Detachable and separable filter element

A decomposed and filter element technology, applied to engine components, liquid fuel feeders, machines/engines, etc., can solve problems that affect the normal and safe driving of vehicles, short service life, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

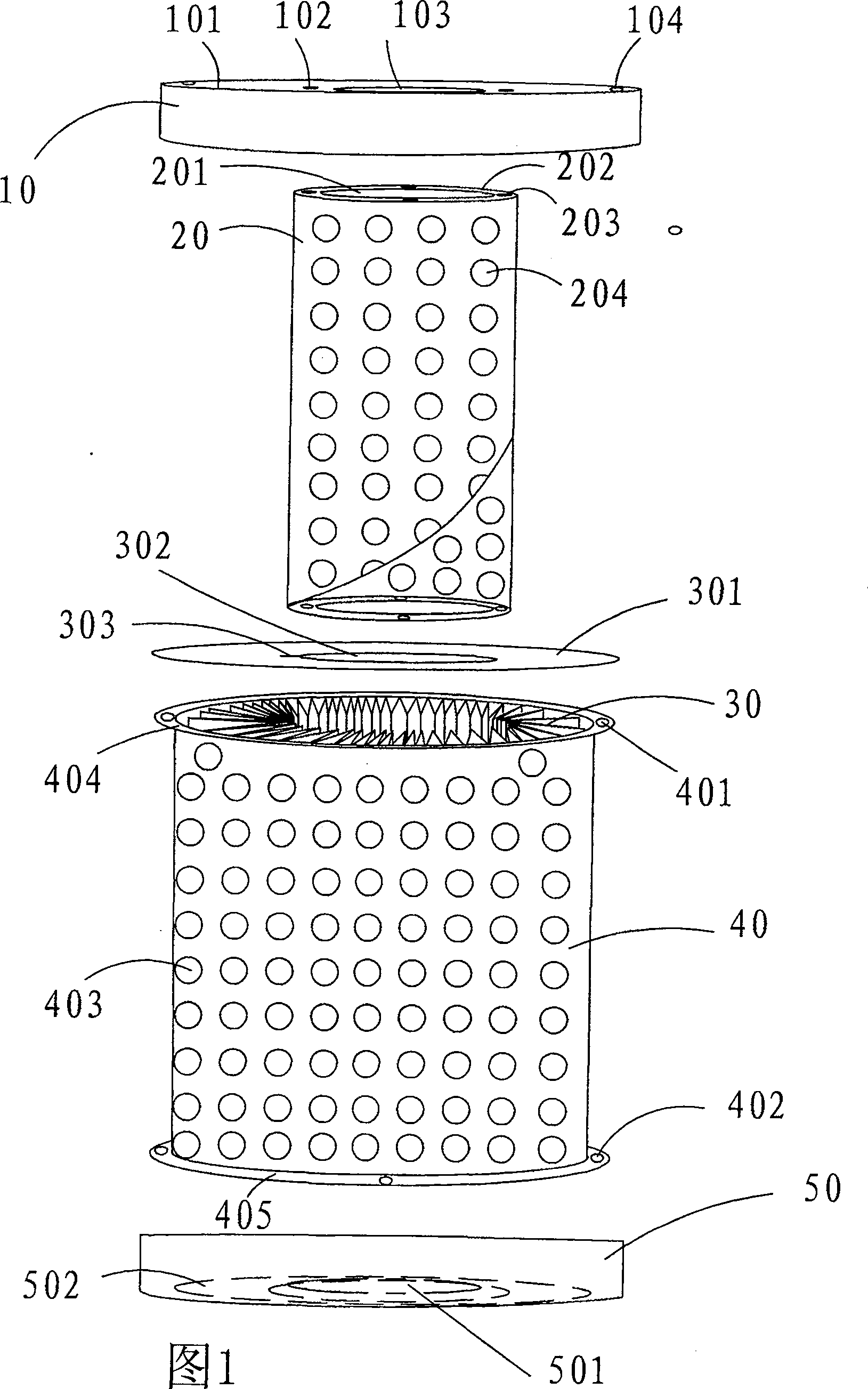

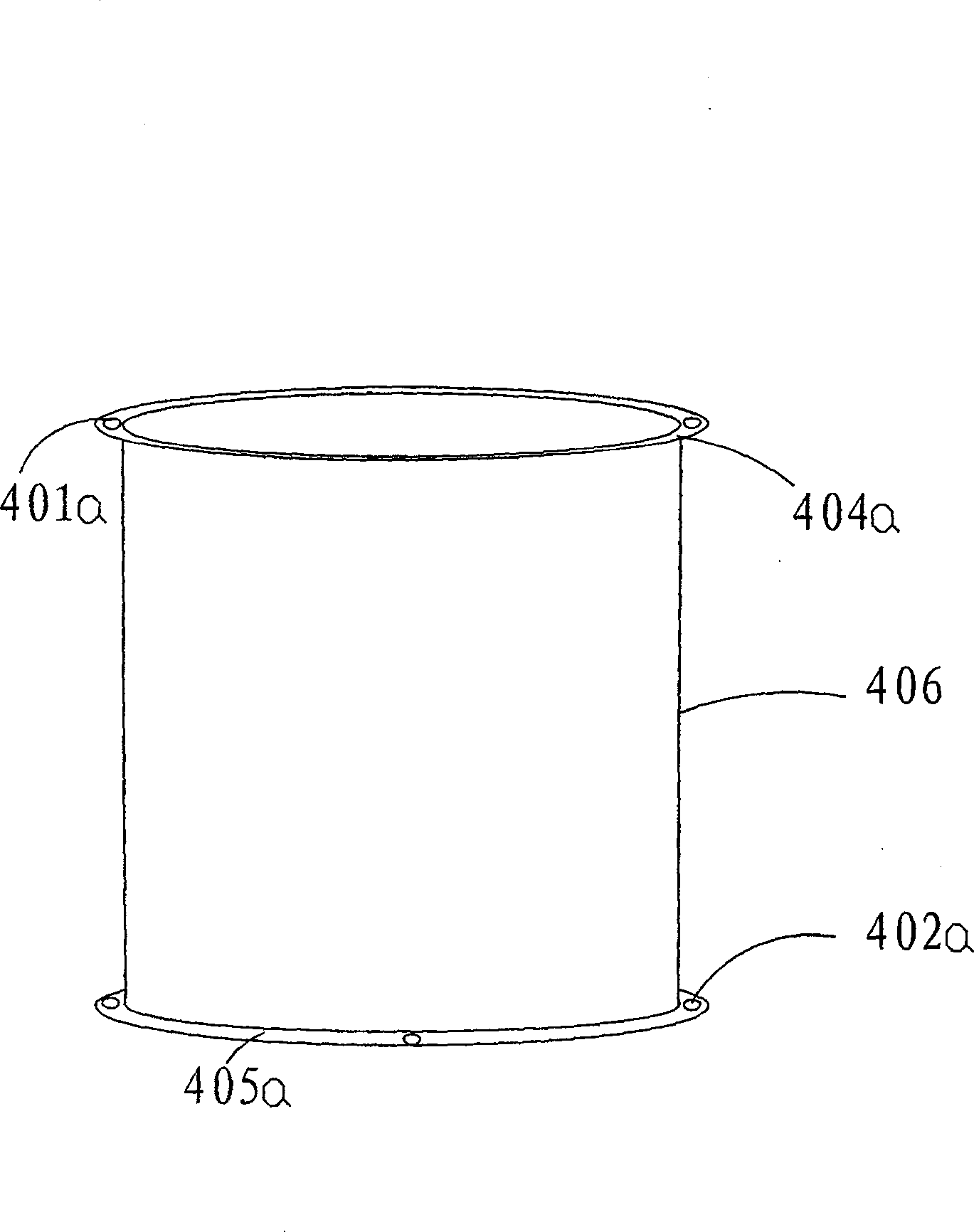

[0013] The serial numbers in the figure indicate respectively: upper end cover 10, end face 101, screw hole 102, through hole 103, screw hole 104; inner filter screen 20, cylindrical upper port 201, positioning skirt 202, fixing hole 203, filter hole 204; annular Filter paper 30, annular paper sheet 301, paper sheet through hole 302, gap 303; outer filter screen 40, fixing holes 401, 401a, fixing holes 402, 402a, filter hole 403, positioning skirt 404, annular ring 404a, 405a, positioning Skirt 405 , support rod 406 , lower end cover 50 , through hole 501 , and positioning groove 502 .

[0014] Referring to Fig. 1 (the ring-shaped sheet of paper positioned at the lower end surface of the filter paper 30 is drawn at the end of the figure), the upper and lower ends of this filter element are respectively an upper end cover 10 and a lower end cover 50, and the shapes and structures of the upper and lower end covers are completely consistent and face each other. set up. The middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com