Space-precasting translation-emplacing method for bridge construction

A technology for bridge construction and prefabricated beams, which is applied in bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problem of insufficient prefabricated sites for bridge piers, save processing costs and backfill costs, compact site layout, and easy stability Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The construction embodiment of the bridge construction method of the air prefabricated translation in place of the present invention:

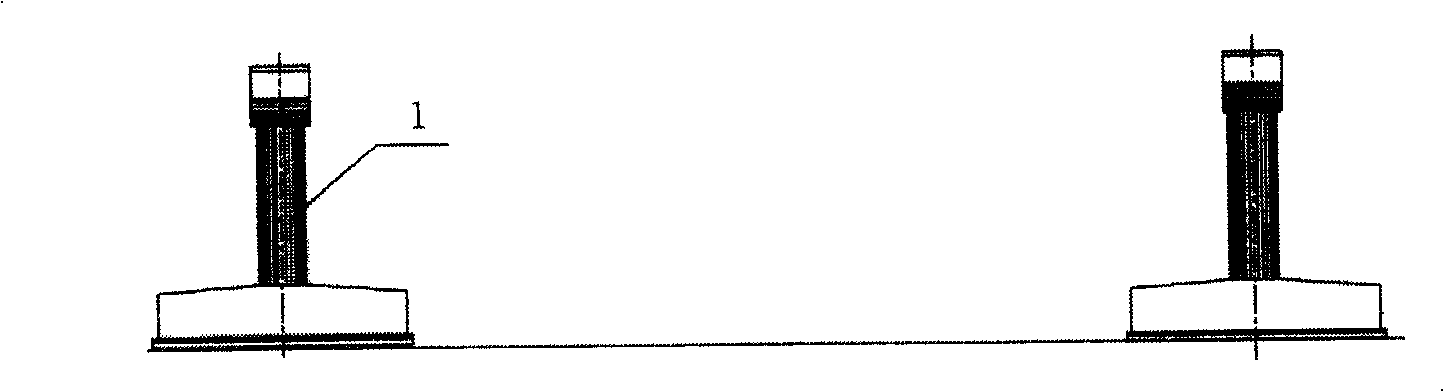

[0038] Step (1) see figure 1 , Construction pier 1, the concrete strength meets the requirements.

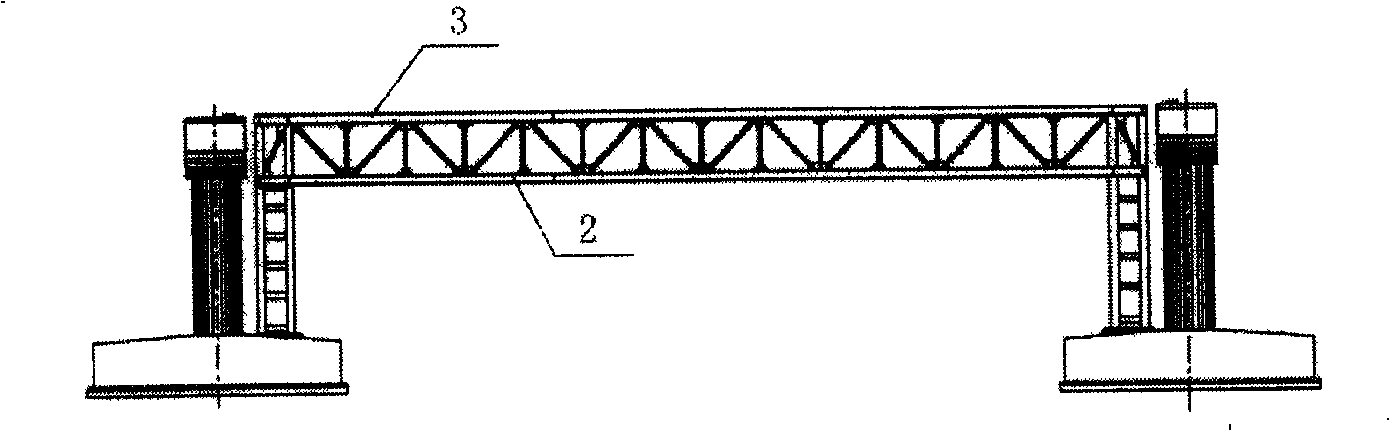

[0039] Step (2) see figure 2 A door-shaped steel truss 2 with the same height as the bridge pier is erected along the bridge between two bridge piers of a certain span. platform3. The specific manufacturing and installation process of the prefabricated platform: first position and set out the line, determine the specific position of the lattice column on the pier foundation on site, use concrete to level the foundation slope locally as the foundation of the column; then process and install the lattice steel column; process The truss beam segments are welded, and finally the steel trusses are assembled.

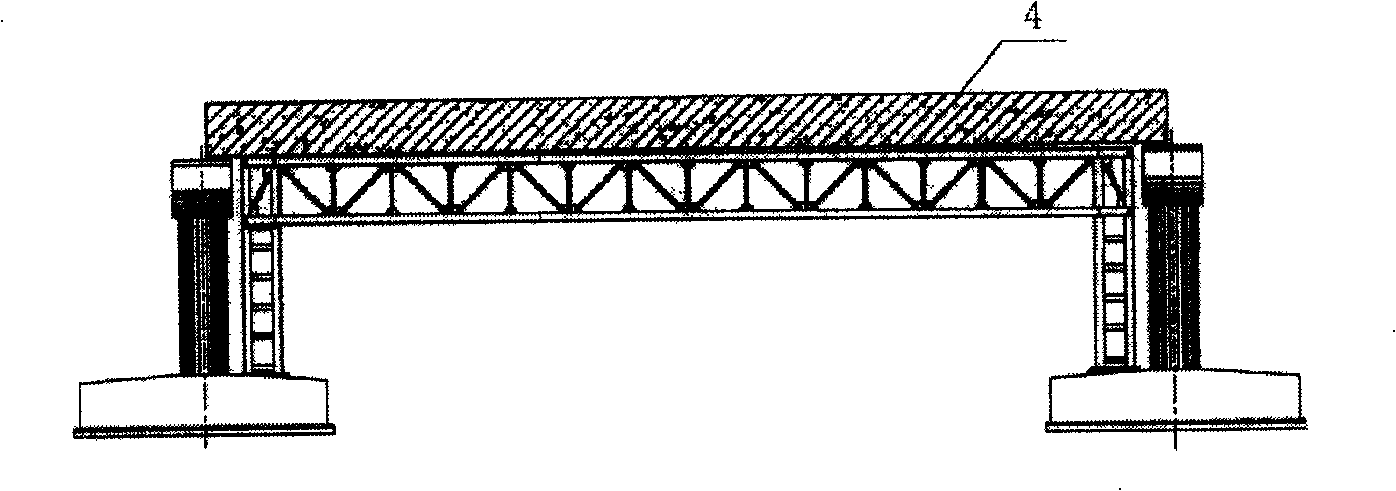

[0040] Step (3) see image 3 , make prefabricated beam 4 on the prefabricated platform; the specific construction process of prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com