Base material for printed interconnect boards and manufacturing method of printed interconnect boards

a technology manufacturing methods, which is applied in the manufacture of printed circuits, metallic pattern materials, printed circuit details, etc., can solve the problems of reduced size of printed interconnect boards used in devices, inability to generate printed interconnect boards as products, and remarkably dense interconnect density, so as to reduce the variation of plating film thickness, eliminate individual differences in product performance, and enhance productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

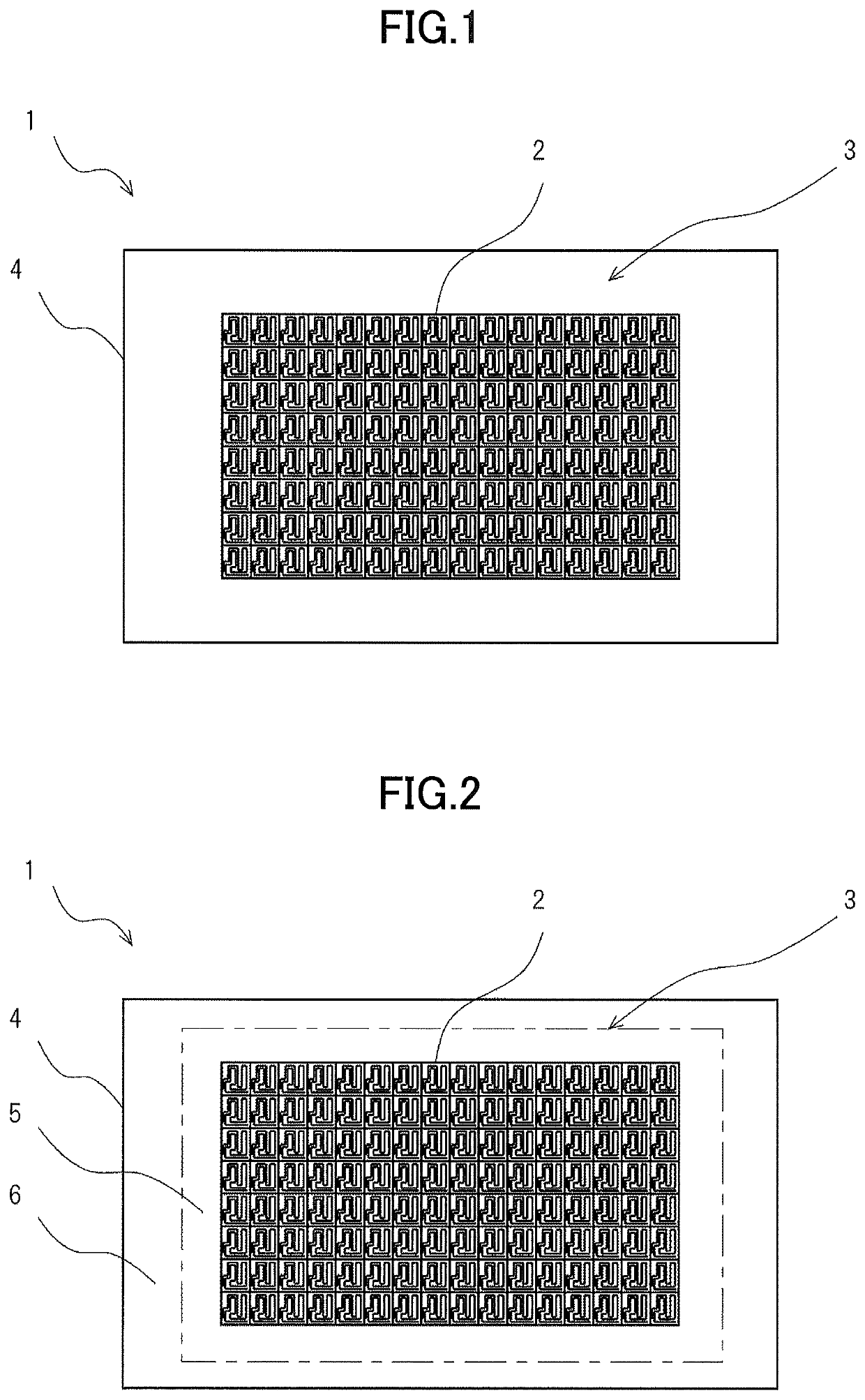

[0029]A base material 1 for printed interconnect boards according to an aspect of the present invention includes a product 3 in which a plurality of interconnect board pieces 2 are arrayed and includes an outer frame region 4 surrounding the product 3, as illustrated in FIG. 1. The outer frame region 4 does not include interconnect board pieces 2, and is separated and removed from the product 3 when the interconnect board pieces 2 are obtained as printed interconnect boards. The interconnect board pieces 2 and the base material 1 for printed interconnect boards are both formed to be substantially rectangular in a plan view, and several tens to several hundreds of interconnect board pieces 2 are disposed on the base material 1 for printed interconnect boards.

[0030](Product)

[0031]The product 3 is composed of the plurality of interconnect board pieces 2 that are regularly arrayed. Small printed interconnect boards manufactured in such a configuration are often small coils or the like, ...

second embodiment

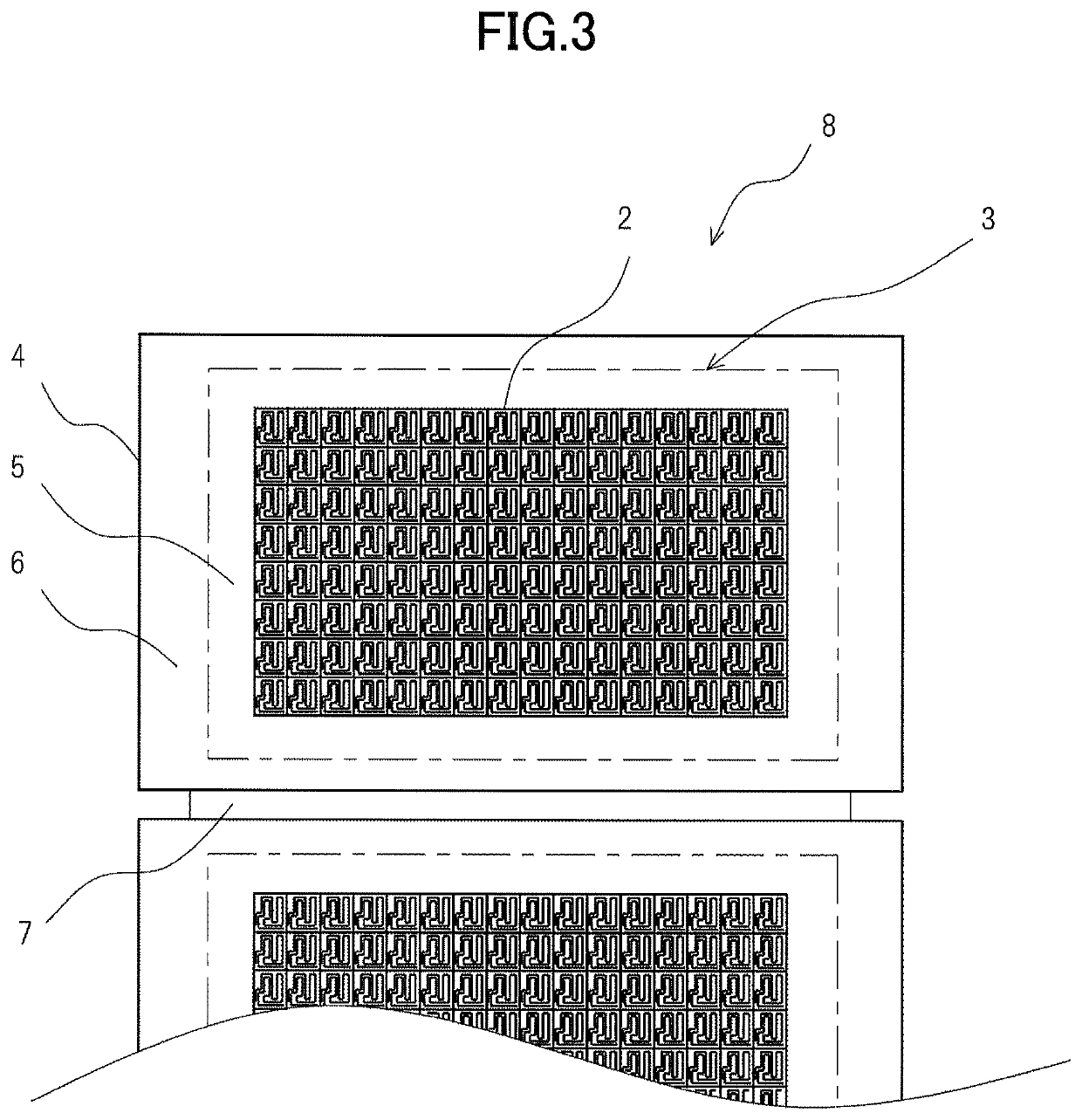

[0047]Next, a base material 8 for printed interconnect boards according to one aspect of the present invention will be described. As illustrated in FIG. 3, the base material 8 for printed interconnect boards has a large sheet shape having a plurality of products 3 and outer frame regions 4 (hereinafter, the base material 8 for printed interconnect boards may be referred to as the base material sheet 8). The base material sheet 8 includes connection regions 7 that connect the outer frame regions 4 next to each other. Because the base material 8 is formed to be substantially rectangular in a plan view, and several tens to several hundreds of interconnect board pieces 2 are disposed in one product 3, several hundreds of printed interconnect boards are manufactured at once from the base material sheet 8.

[0048](Connection Region)

[0049]A connection region 7 connects an outer frame region 4 and another outer frame region that is in communication with this outer frame region 4. That is, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| conductive layer area rate | aaaaa | aaaaa |

| area rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com