Elastic tab laminate material

A technology of elastic layer and sheet, applied in the field of elastic sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

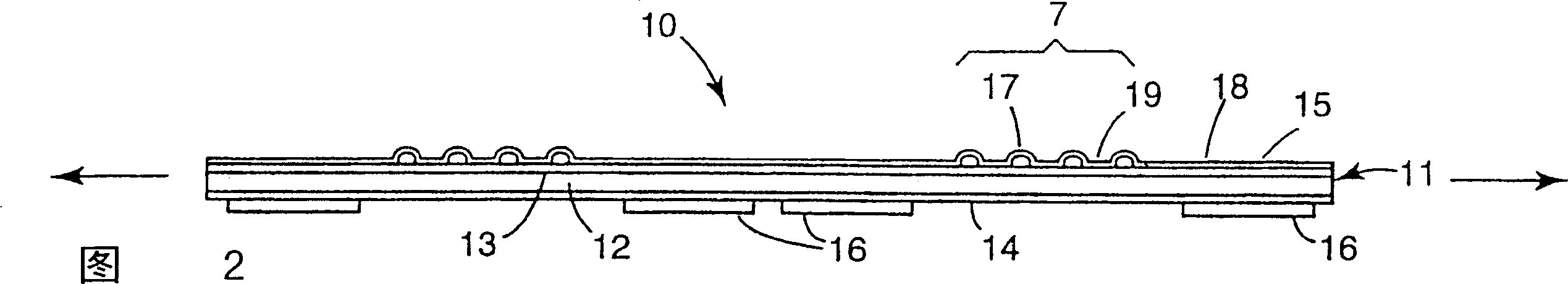

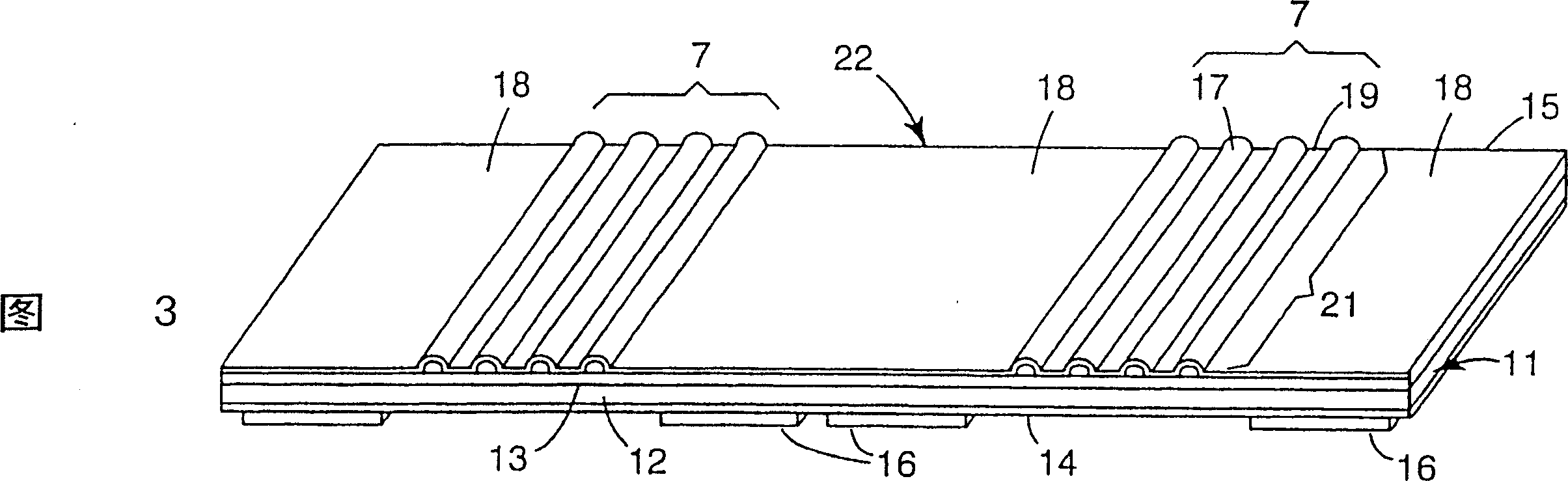

[0121] A nonwoven web / elastomeric film laminate having corrugated regions was prepared by thermal bonding. Film samples 20 shown in Table 1 were laminated at 34 g / m 2 (Manufactured by Avgol Ltd Nonwoven Industries (Holin, Israel) and sold through the sales network of John Cleaver & Assoc. (Wayne, PA)). The nonwoven web was corrugated in-line just prior to lamination in a nip formed by an upper corrugated steel roll (116°C) and a lower corrugated steel roll (149°C), which were machined to The surface of the roller has a plurality of spaced apart circumferential ridges. The plurality of raised spaces formed a 2.54 cm wide corrugated nonwoven web region and a 5.08 cm wide non-corrugated nonwoven web region separating the corrugated region. The corrugation rolls are adjusted so that the plurality of circumferential ridges of the upper roll engages with the plurality of circumferential ridges of the lower roll. The degree of interengagement is adjusted such that the nonwoven fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com