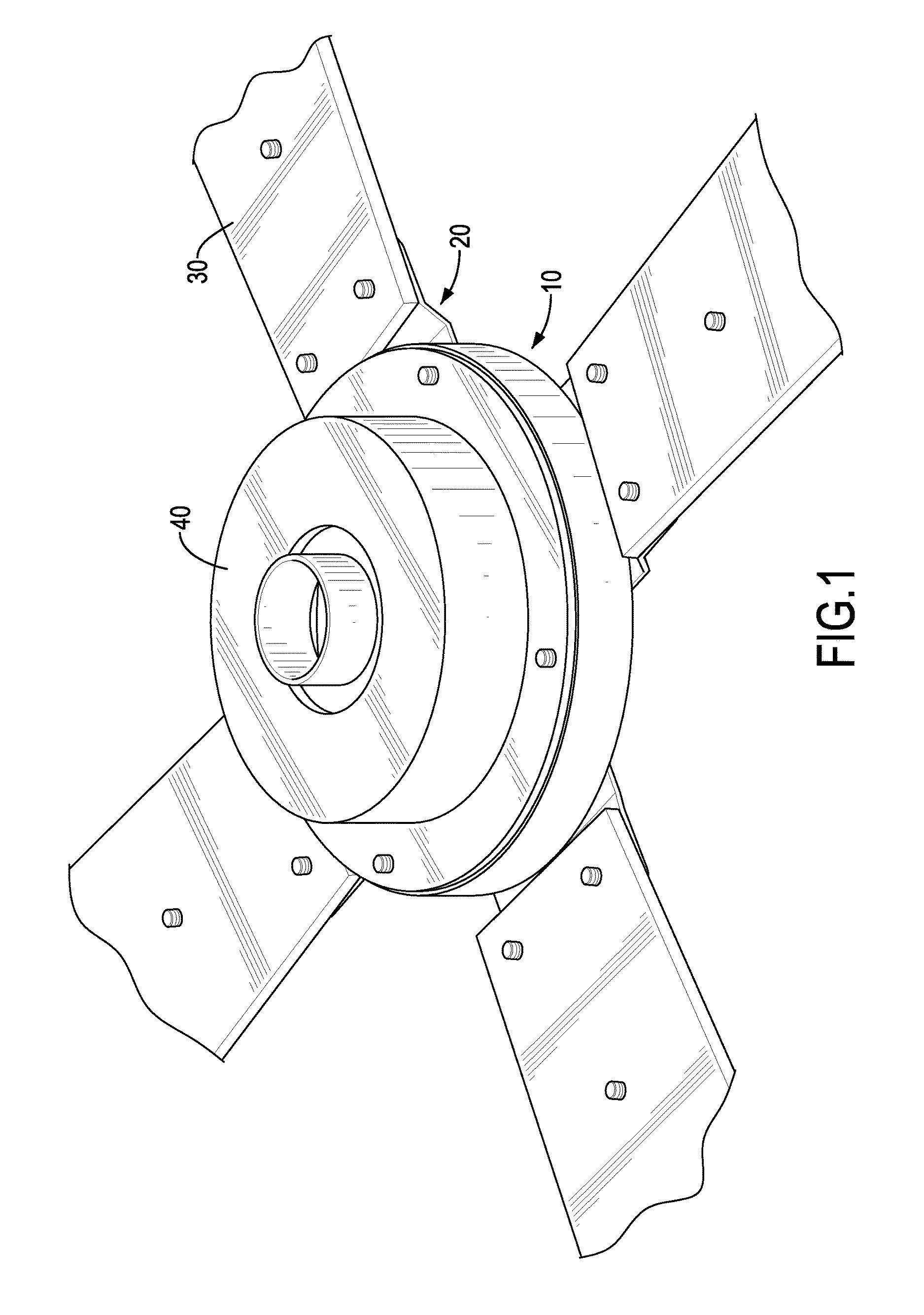

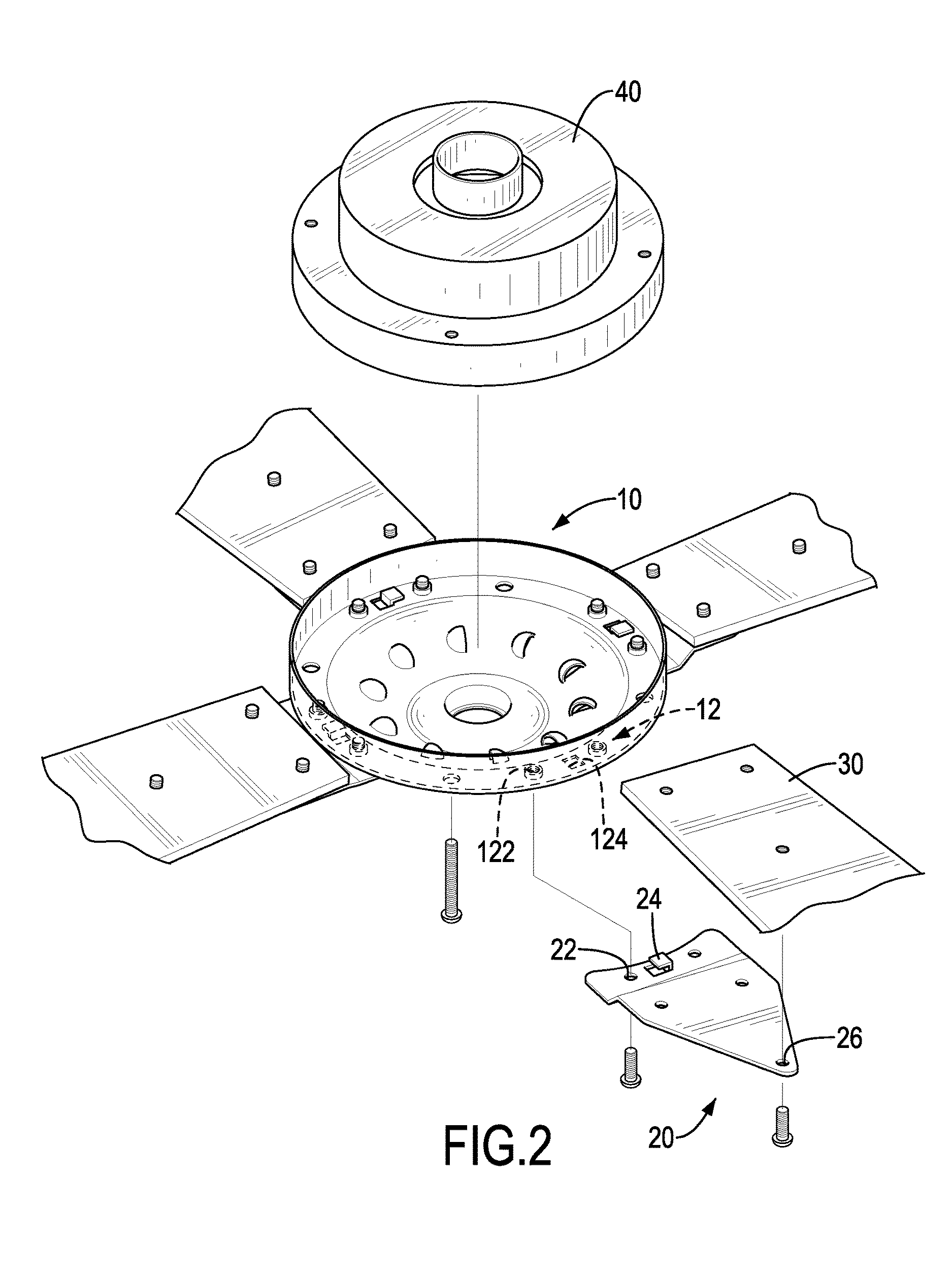

[0014]With reference to FIGS. 1 to 3, a connection assembly for fan blades of a ceiling fan in accordance with the present invention comprises a housing 10, multiple connection tabs 20, and multiple fasteners 50.

[0015]The housing 10 may be formed as a round disk, and has a radial direction, a periphery, and multiple mounting hole sets 12. The mounting hole sets 12 are arranged around the housing 10 at intervals and are adjacent to the periphery. Each mounting hole set 12 comprises multiple mounting holes 122 and a hook hole 124. The mounting holes 122 may be threaded holes or through holes.

[0016]The connection tabs 20 are connected respectively with the mounting hole sets 12. Each connection tab 20 comprises multiple connecting holes 22, a hook 24, and multiple blade-fastening holes 26. The connecting holes 22 are defined through the connection tab 20 at positions adjacent to an end of the connection tab 20 and are aligned respectively with the mounting holes 122 of a corresponding ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap