Pendulum valve assembly

a technology of pendulum valves and assembly parts, which is applied in the direction of valve member-seat contacts, mechanical devices, valve operating means/releasing devices, etc., can solve the problem of poor flow control (conductance) in this operating range of the valv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

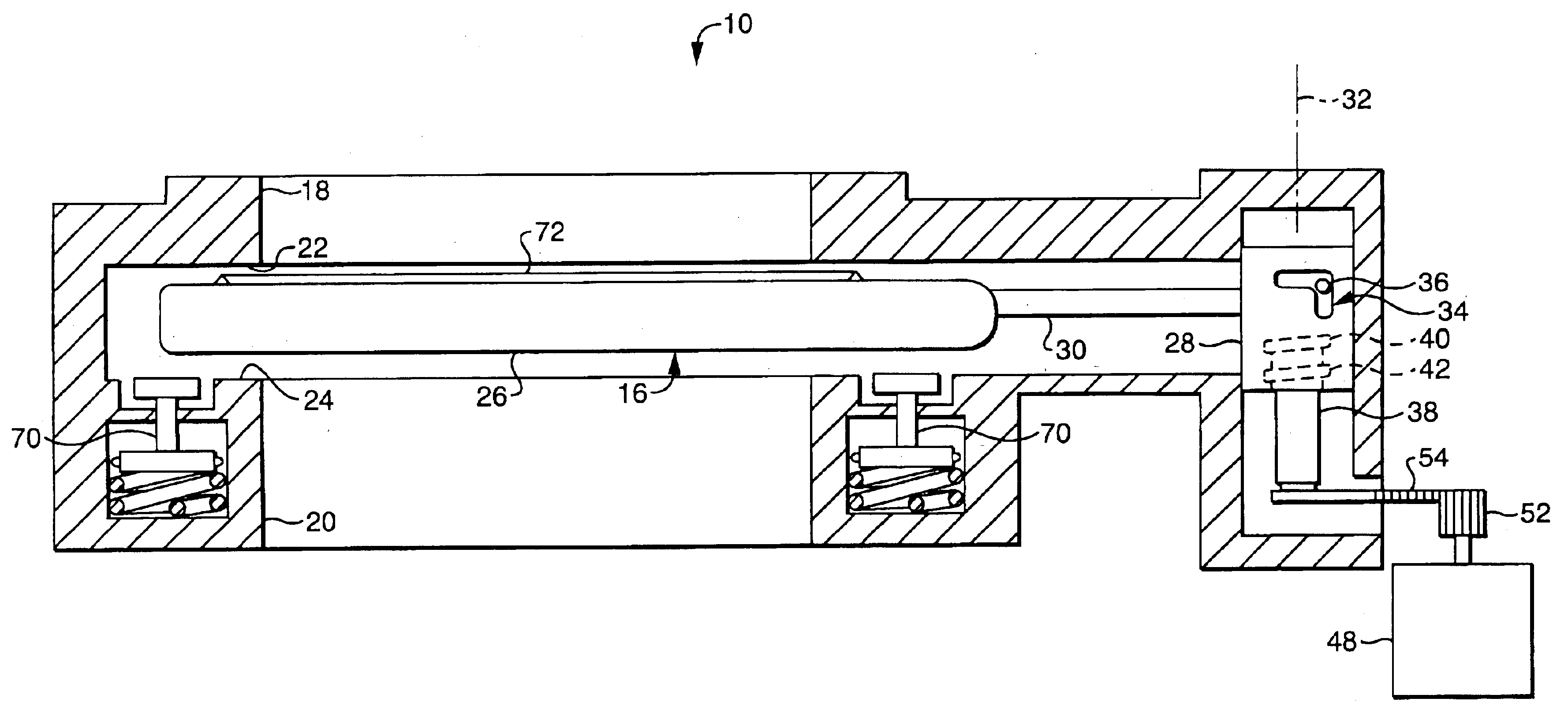

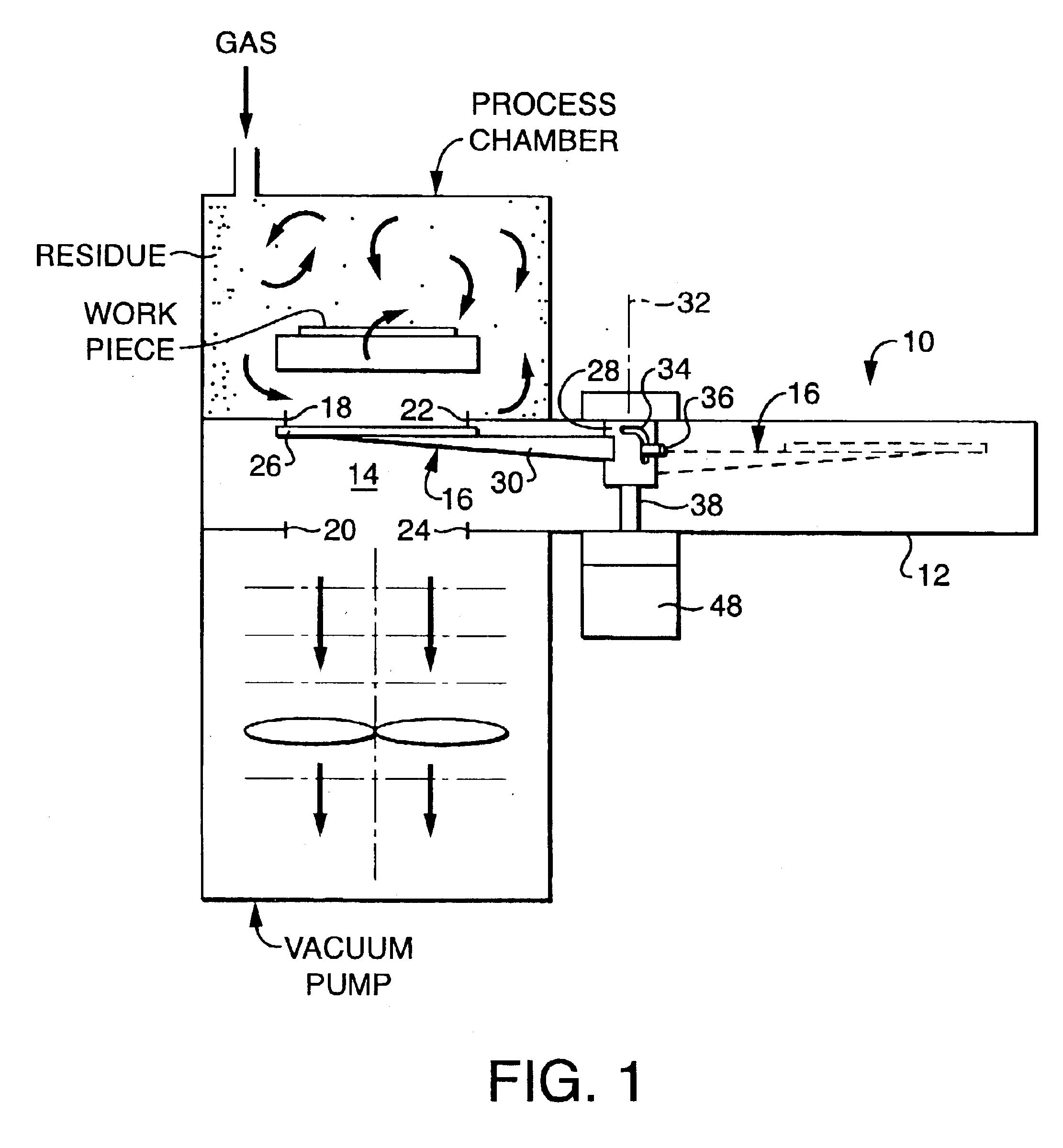

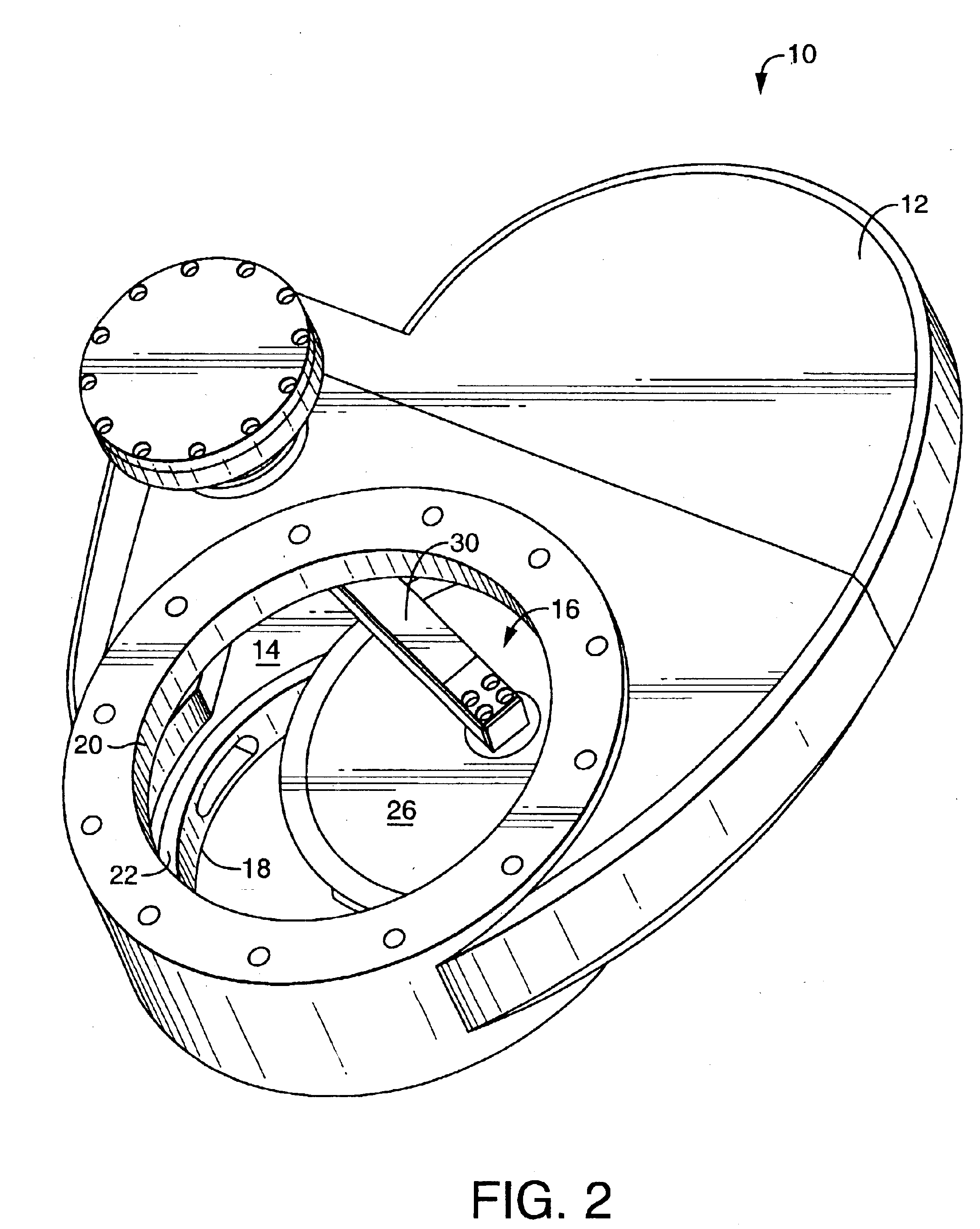

Referring to FIG. 1, an exemplary embodiment of a pendulum valve assembly 10 constructed in accordance with the present invention generally includes a housing 12 defining an interior space 14 containing a pendulum valve 16 and having a pair of opposing openings 18, 20 through which gas can enter and exit the interior space. Valve seats 22, 24 are provided in the interior 14 of the housing 12 around edges of the openings 18, 20. As shown, the pendulum valve 16 includes a valve body 26 which is moved between a completely opened position allowing fluid flow through the opening 18, as shown in broken lines, and a completely closed position preventing fluid flow through the opening 18, as shown in solid lines.

As also shown, the first of the openings 18 of the pendulum valve assembly 10 can, for example, be connected to a process chamber and a second of the openings 20 can be connected to a vacuum pump to form a portion of a high purity gas delivery system, such as those used in semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com