Ultrahigh-strength steel sheet superior in hydrogen-embrittlement resistance

A thin steel plate, tensile strength technology, applied in the direction of temperature control, etc., can solve the problems of poor mechanical production efficiency, and achieve the effect of improving hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

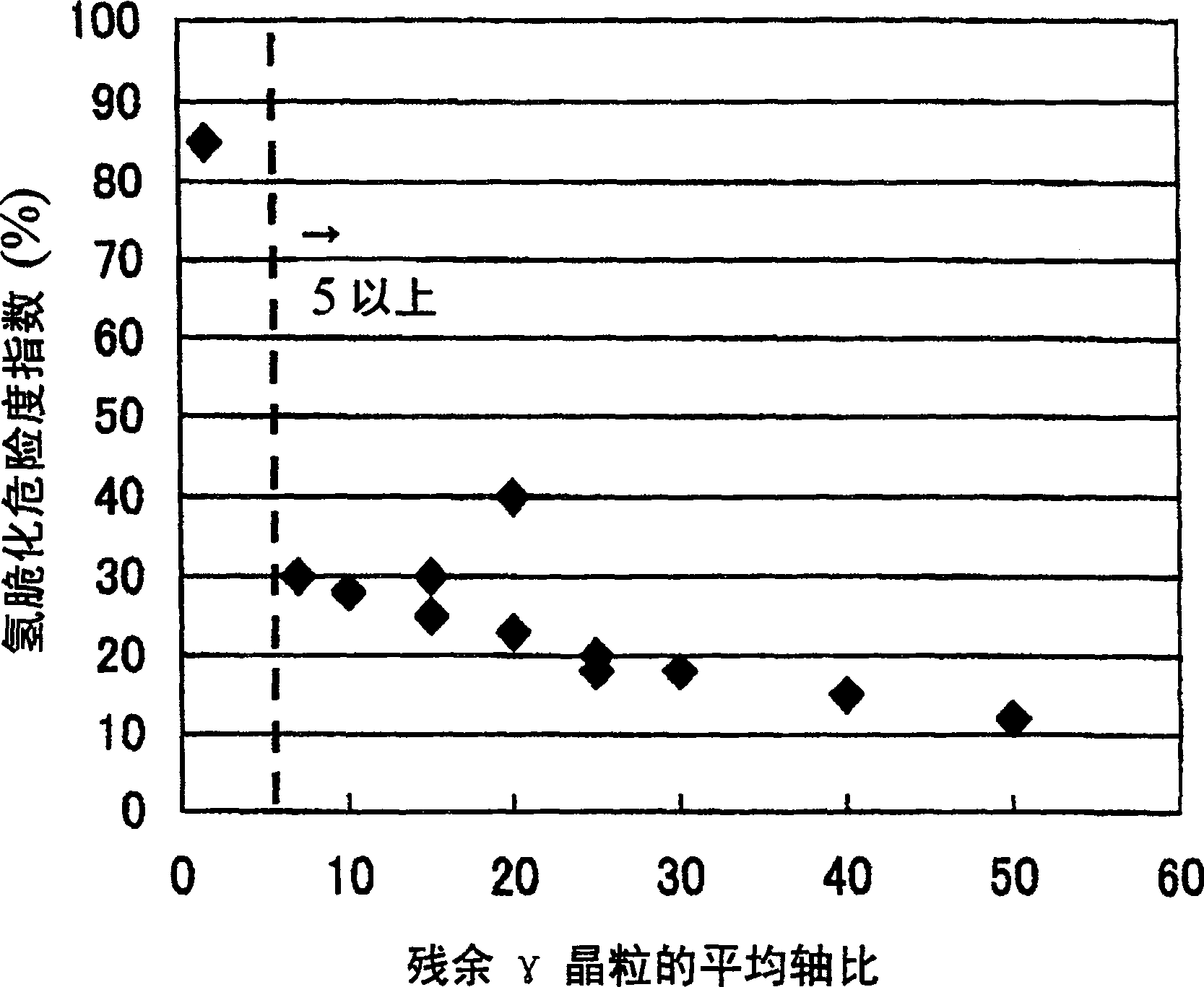

[0057] The ultrahigh-strength thin steel sheet according to Embodiment 1 of the present invention is characterized by containing C: 0.10 to 0.25%, Si: 1.0 to 3.0%, Mn: 1.0 to 3.5%, and P: 0.15% or less in mass percent , S: 0.02% or less, Al: 1.5% or less (excluding 0%), and also contains iron and unavoidable impurities as the rest, and contains more than 1% of residual austenite in terms of the area ratio of the entire structure. Bainitic ferrite and martensite totaling more than 80%, and ferrite and pearlite totaling less than 9% (including 0%). Wherein the average axial ratio (major axis / short axis) of the retained austenite grains is 5 or more, and the tensile strength is 1180 MPa or more. The reason for specifying these conditions, the measurement method, etc. are explained below.

[0058]

[0059] Retained austenite is not only useful for improving the total elongation, but also greatly contributes to the improvement of hydrogen embrittlement resistance, so it is made ...

Embodiment approach 2

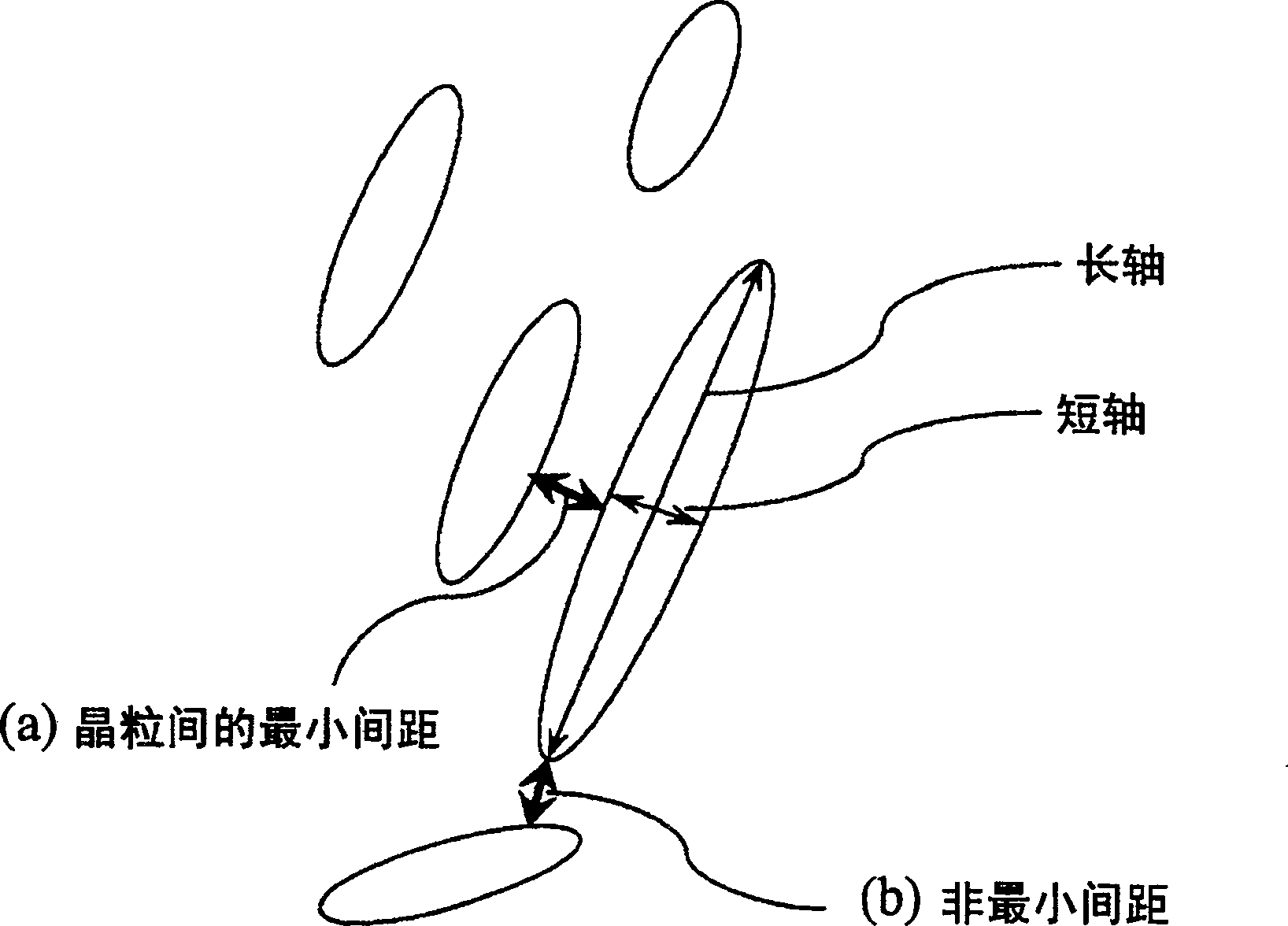

[0129] The ultrahigh-strength steel sheet according to Embodiment 2 of the present invention is characterized by containing C: 0.10 to 0.25%, Si: 1.0 to 3.0%, Mn: 1.0 to 3.5%, and P: 0.15% or less in mass percent , S: 0.02% or less, Al: 1.5% or less (excluding 0%), and the rest are composed of iron and unavoidable impurities, which contain more than 1% of retained austenite in terms of the area ratio of the entire structure, totaling More than 80% of bainitic ferrite and martensite, and a total of less than 9% (including 0%) of ferrite and pearlite, and the average minor axis length of the retained austenite grains is 1 μm or less, and the closest adjacent distance between the retained austenite grains is 1 μm or less, the average axis ratio (major axis / short axis) of the retained austenite grains is 5 or more, and the tensile strength is 1180 MPa or more . Here, a total of 80% or more of bainitic ferrite and martensite, and / or a total of 9% or less (including 0%) of ferrite ...

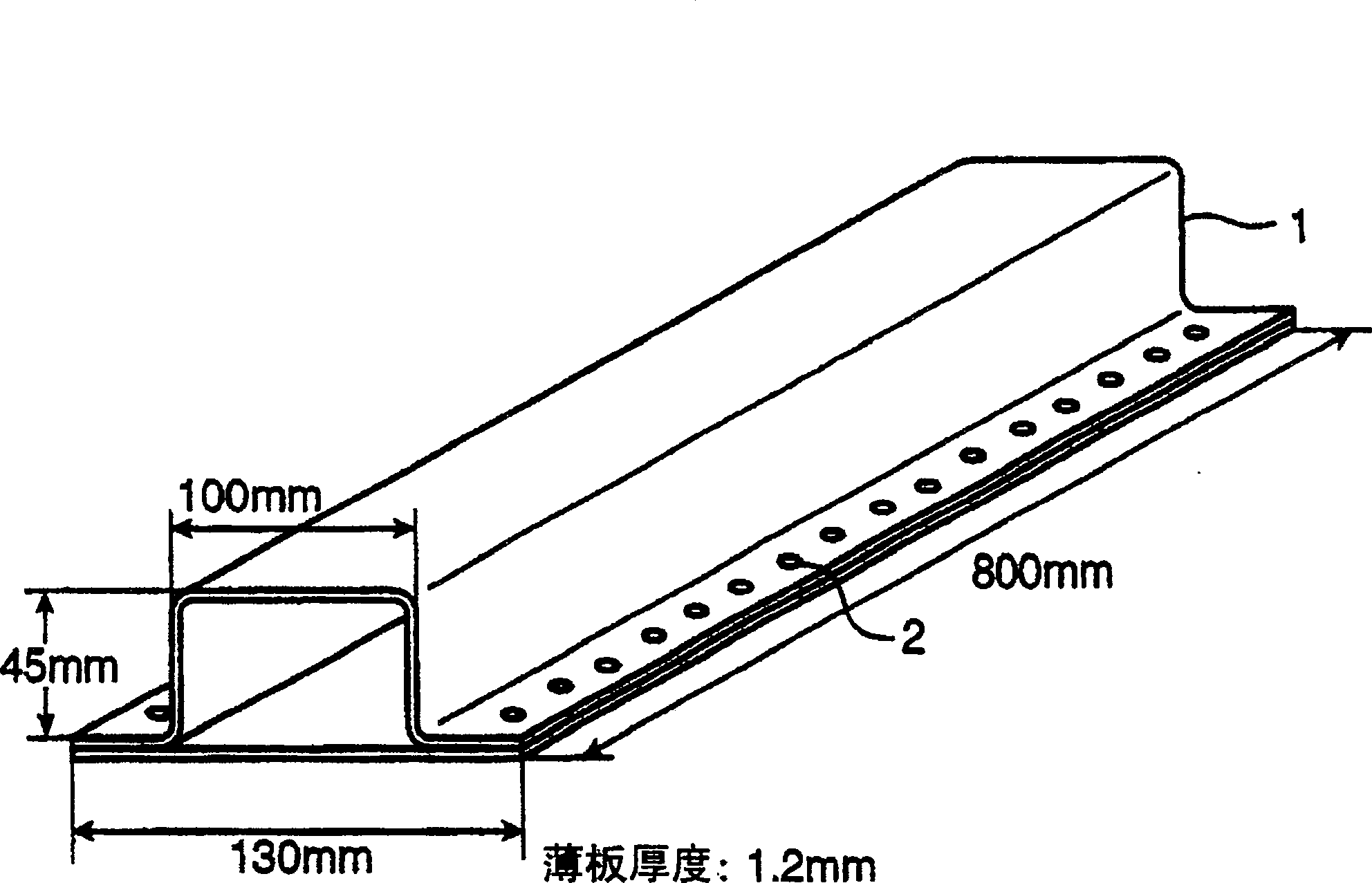

Embodiment 1

[0138] The experimental steel No.A-1~Y-1 composed of the composition listed in Table 1 was vacuum smelted to make the slab for the experiment, followed by the following procedures (hot rolling→cold rolling→continuous annealing) to obtain a plate thickness of 3.2 After the hot-rolled steel sheet of mm, the surface scale was removed by pickling, and then cold-rolled until it became 1.2 mm thick. Start temperature (SRT) at : 1150~1250℃ for 30 minutes

[0139] Finish temperature (FDT): 850°C

[0140] Cooling rate: 40°C / s

[0141] Coiling temperature: 550°C

[0142] Cold rolling rate: 50%

[0143] For each experimental steel in the , after holding at point A3 + 30°C for 120 seconds, it was rapidly cooled (air-cooled) to To°C in Table 2 at an average cooling rate of 20°C / s, and held at this To°C at 240°C. seconds. Then air-water cooled to room temperature.

[0144] In addition, No. 116 in Table 2 is used as a comparative example. In order to produce a martensitic steel of con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com