Thermal overload relay

a relay and overload technology, applied in relays, circuit-breaking switches, snap-action arrangements, etc., can solve problems such as problems in operational characteristics of the above-described conventional structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

An embodiment of the present invention will be described with reference to the drawings. The members in FIGS. 1 to 3 that are the same as in the conventional example are denoted by the same reference numerals and description thereof is thus omitted.

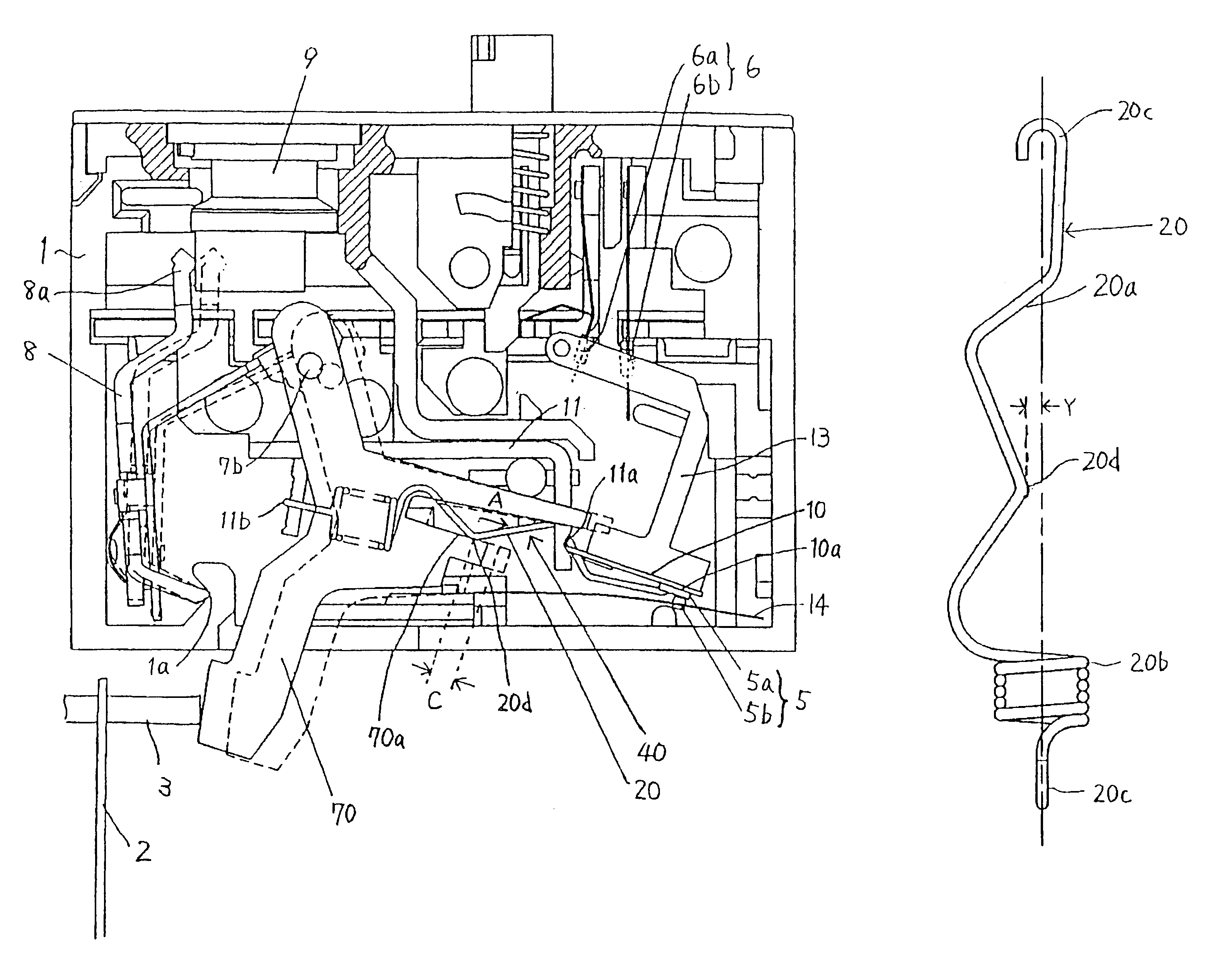

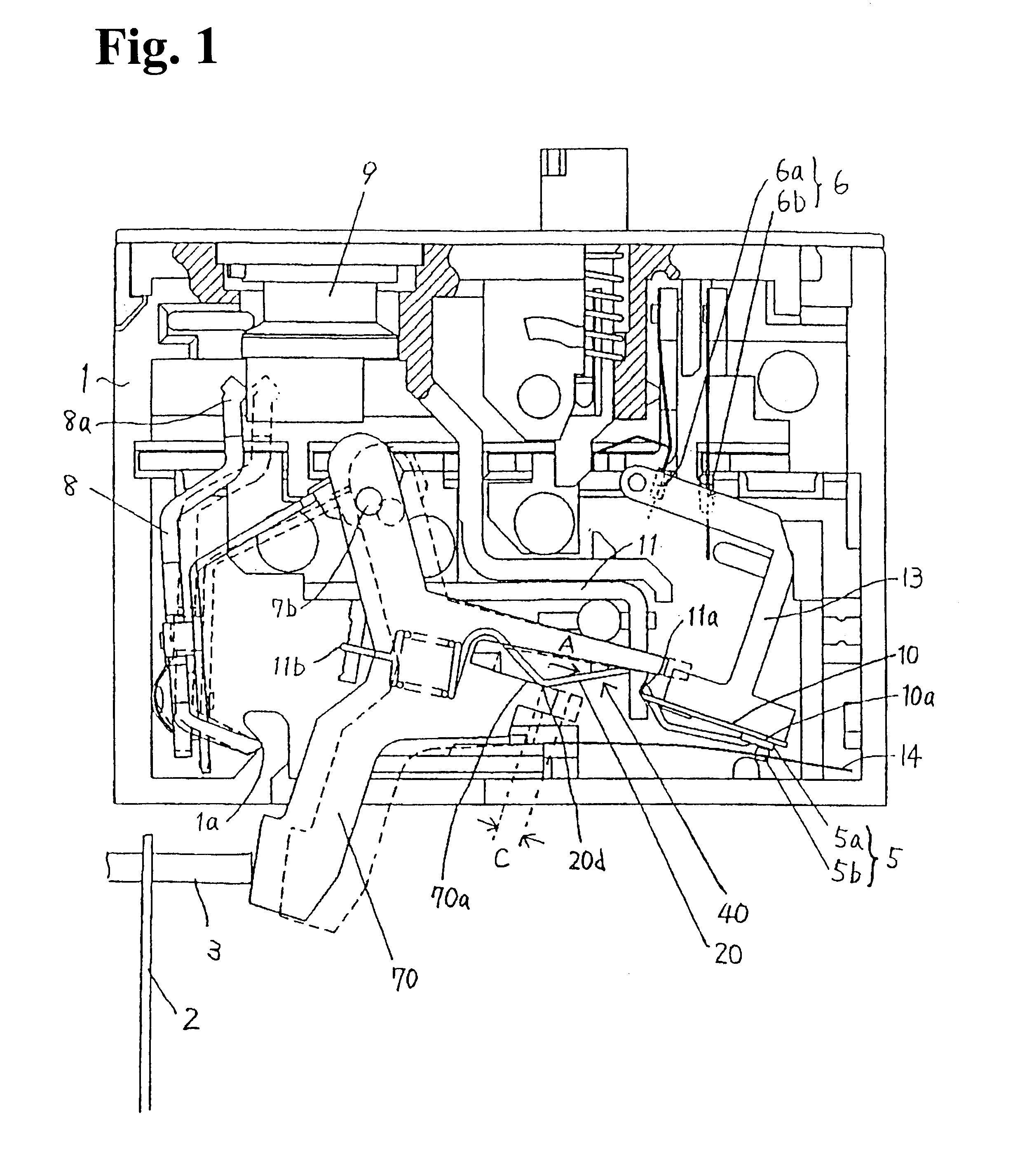

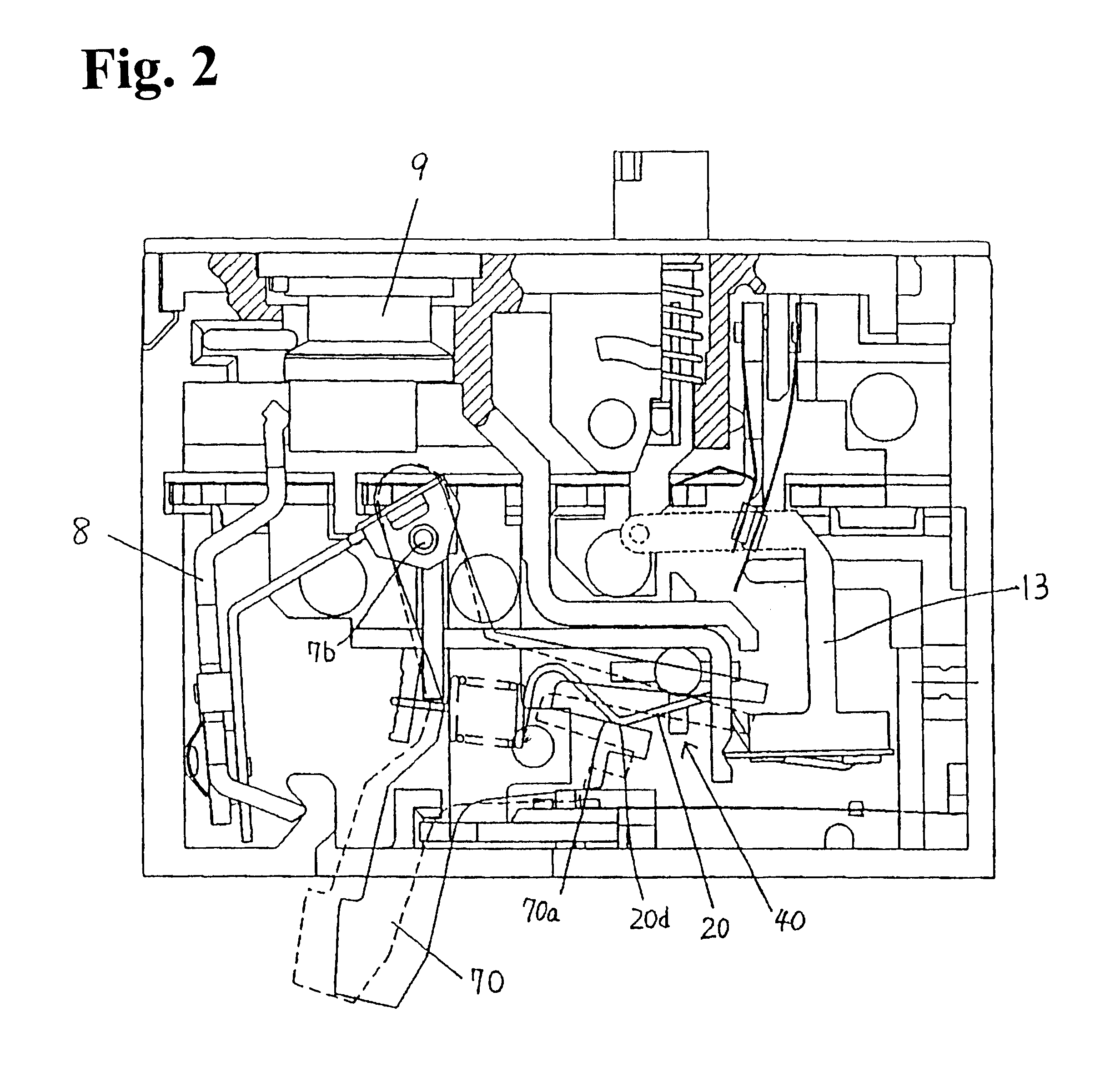

FIG. 1 is a view of an internal mechanism of a thermal overload relay showing a steady or normal state, and FIG. 2 is a view of the internal mechanism of the same relay showing an overload state. FIG. 3 is a perspective view of a tension spring, shown in FIG. 1.

The thermal overload relay according to the embodiment shown in the figures is essentially similar to the thermal overload relay shown in FIG. 4, but differs therefrom in that a tension spring 20 extending between a movable plate 10 of an inversion operation mechanism 40 and a spring catching section 11b of a support piece 11 is shaped as shown in FIG. 3, and in that a top portion of a releasing lever 70 that presses the middle of a wire of the tension spring 20 is formed to have a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com