Weight plate gap adjustment device for weight training equipment

a technology of weight training equipment and gap adjustment device, which is applied in the direction of muscle exercise device, gymnastic exercise, sport apparatus, etc., can solve the problems of gap between the locking pin, the weight plate and the traction shaft, exerting force but not being able to move, and poor fitness operation, so as to improve the operating feeling and movement intuition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

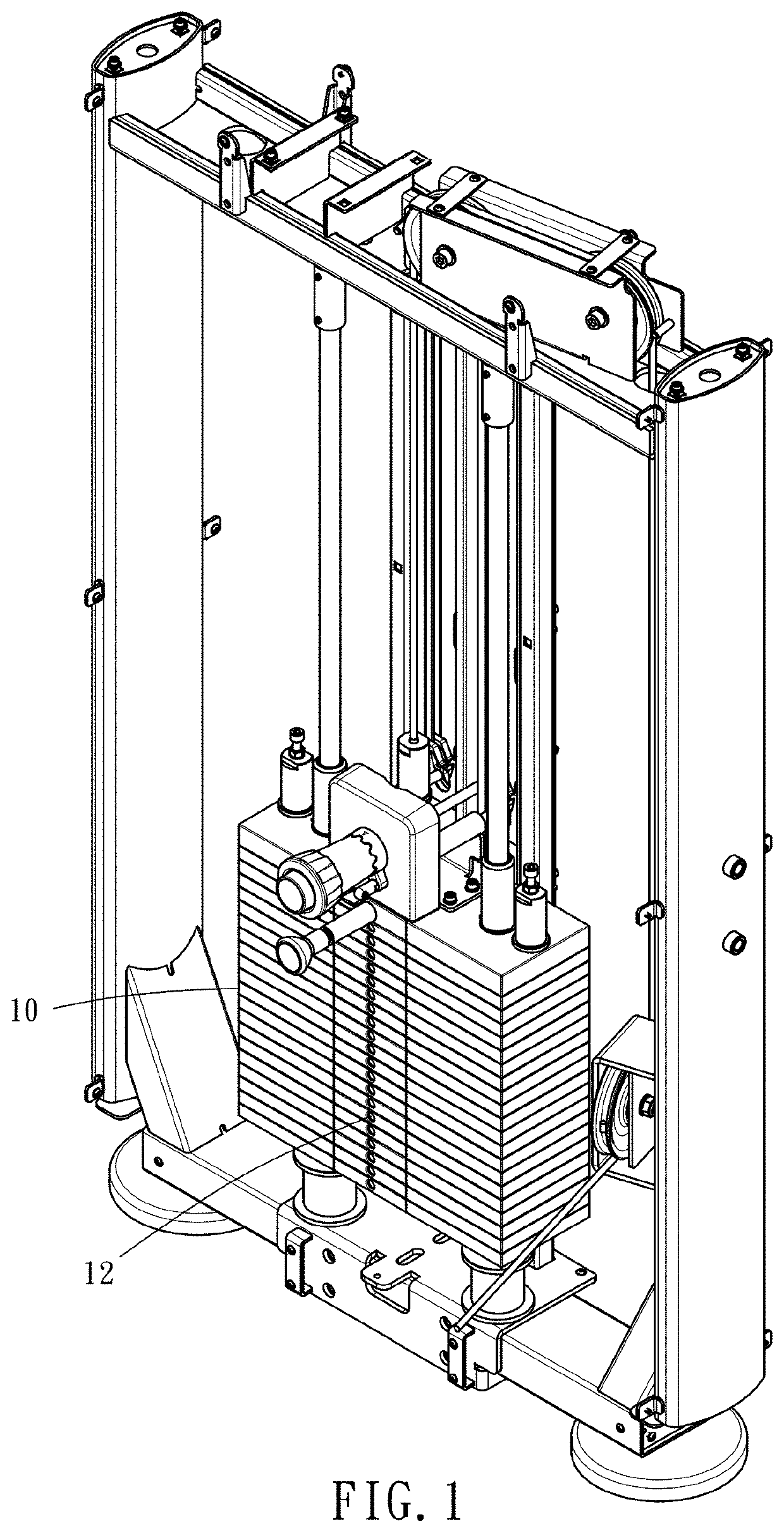

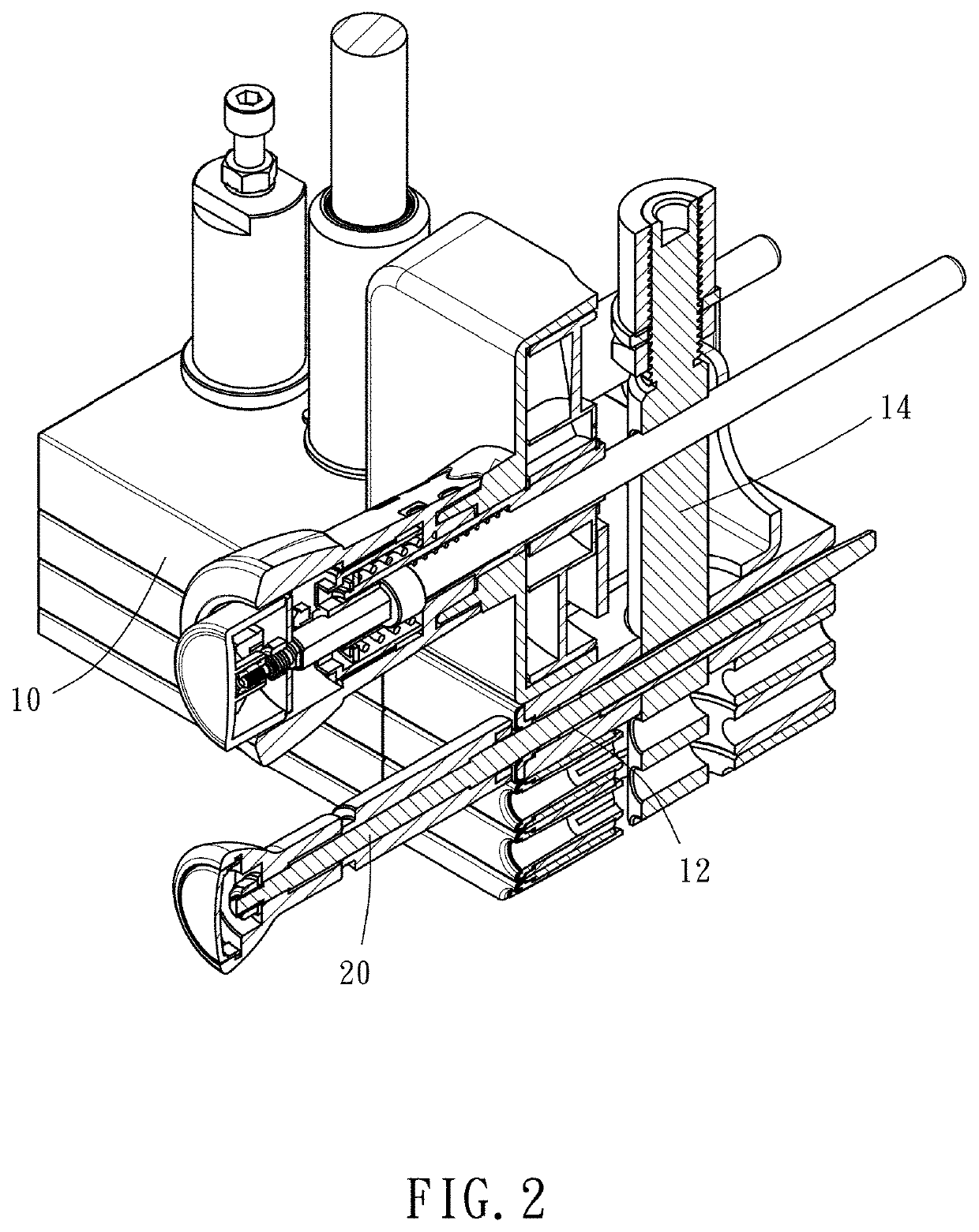

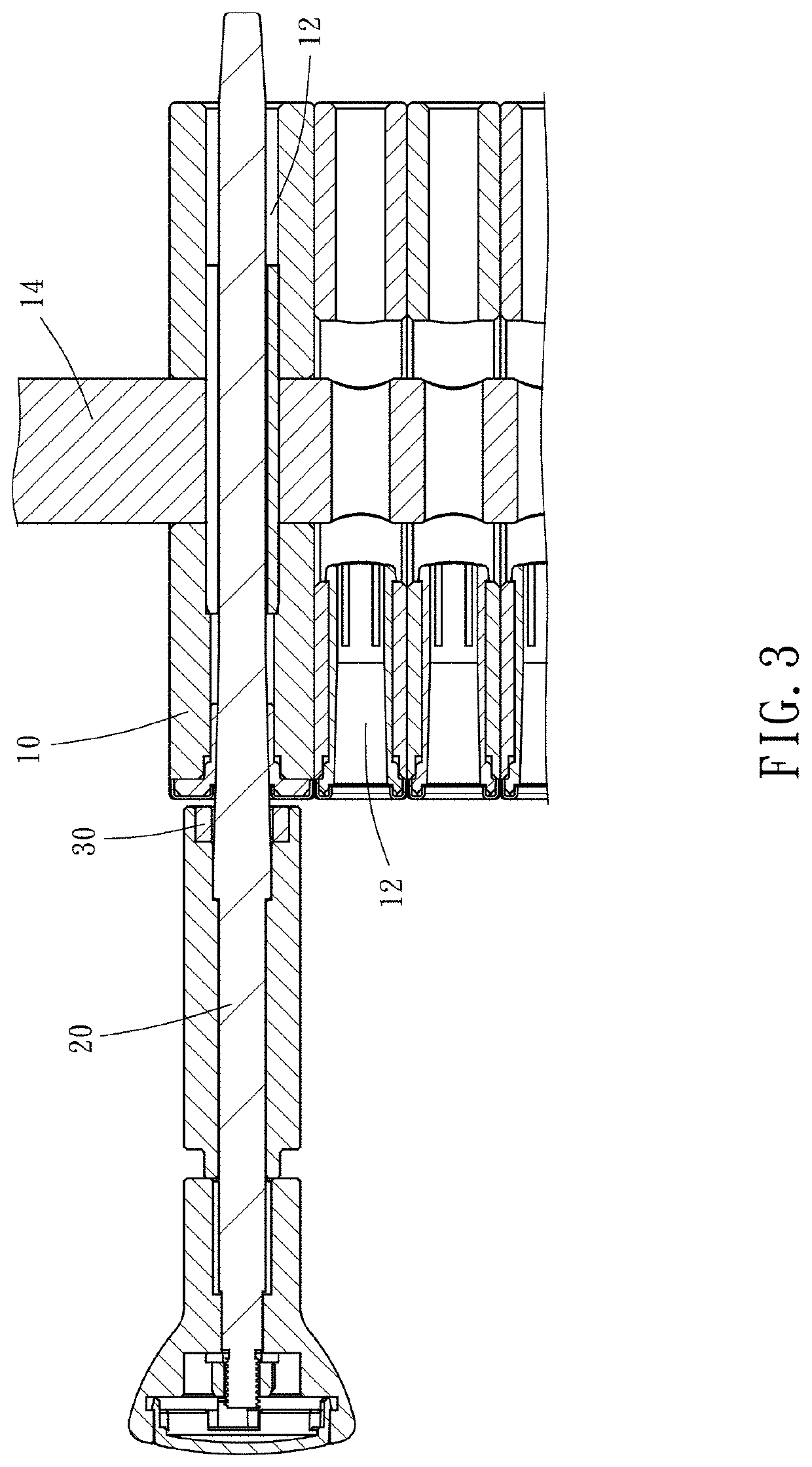

[0014]Hereinafter, the technical content and features of the present invention will be described in detail by enumerating preferred embodiments with drawings. The weight plate gap adjustment device of weight training equipment provided by the present invention can be widely used in various fitness equipment with weight training boxes. Those skilled in the art can understand that the explanatory terms of this embodiment belong to the upper-level description that does not limit the application field. For example, the material or shape terms include but are not limited to the material or shape specified by the description content, and the position terms include but are not limited to setting, proximity, connect, or adjacency. The term “one” for the quantity of each component includes one and more than one component quantity. The directional adjectives mentioned in the content of this specification, such as “upper”, “lower”, “inner”, “outer”, “top”, “bottom”, etc. are only exemplary des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com