Side mold for gravitational casting of automobile hub

A technology of automobile wheel hub and gravity casting, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of high leaking rate of RIM parts, and achieve the effect of enhancing market competitiveness, reducing leaking rate, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

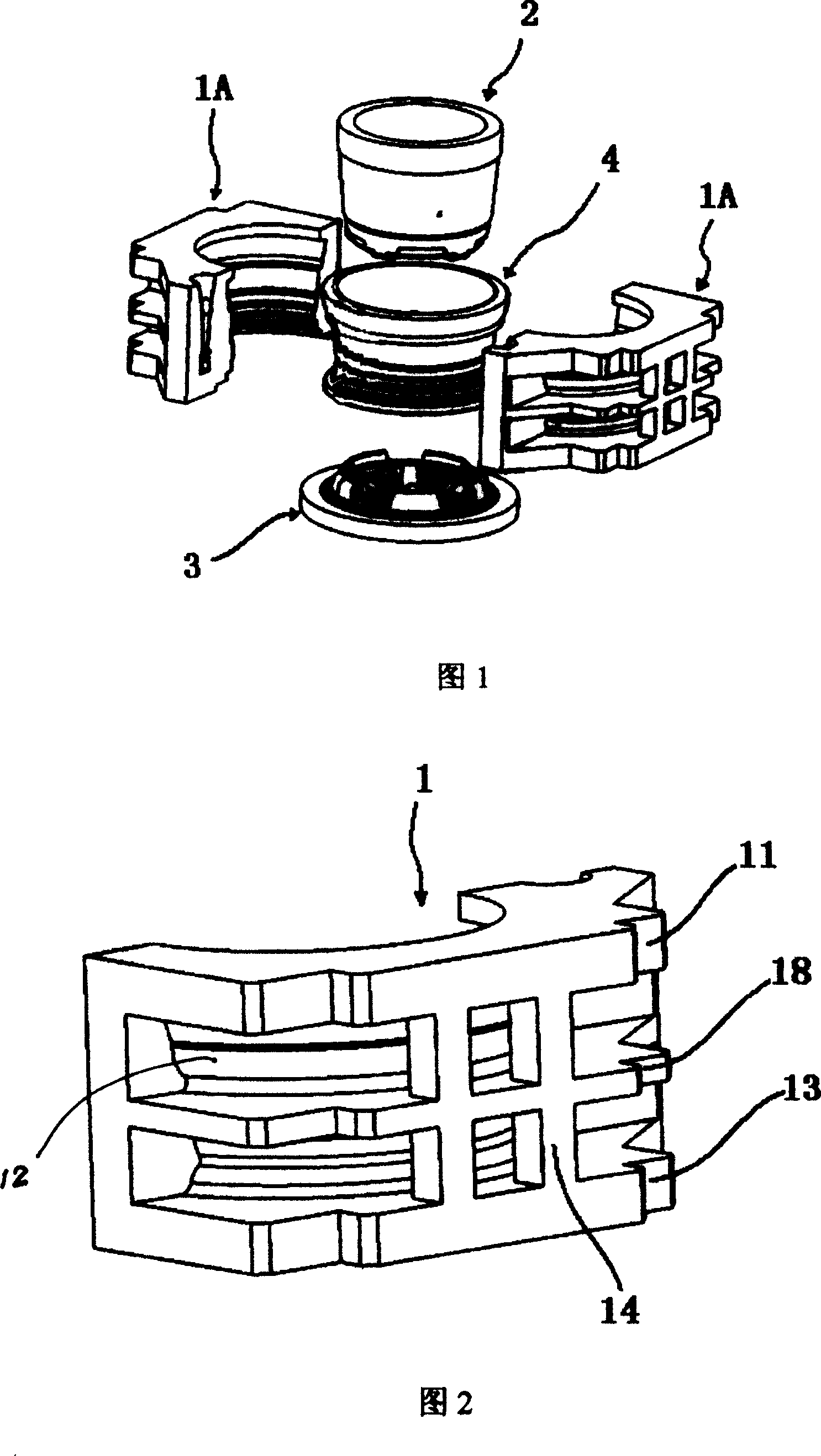

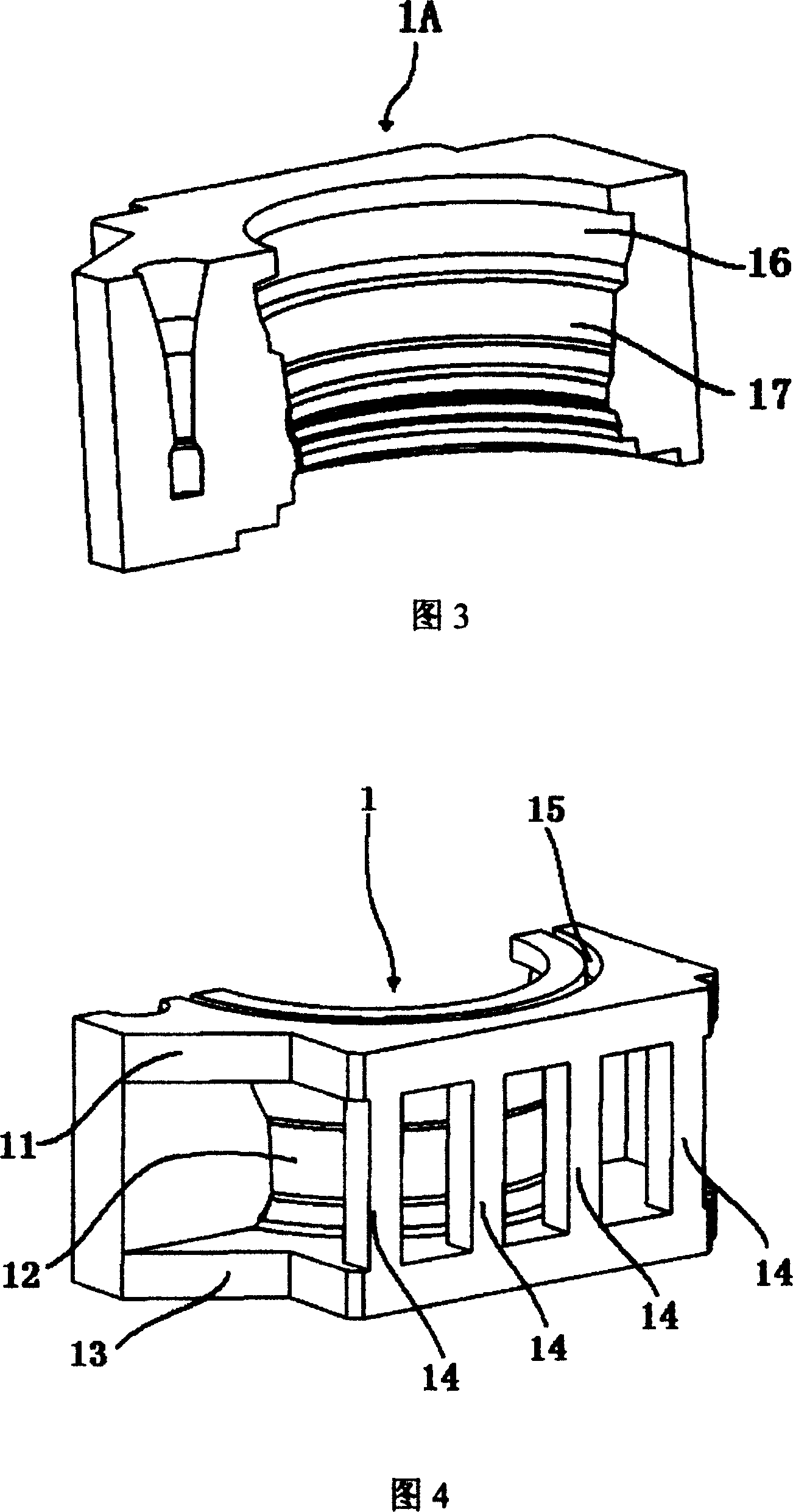

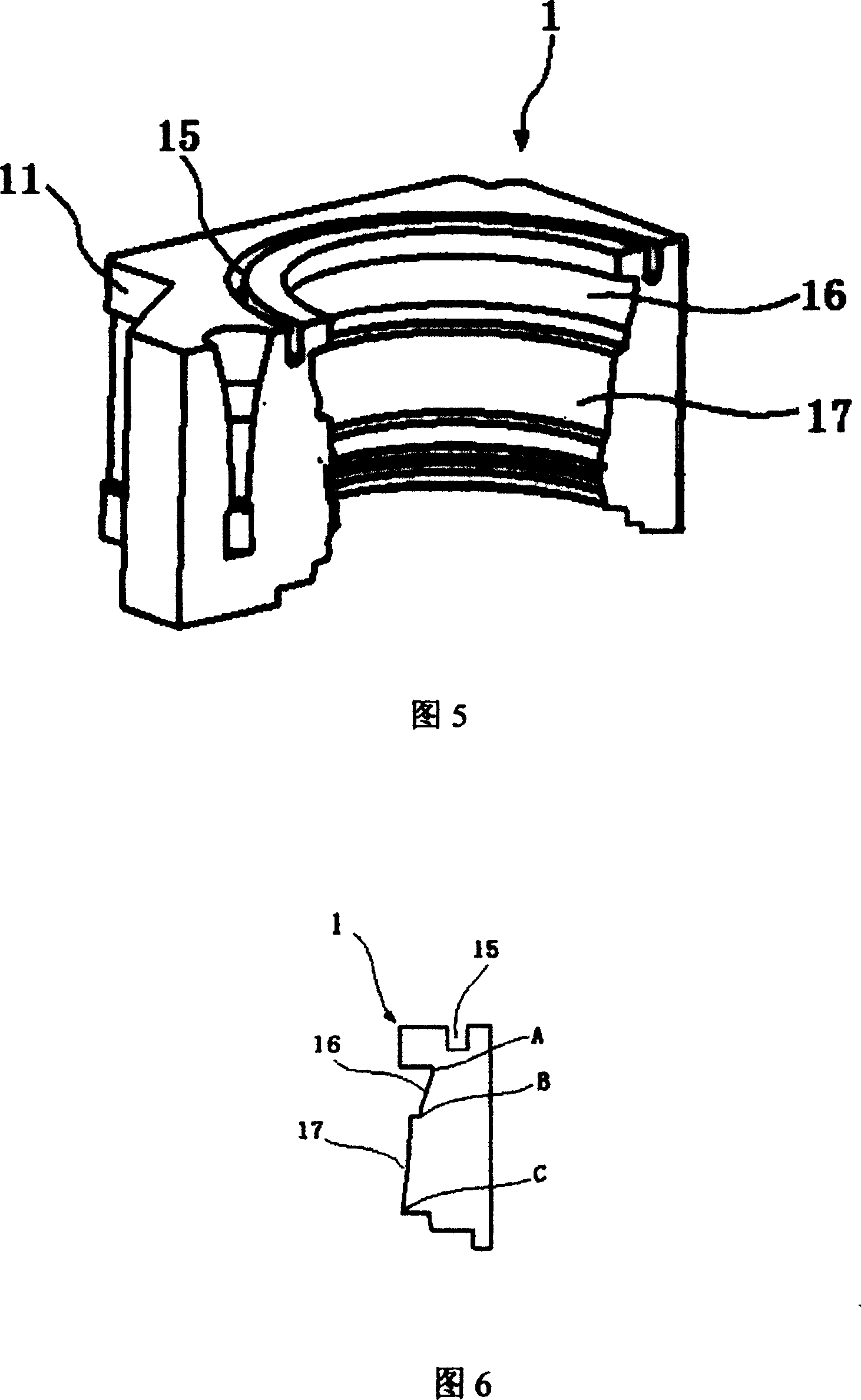

[0025] As shown in Figure 4, a kind of side mold of gravity casting automobile hub is made up of upper rib 11, web 12, lower rib 13, support rib 14, and upper rib 11 is positioned at the top of web 12 and is connected with web 12 is vertical, the lower rib 13 is positioned at the bottom of the web 12 and is perpendicular to the web 12, the supporting rib 14 is positioned between the outer side of the upper rib 11 and the outer side of the lower rib 13, and the number of supporting ribs 14 is 4, And it is vertically connected with the upper rib plate 11 and the lower rib plate 13. The annular groove 15 is located at the inside of the top of the upper rib plate 11 of the side mold, and is located at the side of the side riser 16 .

[0026] As shown in Figure 5, the side riser 16 is located on the lower inner side of the upper rib plate 11, and below the side riser 16 is the BC section of the side mold, which corresponds to the RIM part of the hub, and their relationship can be f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com