A hermetic polytetrafluoroethylene valve for controlling fluid flow

A polytetrafluoroethylene, fluid control technology, applied in the direction of lift valve, valve detail, safety valve, etc., can solve the problems of leakage at the adjustment shaft, seal packing wear, valve deformation, etc., to reduce waste, simplify assembly, and reduce processing program effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The experimental invention will be described in further detail below in conjunction with the accompanying drawings.

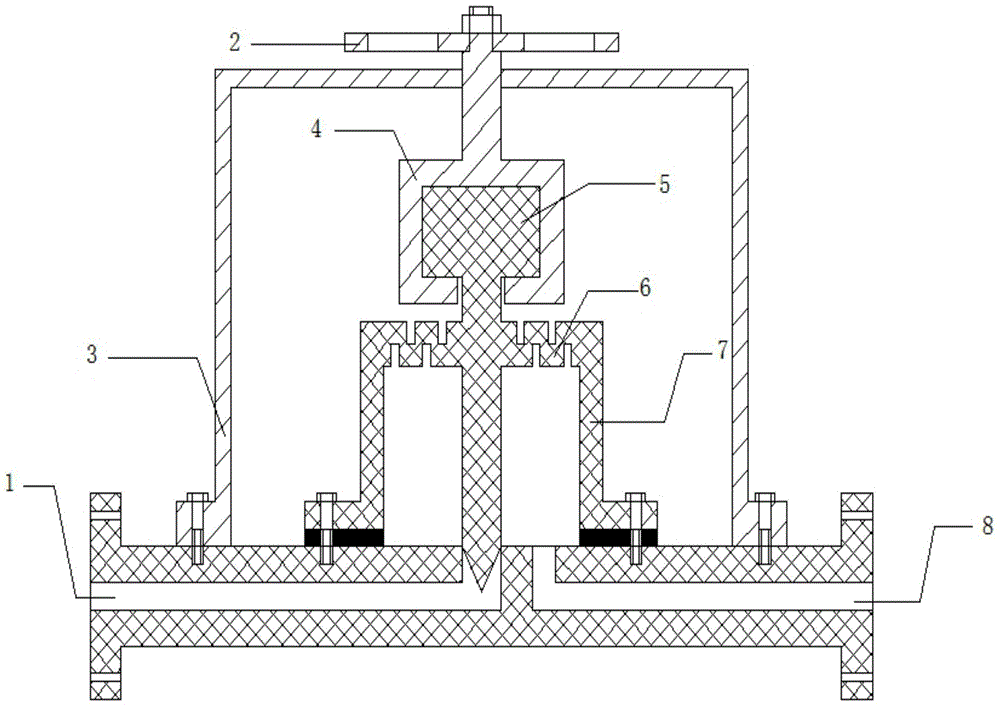

[0012] Such as figure 1 Shown is a schematic structural diagram of a hermetic polytetrafluoroethylene valve for controlling fluid flow. The valve includes an inlet channel 1, a handle 2, a valve cover 3, a valve casing 4, a valve core 5, a flexible connecting member 6, a valve inner bracket 7 and The outlet channel 8; the valve outer cover 3 is fixed on the inlet channel 1 and the outlet channel 8 through screw connection; the valve inner bracket 7 is fixed on the inlet channel 1 and the outlet channel 8 through screw connection; the valve inner bracket 7 is provided with a tapered rod and The telescopic connecting member 6; the top of the valve core 5 is a T-shaped cylindrical structure and matches with the inside of the valve housing 4; the bottom of the valve core 5 is a conical head and cooperates with the inlet channel 1; the handle 2 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com